Modified nano-silica plugging agent, water-based drilling fluid, and preparation methods and applications of modified nano-silica plugging agent and water-based drilling fluid

A technology of nano-silica and water-based drilling fluid, which is applied in the field of drilling fluid and can solve the problems of small particle size, large specific surface energy and easy agglomeration of nano-blocking materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

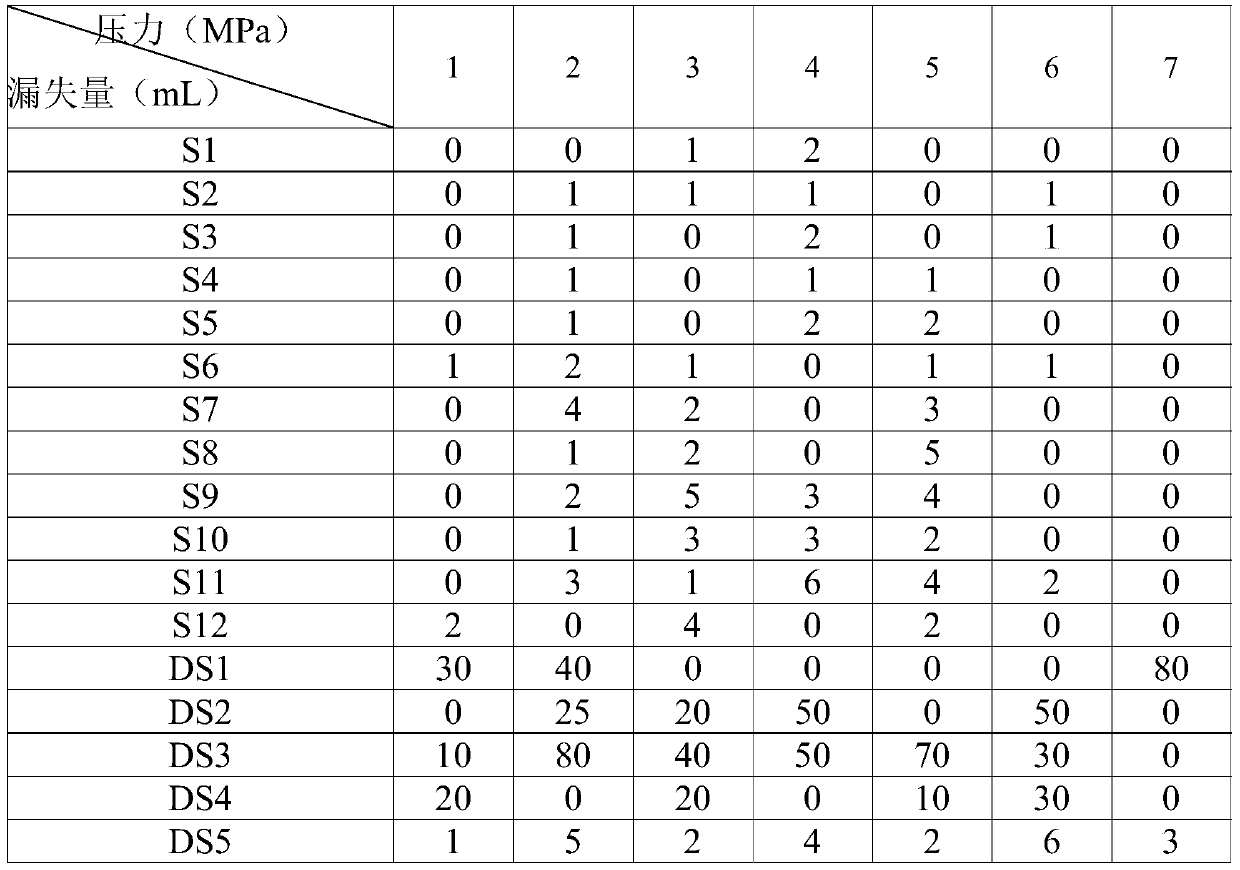

Image

Examples

preparation example Construction

[0024] The first aspect of the present invention provides a kind of preparation method of modified nano silica plugging agent, and this method comprises:

[0025] (1) contacting nano-silica with a mixed solution containing acrylic acid and polybutylmethacrylate and carrying out ultrasonic dispersion treatment to obtain an oil phase solution;

[0026] (2) Contacting water, polyethylene glycol octylphenyl ether and sodium bicarbonate and performing the first emulsification treatment to obtain the first emulsification solution;

[0027] (3) contacting the oil phase solution with the first emulsified solution and performing a second emulsified treatment to obtain a second emulsified solution;

[0028] (4) Under the protection of nitrogen, the second emulsified solution is contacted with a water-soluble initiator, and the product obtained after the contact is centrifuged and dried to obtain a plugging agent.

[0029] According to the present invention, in step (1), the weight rati...

Embodiment 1

[0077] This example is to illustrate the plugging agent and water-based drilling fluid prepared by the method of the present invention.

[0078] (1) Under the condition that the stirring rate is 100r / min, the particle diameter of 5 parts by weight is that the nano silicon dioxide of 20nm is added in the mixed solution of the acrylic acid of 13 parts by weight, the polybutylmethacrylate of 3 parts by weight , and in a ultrasonic emulsification disperser, disperse for 1h under the condition of an ultrasonic frequency of 20kHz to obtain an oil phase solution;

[0079] (2) In 50 parts by weight of deionized water, add 0.5 parts by weight of polyethylene glycol octyl phenyl ether and sodium bicarbonate of 0.3 parts by weight successively, and pre-emulsify for 6 minutes under the condition that the stirring speed is 100r / min, and obtain The weakly alkaline first emulsified solution with a pH value of 8;

[0080] (3) Add the oil phase solution to the first emulsified solution, and e...

Embodiment 2

[0086] This example is to illustrate the plugging agent and water-based drilling fluid prepared by the method of the present invention.

[0087] (1) Under the condition that the stirring rate is 100r / min, the particle diameter of 2 parts by weight is the nano silicon dioxide of 20nm is added in the mixed solution of the acrylic acid of 5 parts by weight, the polybutylmethacrylate of 0.2 parts by weight , and in a ultrasonic emulsification disperser, disperse for 0.8h under the condition of an ultrasonic frequency of 20kHz to obtain an oil phase solution;

[0088] (2) In 50 parts by weight of deionized water, add 0.1 parts by weight of polyethylene glycol octyl phenyl ether and sodium bicarbonate of 0.1 parts by weight successively, and pre-emulsify for 2 minutes under the condition that the stirring speed is 100r / min, and obtain The weakly alkaline first emulsified solution with a pH value of 7;

[0089] (3) Add the oil phase solution to the first emulsified solution, and emu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com