Method for manufacturing monocrystalline silicon SE-PERC battery through secondary annealing

A technology of an infrared laser and a manufacturing method, applied in the field of solar cells, can solve the problems of reducing the photoelectric conversion efficiency, damage, open voltage and short-circuit current of crystalline silicon cells of a single crystal silicon SE-PERC cell, and reduce carriers. Compounding, improving open pressure and short flow, repairing the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

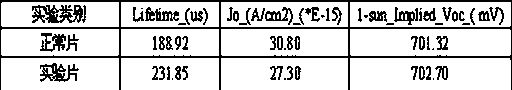

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

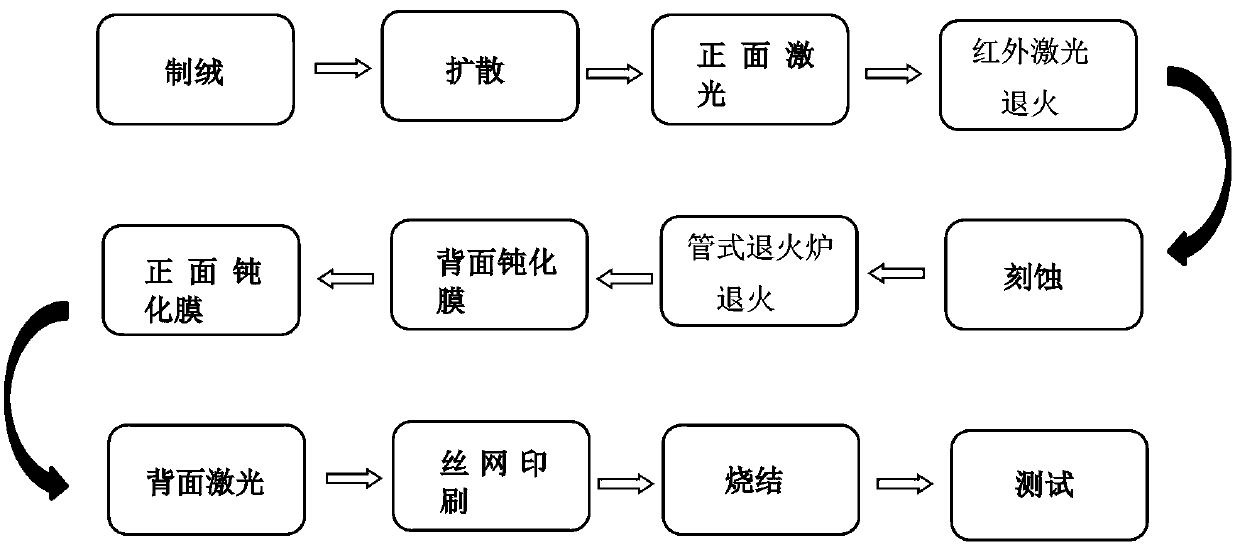

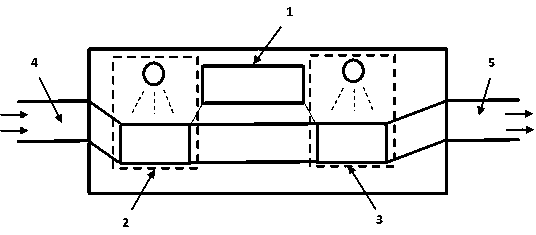

[0024] Such as Figure 1~2 Shown, a kind of manufacturing method of the monocrystalline silicon SE-PERC cell of infrared laser annealing, the step comprises:

[0025] 1. Texture making: use wet technology to form a textured surface on the surface of the P-type monocrystalline silicon wafer;

[0026] 2. Diffusion: P-N junction is formed by diffusion;

[0027] 3. Front laser: Prepare selective emitter, and use laser to do heavy doping on the surface of silicon wafer;

[0028] 4. Infrared laser annealing: Repair the damage caused by the front laser to the surface of the silicon wafer, passivate the surface to reduce the recombination of carriers.

[0029] 5. Etching: use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com