Treatment technology for preparing combustion gas by using biomass fixed-bed gasifier

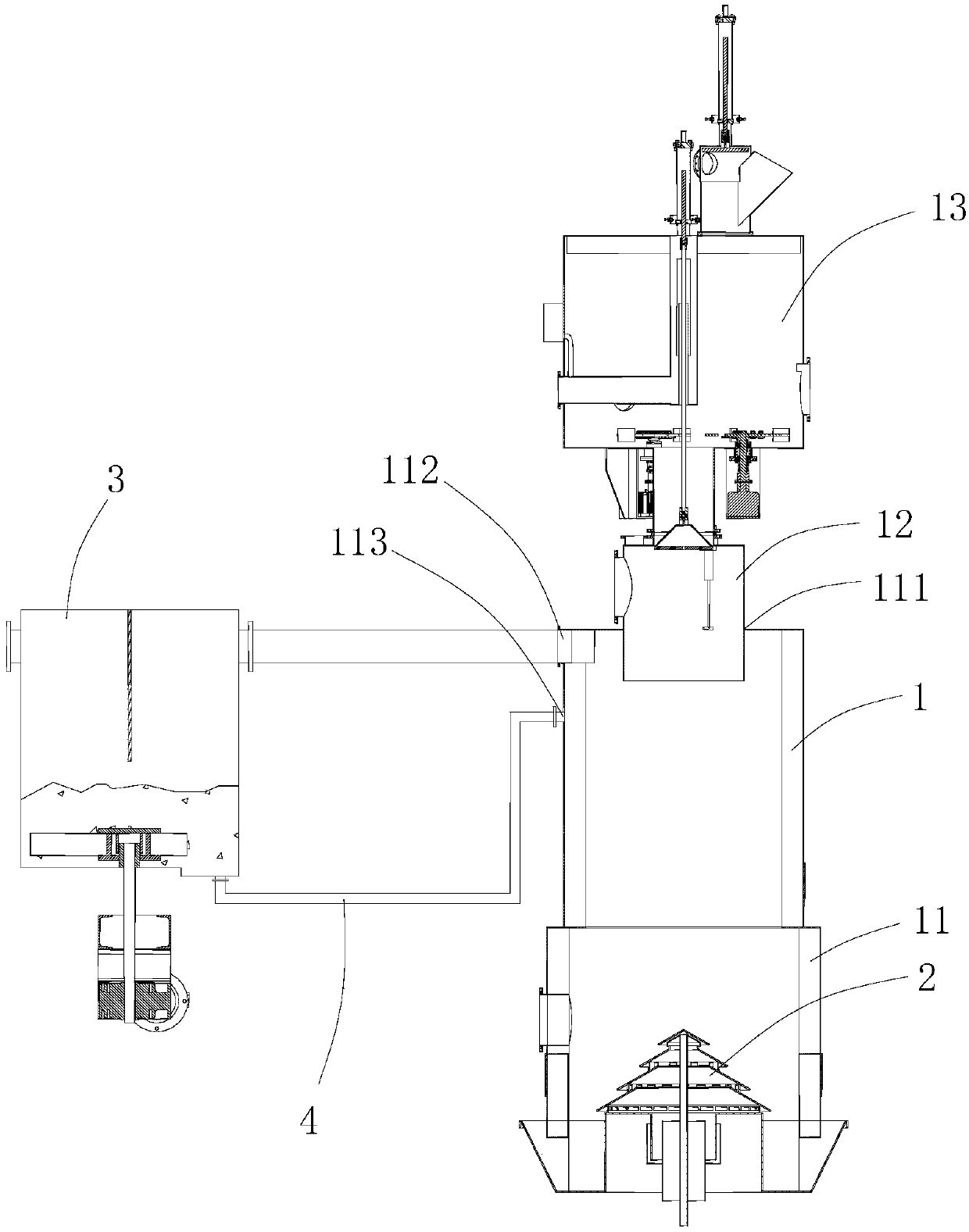

A fixed-bed gasifier and treatment process technology, applied in gasification process, combustible gas production, combustible gas purification, etc., can solve the problem that tar cannot be processed, and achieve good cooling effect, cost reduction, and large cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a treatment process for preparing fuel gas in a biomass fixed-bed gasifier, which includes:

