Mannich base acidizing corrosion inhibitor and preparation method thereof

An acidification corrosion inhibitor and Mannich base technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of poor solubility, dispersion and slow release, and achieve excellent high temperature resistance and Highlight, promote adsorption, and promote the effect of dissolution and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

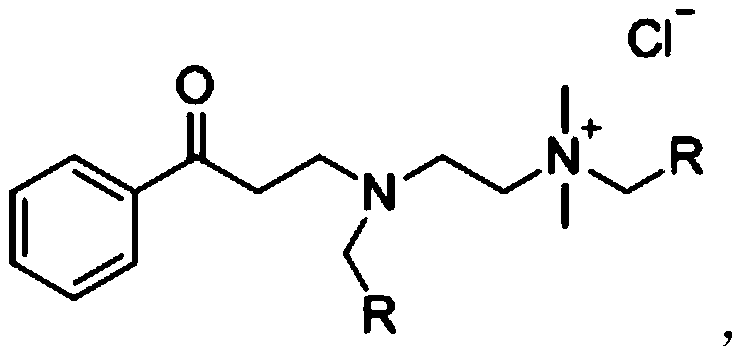

[0029] The structural formula of the Mannich base acidification corrosion inhibitor of the present embodiment is as follows:

[0030]

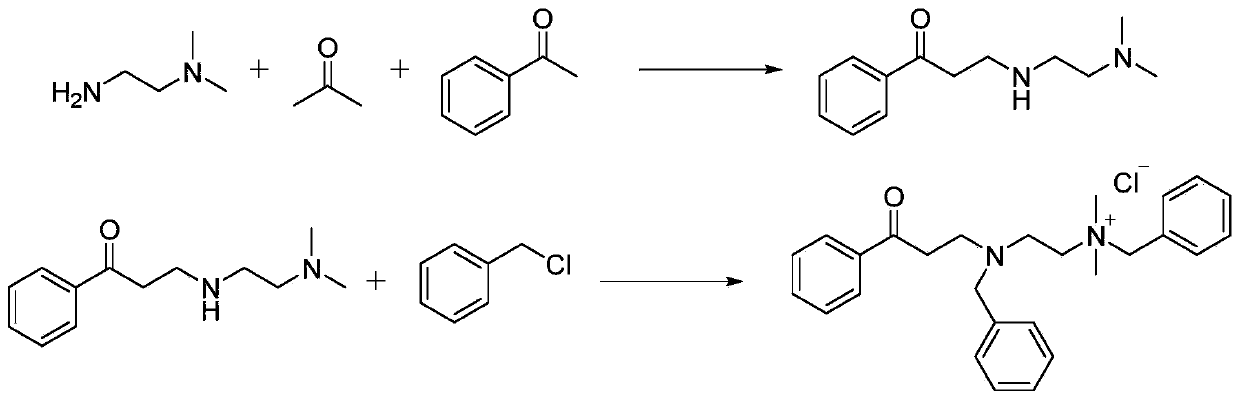

[0031] Its preparation process route is:

[0032]

[0033] The preparation method of the Mannich base acidification corrosion inhibitor of the present embodiment comprises the following steps:

[0034] (1) Put 30g of paraformaldehyde into a 1000ml three-necked flask, add 100ml of ethanol and stir; take 88g of N,N-dimethylethylenediamine, dissolve it in 50ml of ethanol, slowly drop it into the flask, and heat up to 60°C React for 2 hours; add concentrated hydrochloric acid to the flask to adjust the pH to 2-3, add 120 g of acetophenone, raise the temperature to 80° C. and react for 8-12 hours to obtain a dark brown liquid that is Mannich base solution.

[0035] (2) After the above liquid is cooled to room temperature, add an appropriate amount of 30% sodium hydroxide solution to adjust the pH of the solution to 8-9, add 253g of benzyl ch...

Embodiment 2

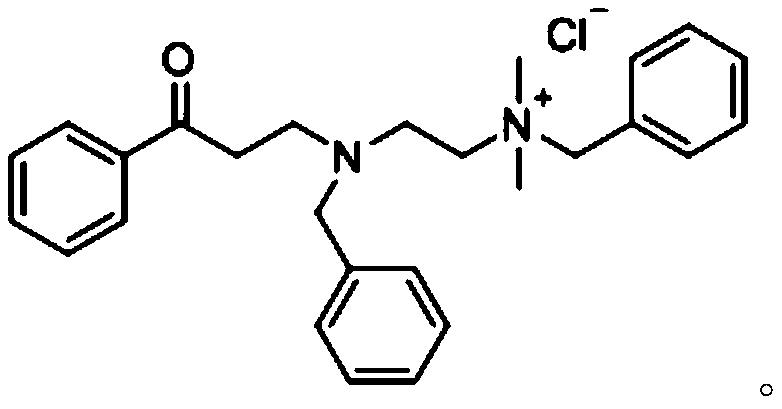

[0043] The structural formula of the Mannich base acidification corrosion inhibitor of the present embodiment is as follows:

[0044]

[0045] Its preparation process route is:

[0046]

[0047] The preparation method of the Mannich base acidification corrosion inhibitor of the present embodiment comprises the following steps:

[0048] (1) Put 30g of paraformaldehyde into a 1000ml three-neck flask, add 100ml of ethanol and stir; take 88g of N,N-dimethylethylenediamine, dissolve it in 50ml of ethanol, slowly drop it into the flask, and heat up to 60°C React for 2 hours; add concentrated hydrochloric acid to the flask to adjust the pH to 2-3, add 120 g of acetophenone, raise the temperature to 80° C. and react for 8-12 hours to obtain a dark brown liquid that is Mannich base solution.

[0049] (2) After the above liquid is cooled to room temperature, add an appropriate amount of 30% sodium hydroxide solution to adjust the pH of the solution to 8-9, add 353g of 2-(chlorome...

Embodiment 3

[0057] The structural formula of the Mannich base acidification corrosion inhibitor of the present embodiment is as follows:

[0058]

[0059] Its preparation process route is:

[0060]

[0061] The preparation method of the Mannich base acidification corrosion inhibitor of the present embodiment comprises the following steps:

[0062] (1) Put 30g of paraformaldehyde into a 1000ml three-necked flask, add 100ml of ethanol and stir; take 88g of N,N-dimethylethylenediamine, dissolve it in 50ml of ethanol, slowly drop it into the flask, and heat up to 60°C React for 2 hours; add concentrated hydrochloric acid to the flask to adjust the pH to 2-3, add 120 g of acetophenone, raise the temperature to 80° C. and react for 8-12 hours to obtain a dark brown liquid that is Mannich base solution.

[0063] (2) After the above liquid is cooled to room temperature, add an appropriate amount of 30% sodium hydroxide solution to adjust the pH of the solution to 8-9, add 453g of 9-chlorom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com