A method and system for determining the position of a force measuring wheel pair strain gauge

A force measuring wheel set and a technology for determining a method, which are applied to measuring devices, force/torque/power measuring instruments, force/torque/power measuring instrument calibration/testing, etc., can solve the problem of insufficient operational reliability and poor accuracy of force measurement advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

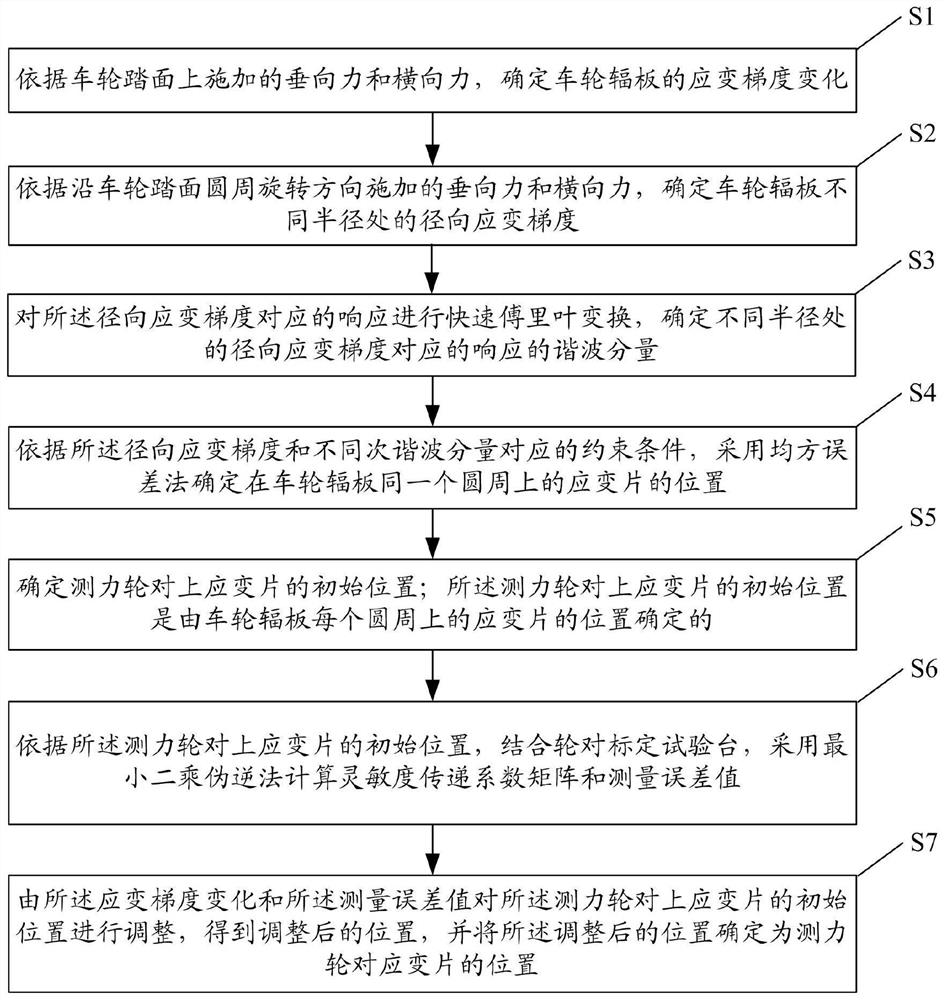

[0077] figure 1 It is a flow chart of a method for determining the position of a force measuring wheel pair of strain gauges in Embodiment 1 of the present invention. see figure 1 , the method for determining the position of the force measuring wheel pair of strain gauges in this embodiment includes:

[0078] Step S1: Determine the strain gradient change of the wheel web according to the vertical force and lateral force applied on the wheel tread.

[0079] Step S2: Determine the radial strain gradient at different radii of the wheel web plate according to the vertical force and lateral force applied along the rotation direction of the wheel tread circumference.

[0080] The step S2 specifically includes:

