Electromagnetic sound detection robot for storage tank

An electromagnetic acoustic and robot technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of wall-climbing robots, such as difficulty in turning, difficulty in realizing thickness and cracks, and unreliable adsorption, etc., to achieve easy full-coverage online detection and maintain high efficiency Reliable, magnetic adsorption reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

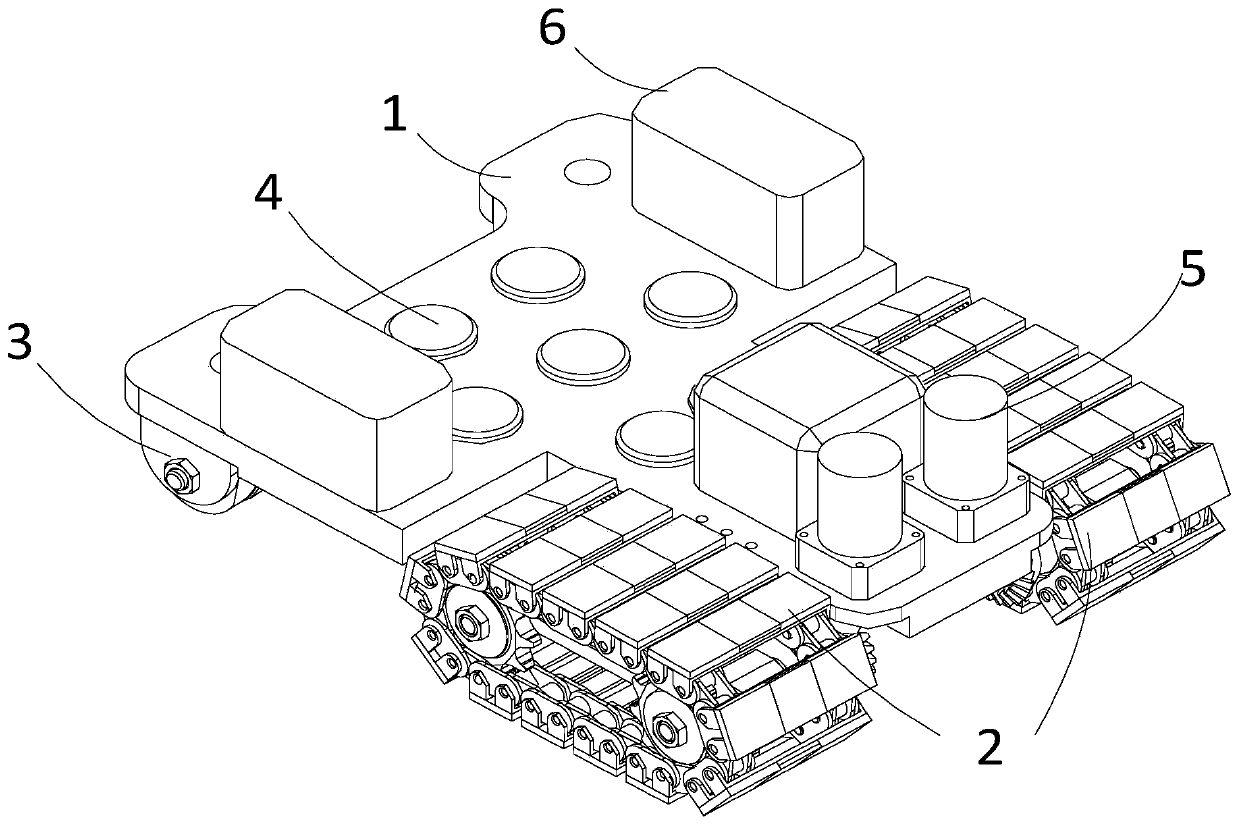

[0034] Such as Figure 1-4 As shown, a storage tank electromagnetic acoustic detection robot includes a frame 1, a walking assembly, a driving assembly 5, and an electromagnetic acoustic sensor. The driving assembly 5 is used to drive the walking assembly to move.

