Bidirectional extrusion oily sludge treatment device

A two-way extrusion and sludge treatment technology, which is applied in sludge treatment, water/sludge/sewage treatment, liquid separation, etc., can solve the problems of sludge accumulation, increased thickness of oil-water transition layer, and reduced efficiency, etc., to achieve Avoid the accumulation of material at the tail, improve efficiency and increase the effect of extrusion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

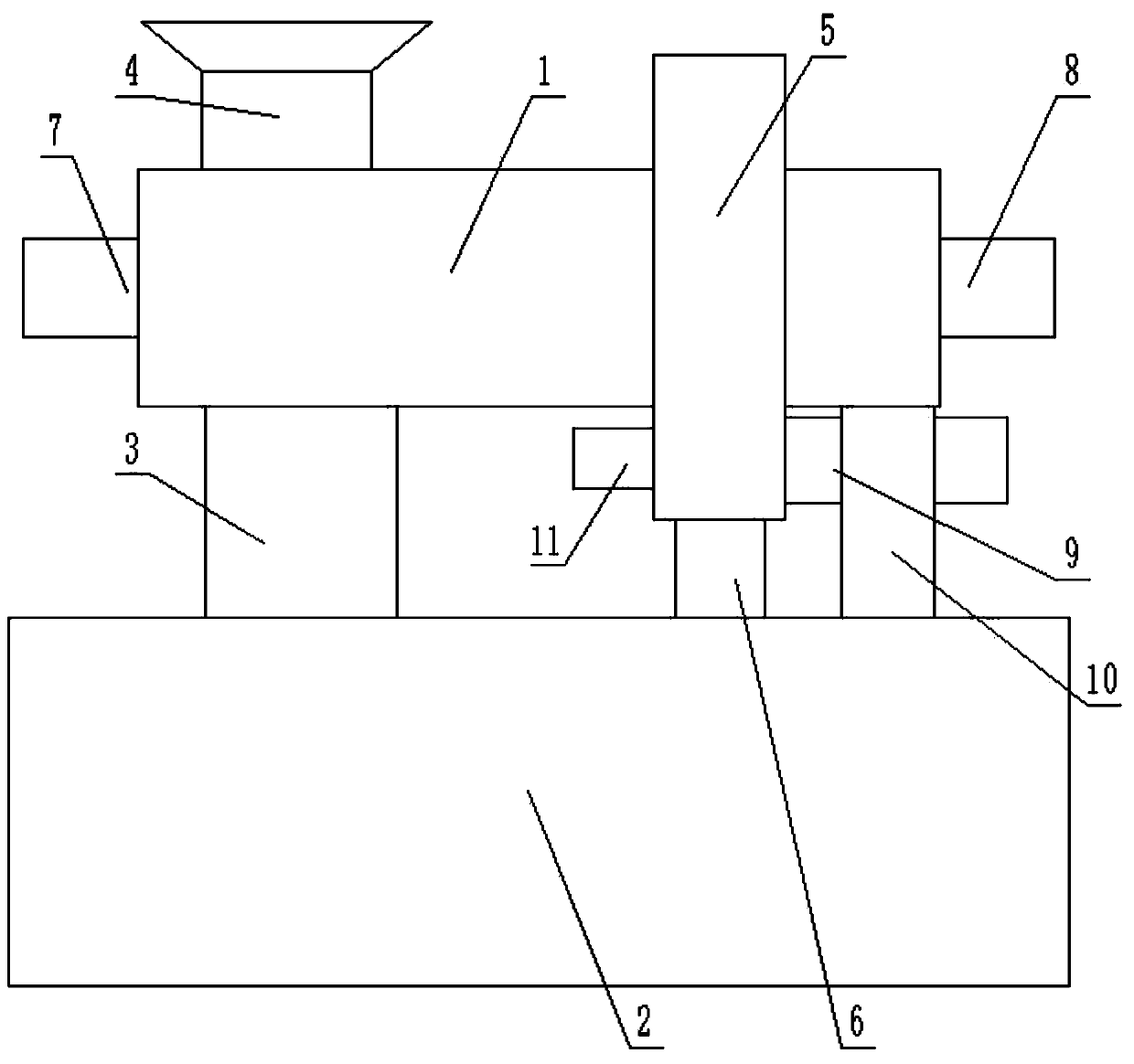

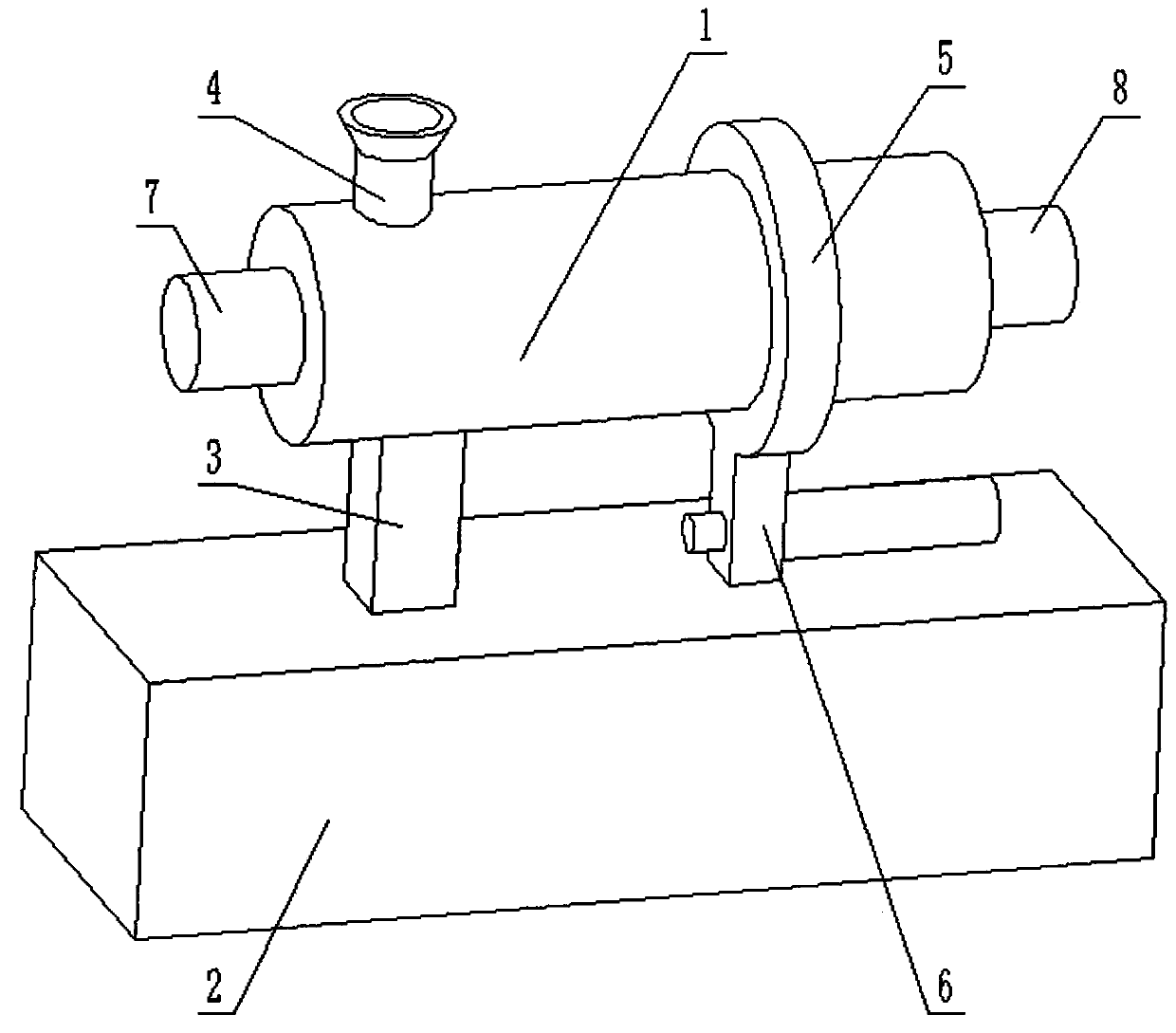

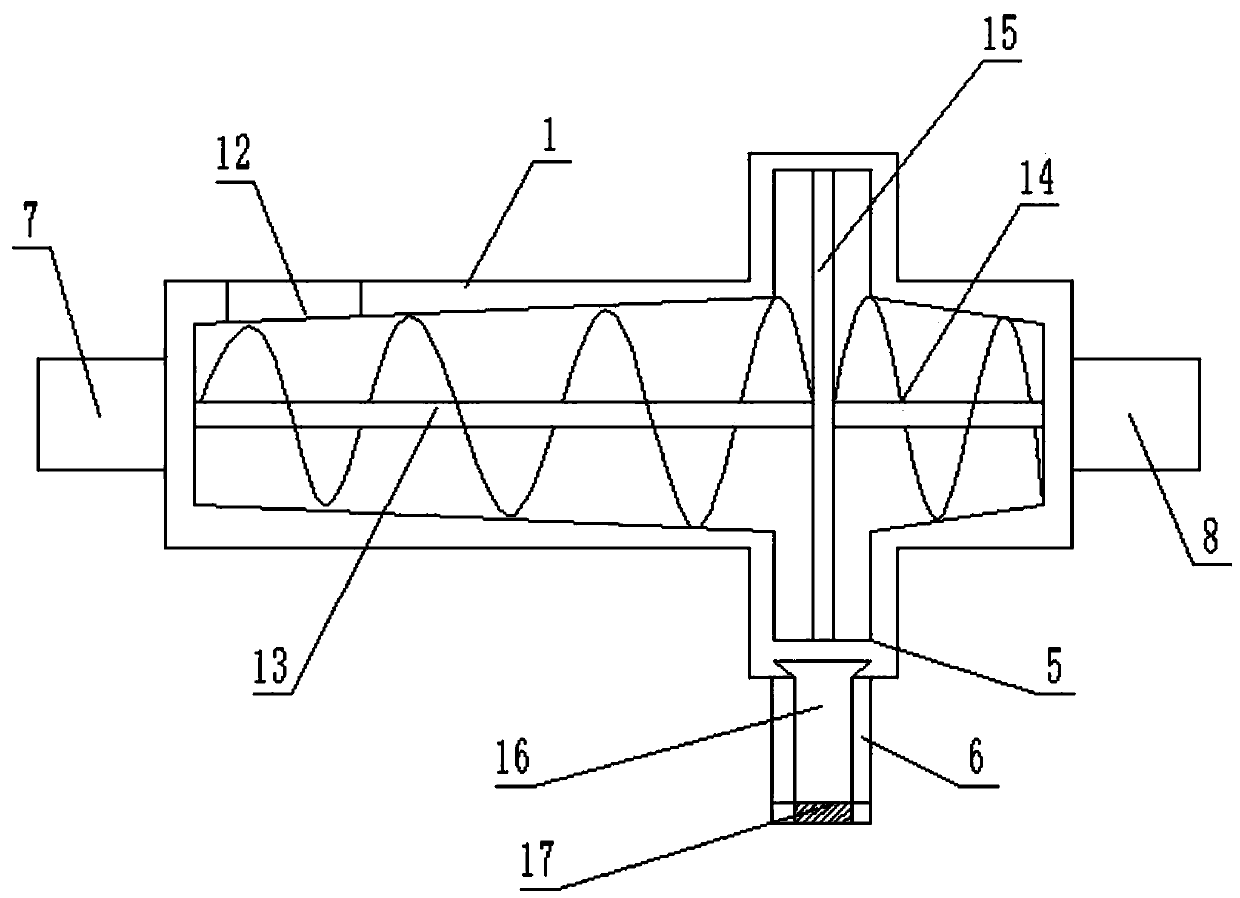

[0022] see Figure 1-3 , a two-way extrusion oily sludge treatment device, including a two-way extrusion cylinder 1 and a static layered box 2, the two-way extrusion cylinder 1 is fixed above the static layered box 2 and communicated with the static layered box 2 , between the two-way extrusion cylinder 1 and the static stratification box 2, a main support frame 3 and a secondary support frame 10 for supporting and fixing the two-way extrusion cylinder 1 are provided, and a feeding material is provided on the top of the two-way extrusion cylinder 1. The hopper 4 and the feed hopper 4 are used to