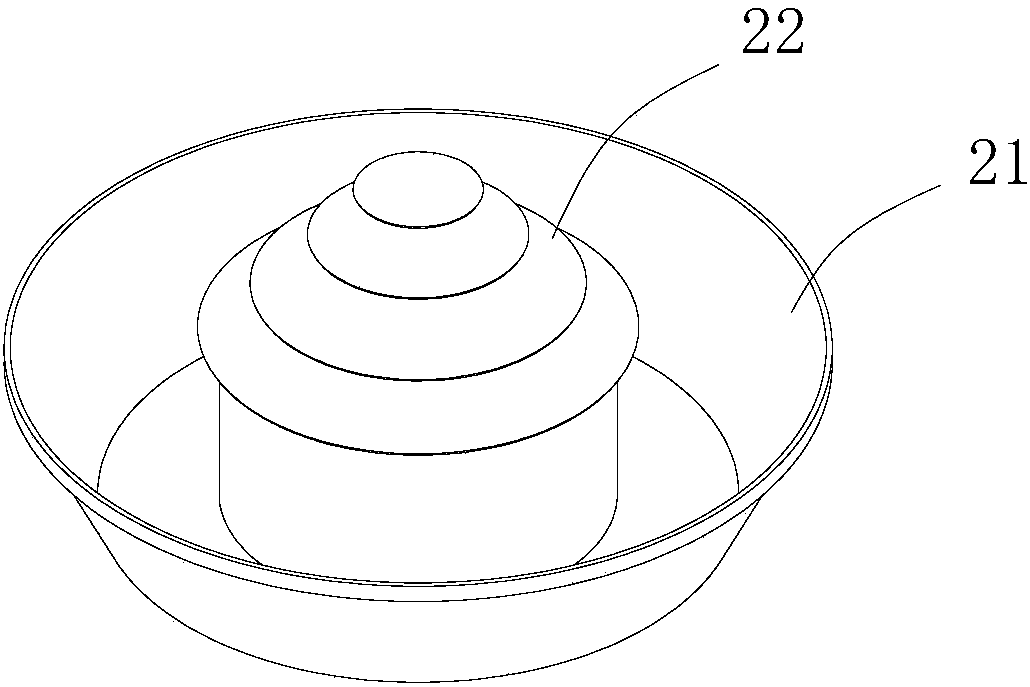

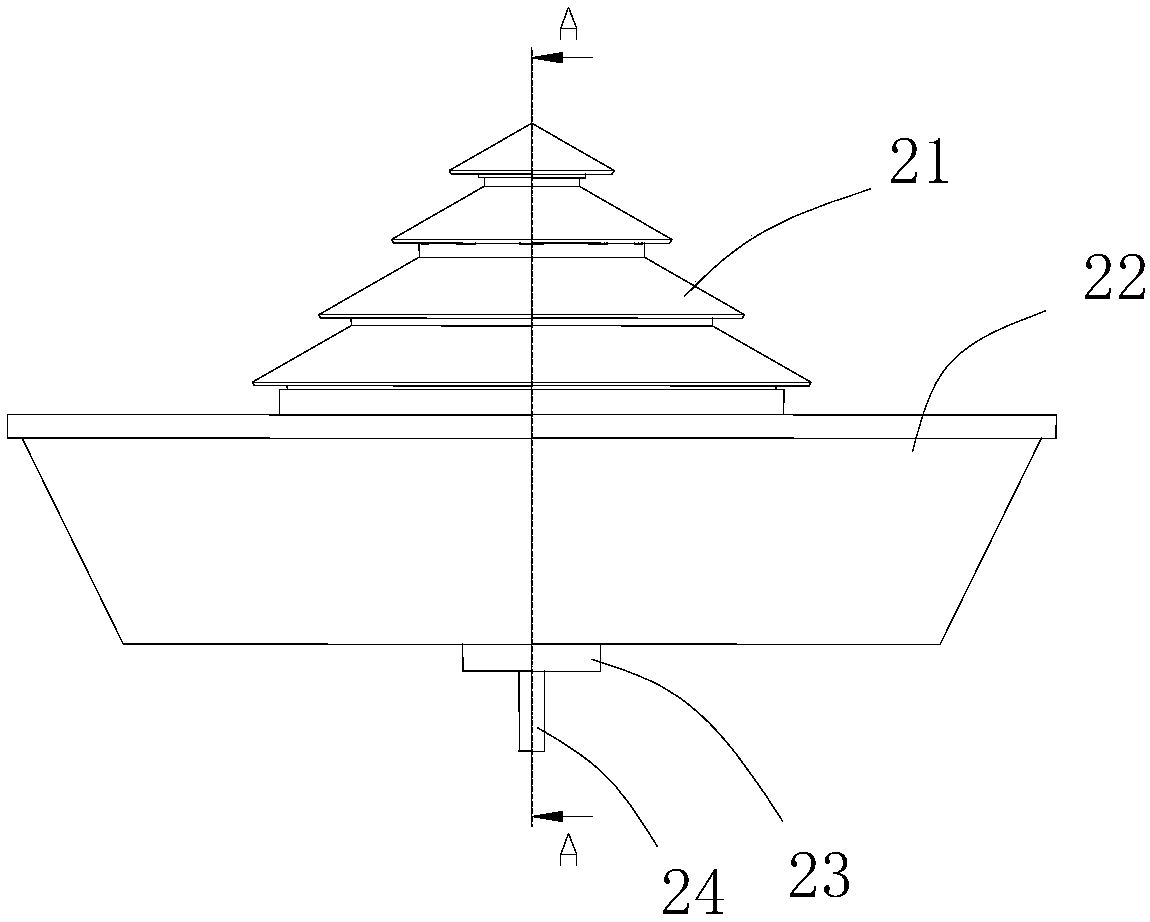

[0039] S1. Biomass raw materials are pyrolyzed and gasified in a fixed-bed gasifier to produce gas, and during the process of preparing gas, the grate is cooled by circulating water.

[0040]S2. Purify and remove dust from the gas: the gas enters from one end of the U-shaped gas channel, the temperature of the gas decreases, and the tar component contained in it condenses on the inner wall of the partition or the box, and at the same time captures the dust and tar accumulated in the gas After reaching a certain level, under the action of its own weight, it falls into the water at the bottom of the tank and is discharged from the discharge hole; the purified gas is discharged from the other end of the U-shaped gas channel.

[0041] S3. Put the tar in the gas purification device into the furnace body through the tar circulation pipeline for another reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com