Axial magnetic flux leakage prevention three-rotor motor and assembling method thereof

An anti-magnetic flux leakage and three-rotor technology, which is applied in electric components, electromechanical devices, and motor generators, etc., can solve the problems of low actual conversion efficiency of mechanical energy of motors, and achieve reduced magnetic leakage, high power conversion rate, and improved conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

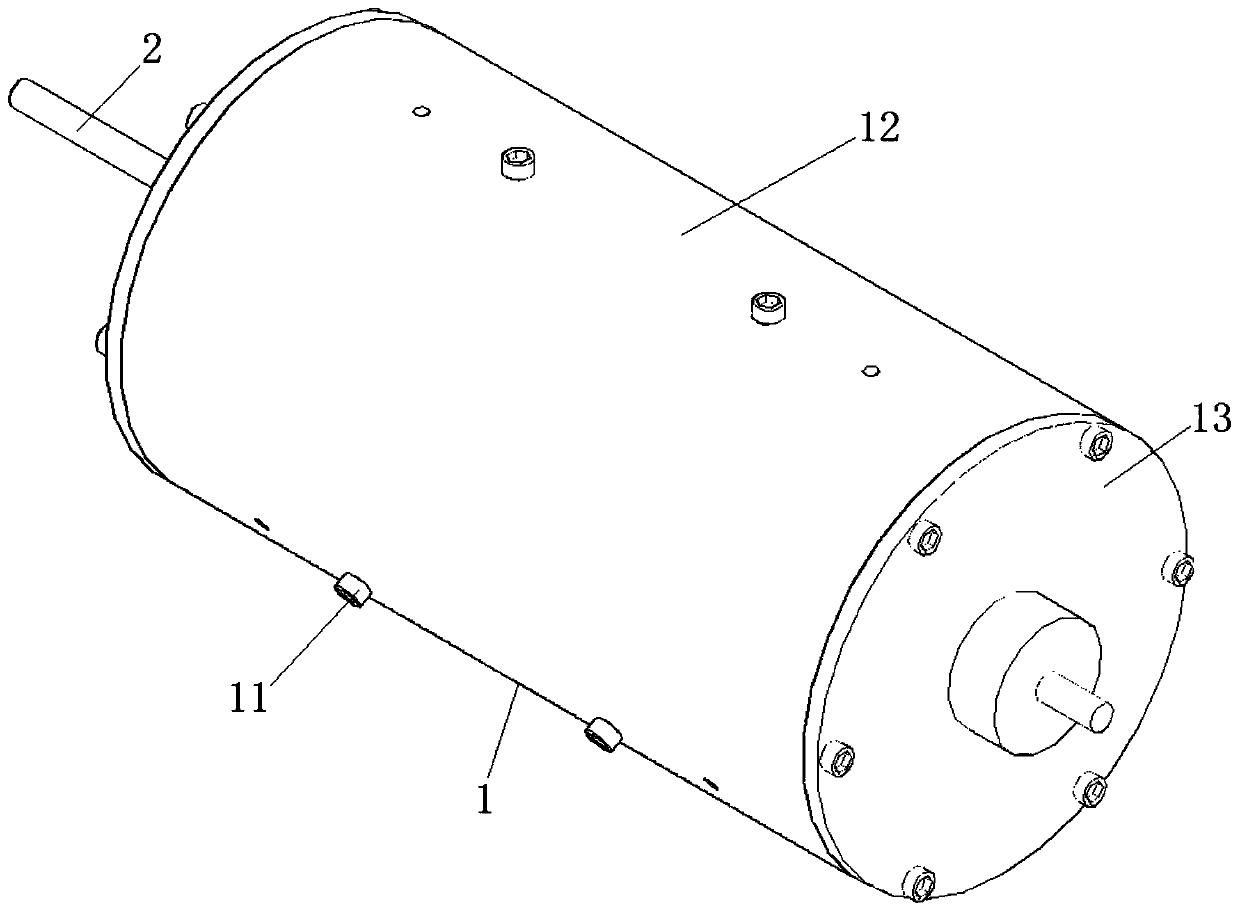

[0065] see figure 1 , the present embodiment provides an axially anti-leakage three-rotor motor, the motor adopts three sets of rotors, and can make full use of the magnetic energy generated by the stator. Wherein, the three-rotor motor includes a housing 1, a stepped shaft 2, a stator assembly and a rotor assembly. In some embodiments, the stepped shaft 2 and the rotor assembly can be combined into one structure.