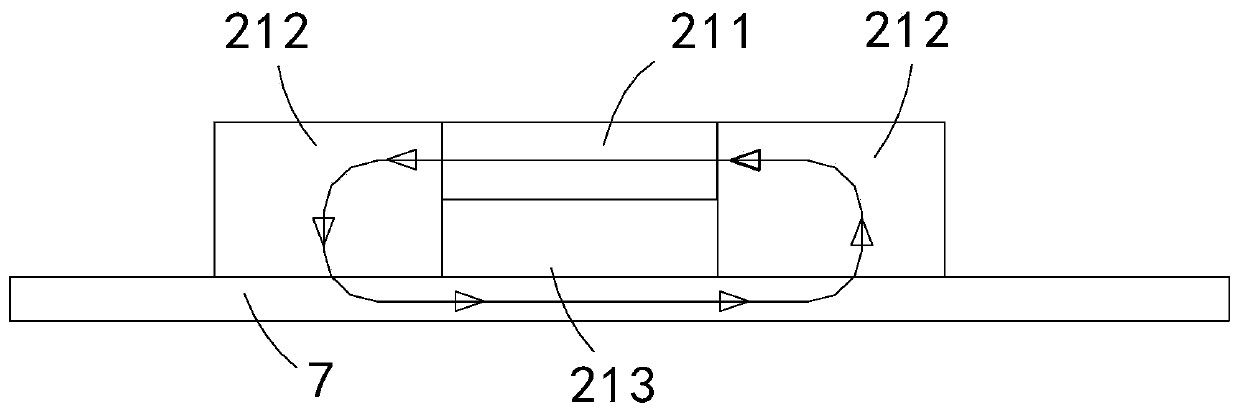

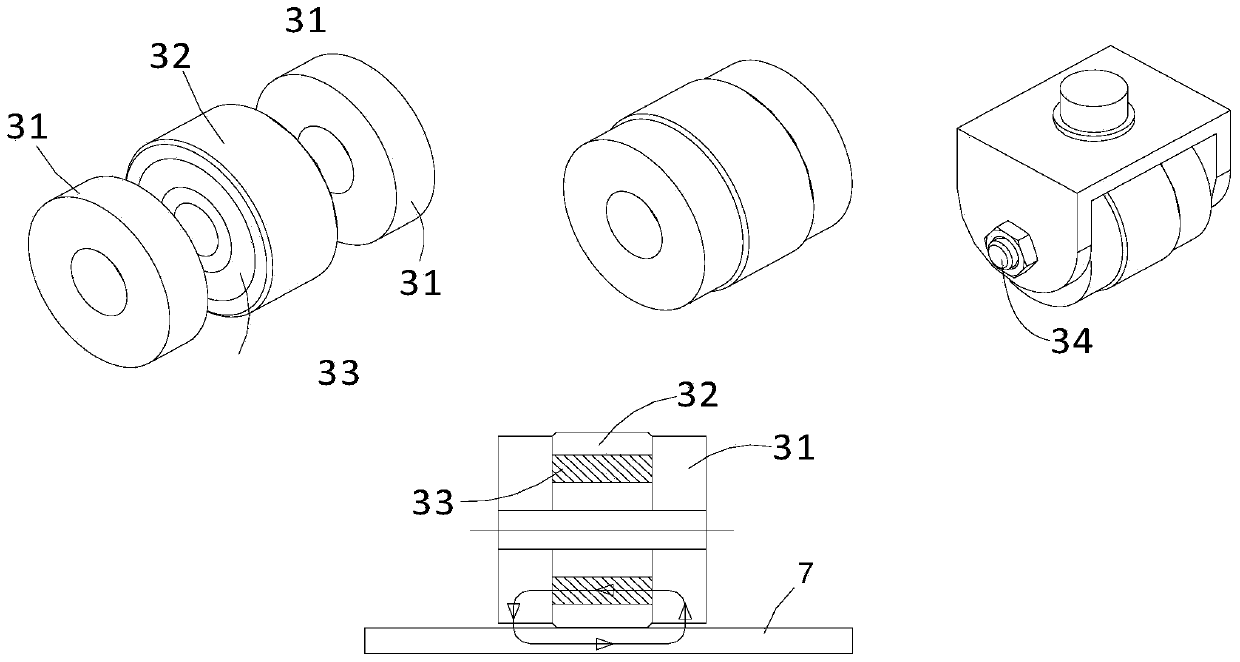

[0035] The walking assembly includes a magnetic mechanism adsorbed on the storage tank 7 . In this solution, the walking assembly includes a universal wheel unit 3 and a crawler unit 2 , and the drive assembly 5 drives the crawler unit 2 to move. There are two crawler units 2 and drive assemblies 5, which are symmetrically installed on both sides of the front of the frame 1, and two universal wheel units 3, which are symmetrically hinged and installed on both sides of the rear of the frame 1. The array of electromagnetic acoustic sensors and electromagnetic control unit 6 is in the middle of the rack 1 . The center of gravity of the robot is stable like this.

[0036] The outward wheel unit, the track unit 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com