transport the oily sludge into the two-way extrusion cylinder 1, and the two-way extrusion cylinder 1 is provided with an extrusion ring 5, and the inside of the extrusion ring 5 is connected with the inside of the two-way extrusion cylinder 1 In general, a vertical rod 15 is arranged in the extrusion ring 5, and a positive rotation auger 13 and a reverse rotation auger 14 are respecti...

Embodiment 2

[0028] refer to Figure 4 , on the basis of Embodiment 1, the mud outlet pipe 9 includes a cylindrical pipe body, which is arranged in a horizontal direction, and an output auger 18 coaxially arranged with it is provided in the cylindrical pipe body, and at the front end of the cylindrical pipe body An output motor 11 is provided, the output end of the output motor 11 is connected with the output auger 18, when the sludge is output, the drive motor is started to drive the output auger 18 to rotate, and the output auger 18 will filter the channel 16 The sludge inside is delivered to the tail of the mud outlet pipe 9, and when the sludge is output, the first drive motor 7 and the second drive motor 8 are started at the same time, so that the sludge in the two-way extrusion cylinder 1 is completely output.

[0029] Further, the tail end of the mud outlet pipe 9 is provided with a cover 19, and the cover 19 is threadedly connected with the cylindrical pipe body. When extruding, th...

Embodiment 3

[0031] refer to Figure 5, on the basis of Embodiment 1, a vertical partition 20 is provided in the static layered box 2, and the two sides of the partition 20 are respectively a static chamber 22 and a transfer chamber 23, and the screening channel 16 and The static chamber 22 is connected, and a communication port 21 is provided on the top of the partition plate 20. The communication port 21 is used to transfer the oil in the static chamber 22 to the transfer chamber 23, and a water supplement is inserted on the side wall of the static chamber 22. Pipe 24, water replenishing pipe 24 is used for adding water to the static cavity 22, when carrying out static stratification, because the density is different, the oil will float above the water, transfer in the transfer cavity 23 through the communication port 21, and when the liquid volume When it is less, water can be added to the static cavity 22 through the water supply pipe 24, thereby improving the liquid level position in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com