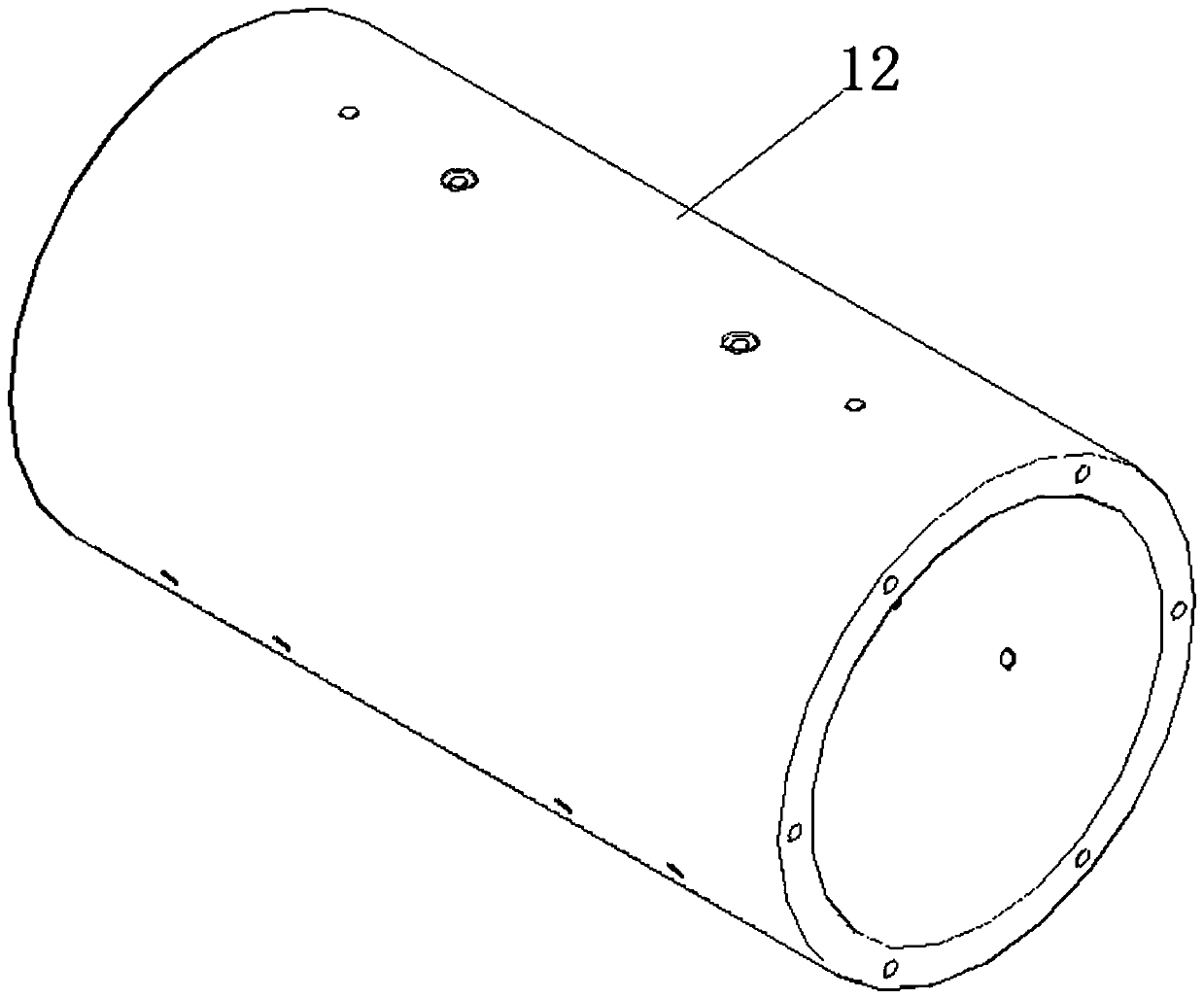

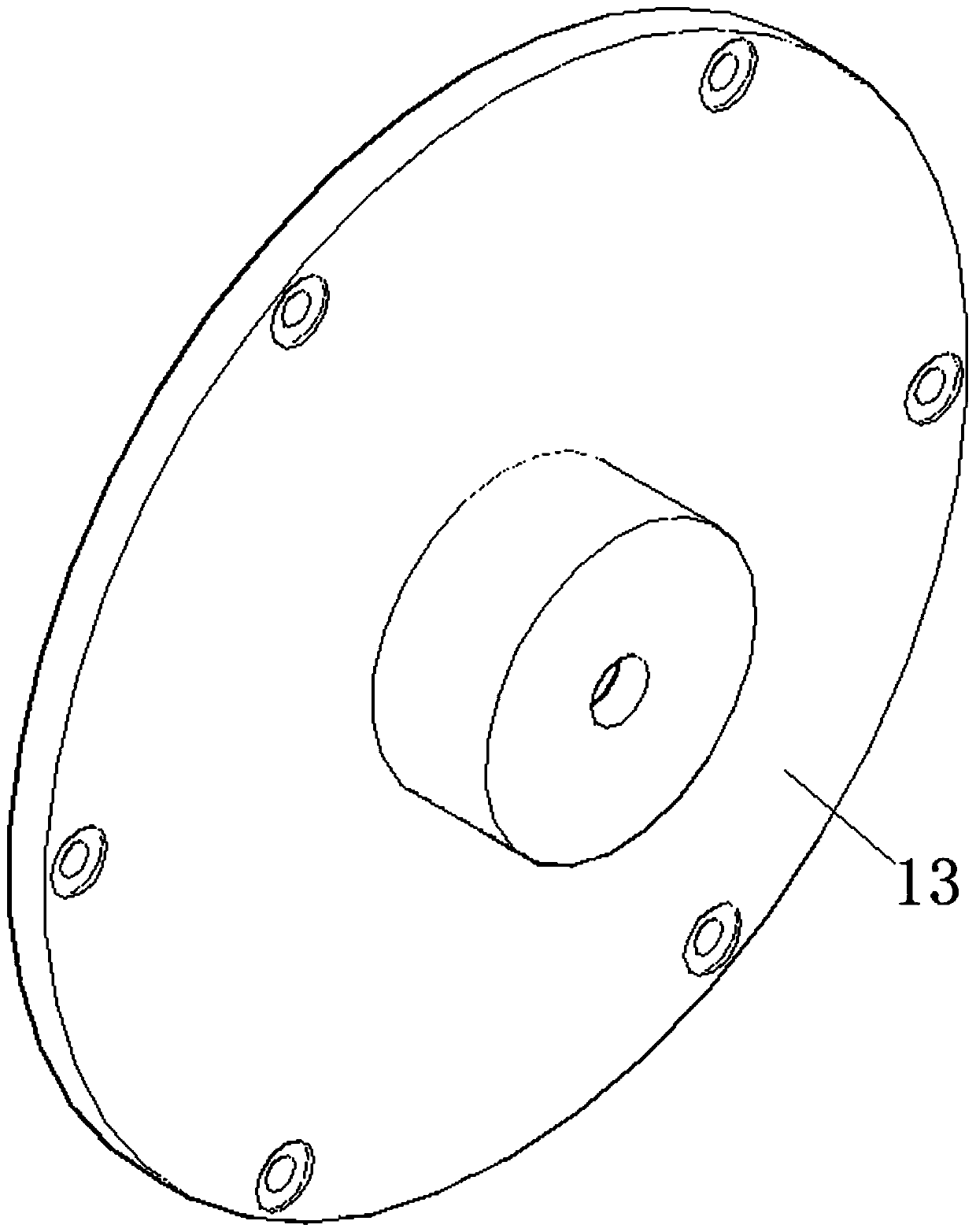

[0066] see figure 2 , image 3 as well as Figure 4 , In this embodiment, the housing 1 includes an outer cylinder 12 , an end cover 13 and an angular contact ball bearing 14 . The outer cylinder 12 is a cylindrical structure, and a plurality of positioning holes 102 are opened on its side wall. The number of end caps 13 is two, and the two end caps 13 cover the two ends of the outer cylinder 12 respectively. The two angular contact ball bearings 14 correspond to the two end caps 13 respectively, each angular contact ball bearing 14 is fixed on the correspond...

Embodiment 2

[0081] see Figure 16 , Figure 17 as well as Figure 18 , this embodiment provides a mold for prefabricating a stator assembly, and the mold is used for prefabricating the stator assembly of the three-rotor motor with axial flux leakage prevention in Embodiment 1. Wherein, the mold includes a sleeve 16 , an upper cover 17 and a lower cover 18 . The sleeve 16 has a space for accommodating the stator assembly, and the upper cover 17 is arranged coaxially with the sleeve 16 and installed on one end of the sleeve 16 . The lower cover 18 is arranged coaxially with the upper cover 17 and installed on the other end of the sleeve 16 . Both the upper cover 17 and the lower cover 18 have limiting holes 28 for limiting the rotation of the stator assembly, and the ends of the silicon steel sheets are limited in the limiting holes 28 . The sleeve 16 defines a plurality of fixing holes 22 through which the positioning members 19 pass.

Embodiment 3

[0083] This embodiment provides an assembly method for a three-rotor motor, which is applied to the three-rotor motor with axial flux leakage prevention in Embodiment 1, and the assembly method includes the following steps.

[0084] 1. Using a curing agent 10 to fix a plurality of silicon steel sheets into the stator core 4 , and insert the inner sleeve 3 into the stator core 4 . Here, the assembly of the stator core 4 can be realized through structures such as molds.

[0085] 2. The casing 1 , the outer casing 5 , the stator core 4 and the inner casing 3 are fixed by a plurality of stud casings 11 . The shell 1, the outer sleeve 5, and the stator core 4 can be provided with through holes for the stud sleeve 11, while the inner sleeve 3 can be provided with blind holes to position the end of the stud sleeve 11.

[0086] 3. Put the inner magnetic ring 8 on the stepped shaft 2, and insert the inner magnetic ring 8 and the stepped shaft 2 into the inner sleeve 3. The inner magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com