Coated slow-release organic fertilizer and preparation method thereof

An organic fertilizer, slow-release technology, applied in layered/coated fertilizers, fertilizer mixtures, nitrogen fertilizers, etc., can solve the problems of easy peeling, poor slow-release performance, adverse effects of slow-release performance, etc., to avoid wear consumption, The effect of good protection and isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

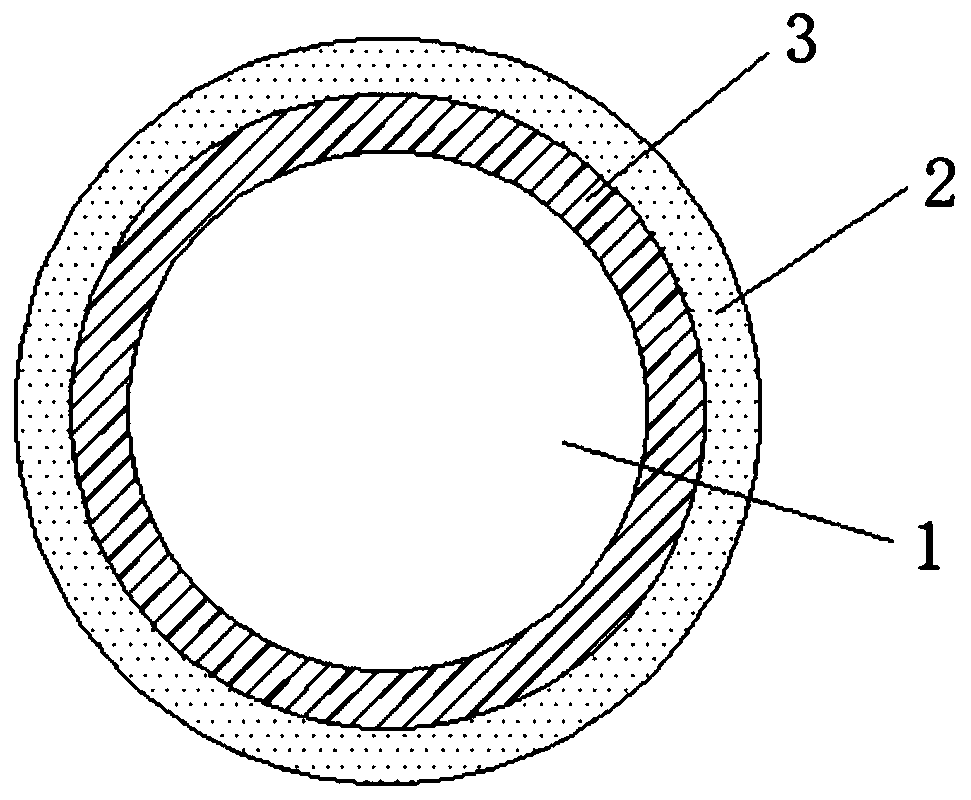

[0033] A coated slow-release organic fertilizer is composed of urea nuclei with a particle size of 1-5 mm and a coating, and the coating is composed of an inner slow-release layer and an outer isolation layer;

[0034] The sustained-release layer comprises the following components in weight percent:

[0035] Carbon-based loaded layered double hydroxide 62%, chitosan 30%, tung oil 8%.

[0036] The isolation layer is styrene-acrylic emulsion-paraffin-phosphogypsum material.

[0037] The preparation method of carbon-based loaded layered double hydroxide is as follows:

[0038] (1) Wash the peanut shells, dry them, crush them, and sieve them, then add them to concentrated phosphoric acid at 50°C for 10 hours and then filter them out. The solid-to-liquid mass ratio of peanut shells to concentrated phosphoric acid is 1:8. Stir in dilute hydrochloric acid for 35 minutes, then dry, place in a muffle furnace and heat up to 120°C for 3 hours, then heat up to 200°C for 2 hours at a rat...

Embodiment 2

[0045] A coated slow-release organic fertilizer is composed of urea nuclei with a particle size of 1-5 mm and a coating, and the coating is composed of an inner slow-release layer and an outer isolation layer;

[0046] The sustained-release layer comprises the following components in weight percent:

[0047]Carbon-based loaded layered double hydroxide 60%, chitosan 35%, tung oil 5%.

[0048] The isolation layer is styrene-acrylic emulsion-paraffin-phosphogypsum material.

[0049] The preparation method of carbon-based loaded layered double hydroxide is as follows:

[0050] (1) Wash the peanut shells, dry them, crush them, and sieve them, then add them to concentrated phosphoric acid at 60°C for 5 hours and then filter them out. The solid-to-liquid mass ratio of peanut shells to concentrated phosphoric acid is 1:8. Stir in dilute hydrochloric acid for 30 minutes, then dry, place in a muffle furnace and heat up to 130°C for 2 hours, then heat up to 180°C for 2 hours at a rate ...

Embodiment 3

[0057] A coated slow-release organic fertilizer is composed of urea nuclei with a particle size of 1-5 mm and a coating, and the coating is composed of an inner slow-release layer and an outer isolation layer;

[0058] The sustained-release layer comprises the following components in weight percent:

[0059] Carbon-based loaded layered double hydroxide 65%, chitosan 30%, tung oil 5%.

[0060] The isolation layer is styrene-acrylic emulsion-paraffin-phosphogypsum material.

[0061] The preparation method of carbon-based loaded layered double hydroxide is as follows:

[0062] (1) Wash the peanut shells, dry them, crush them, and sieve them, then add them to concentrated phosphoric acid at 60°C for 5 hours and then filter them out. The solid-to-liquid mass ratio of peanut shells to concentrated phosphoric acid is 1:6. Stir in dilute hydrochloric acid for 30 minutes, then dry it, place it in a muffle furnace and heat it up to 130°C for 1 hour, then heat it up to 200°C for 2 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com