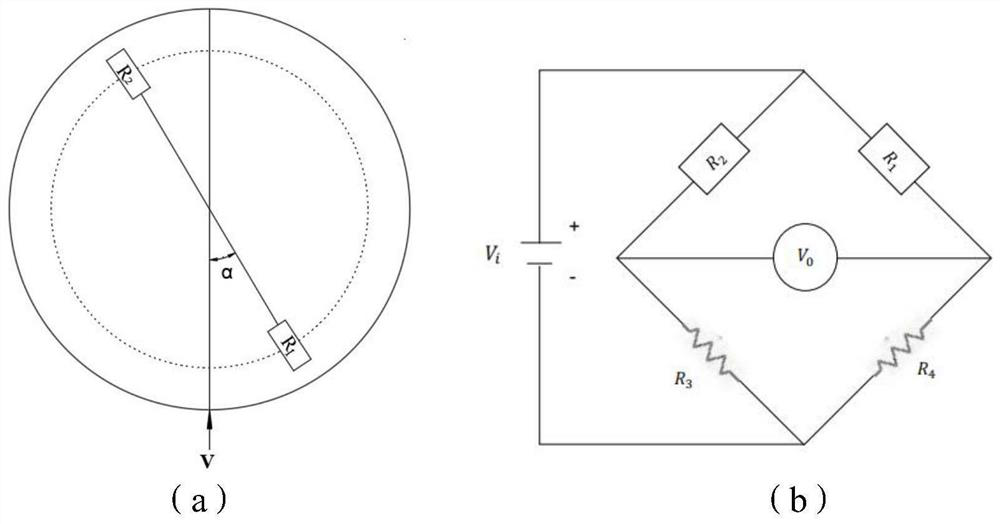

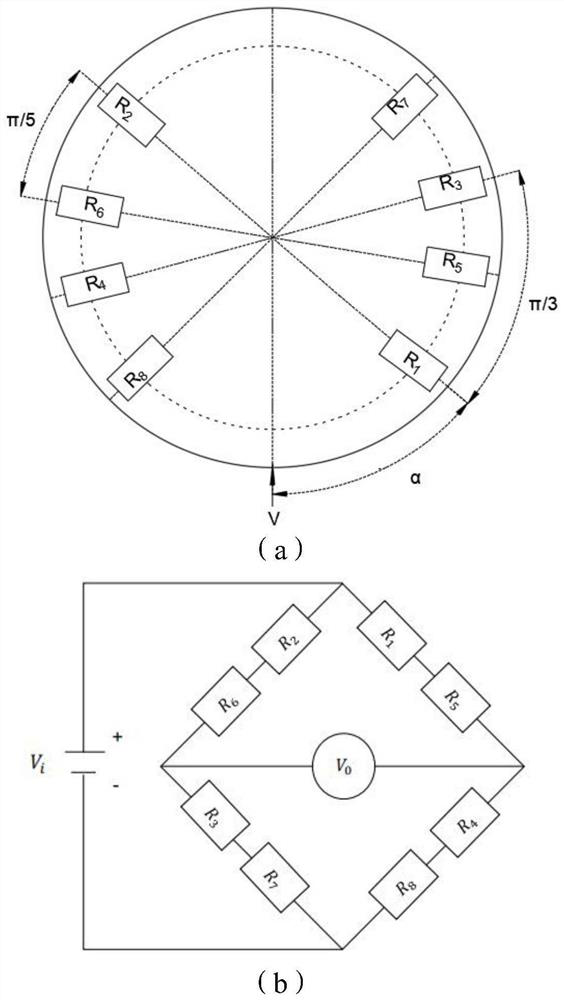

[0081] According to the radial strain gradient and even-order harmonic constraint conditions, the first included angle is determined by using the mean square error method; the first included angle is the included angle between the first strain gauge and the second strain ...

Embodiment 2

[0109] Aiming at the problems of low test accuracy, insufficient operation reliability, oversimplified calibration method, no consideration of the influence of wheel wear, and difficulty in long-term follow-up testing of existing force-measuring wheel sets, an optimal strain measurement method for force-measuring wheelsets was proposed. Chip layout optimization and least square error control calibration, by strengthening the optimal layout control of the measurement connection system, by using neural network technology to analyze and diagnose the test system, in order to improve the test accuracy of the force measuring wheel set, with high A dynamometric wheel set method for operational reliability and self-diagnostic test system failure function.

[0110] The train of thought of the method for determining the position of the force measuring wheel pair strain gauges provided in this embodiment is as follows:

[0111] In order to determine the optimal arrangement of the strain ...

Embodiment 3

[0200] Such as Figure 5 As shown, the force measuring wheel pair strain gauge position determination system provided in this embodiment includes:

[0201] The gradient change determination module 501 is configured to determine the strain gradient change of the wheel web according to the vertical force and lateral force applied on the wheel tread.

[0202] The radial strain value calculation module 502 is used to determine the radial strain gradient at different radii of the wheel web according to the vertical force and lateral force applied along the wheel tread circumferential rotation direction.

[0203] The harmonic component calculation module 503 is configured to perform fast Fourier transform on the response corresponding to the radial strain gradient, and determine the harmonic component of the response corresponding to the radial strain gradient at different radii.

[0204] The strain gauge position determination module 504 is configured to determine the position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com