A kind of purification method of ethylenic organic compound

A technology of organic compounds and purification methods, applied in the field of purification of organic compounds, can solve the problems of limited purification methods, few research reports, and high cost in the later stage, and achieve ideal impurity removal effects, mild process conditions, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

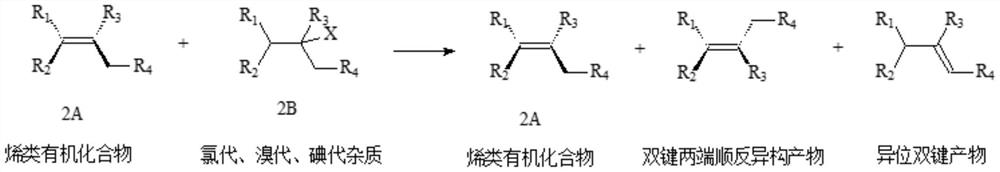

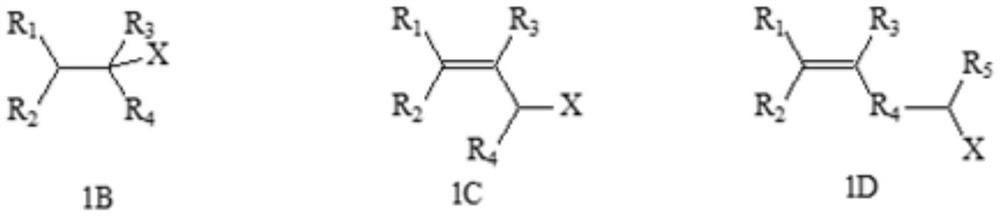

Problems solved by technology

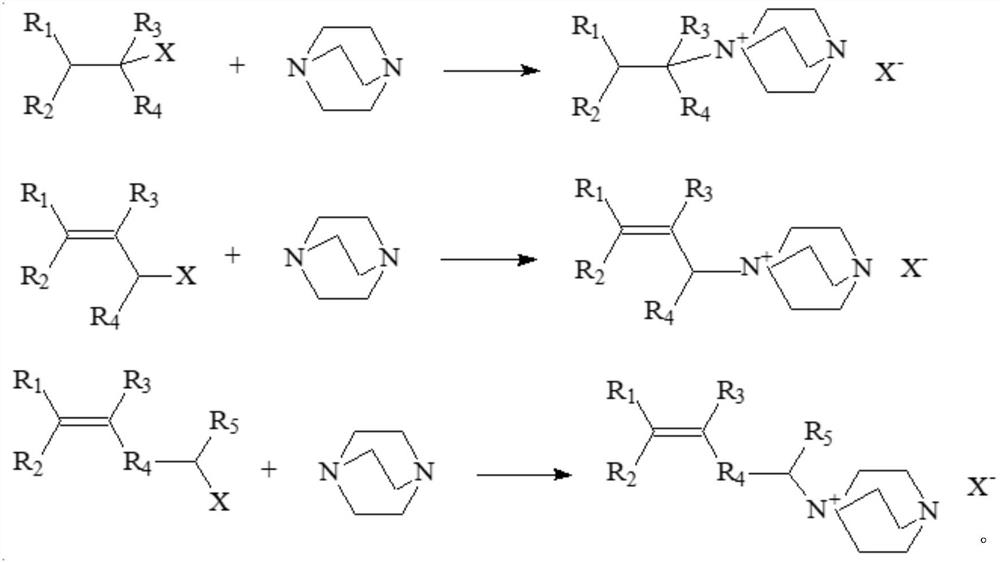

Method used

Image

Examples

Embodiment 1

[0049] At room temperature, 20 g of compound 2A (which contains about 1.5%, ie about 0.00075 mol of impurity compound 2B) was dissolved in 80 g of toluene; then 0.1 g (about 0.0009 mol) of triethylenediamine was added and stirred evenly. Then take out 10g from the 100g solution prepared above and put it into a special tubular microwave reaction container with a volume of 20ml, then put it into the microwave reactor, turn on the 100w microwave to carry out the catalytic reaction and time it; when the liquid temperature is close to 60°C , turn off the microwave immediately. Take out the reaction vessel, place it in a water bath at room temperature to cool down, until the liquid temperature in the tube drops to close to room temperature. Use 100w microwave again for catalytic reaction and timing. When the liquid temperature is close to 60°C, turn off the microwave again and take out the reaction vessel to cool down. This is repeated until the cumulative time for the catalytic re...

Embodiment 2

[0064] At room temperature, 100 g of compound 2A (which contains about 32 ppm, that is, about 8.2×10 -6 The impurity compound 2B of mol, the impurity compound 2D of 6ppm), be dissolved in the toluene of 400g; Then add 0.09g (approximately 8.2x10 -4 mol) of triethylenediamine, and stir evenly. Then take out 10g from the above prepared 500g solution, put it into a tubular microwave special reaction vessel with a volume of 20ml, then put it into the microwave reactor, turn on the 100w microwave to carry out the catalytic reaction and time it. When the liquid temperature is close to 60°C, turn off the microwave immediately. The reaction vessel was taken out and placed in a water bath at room temperature to cool down until the liquid temperature in the tube dropped to close to room temperature. Use 100w microwave again for catalytic reaction and timing, when the liquid temperature is close to 60°C, turn off the microwave again, take out the reaction vessel to cool down. This is ...

Embodiment 3

[0072] At room temperature, 100g of compound 3A (which contains about 61ppm, that is, about 1.6x10 -5 mol of impurity compound 3B), first dissolved in 1000g of n-heptane; then add 0.018g (about 1.6x10 -4mol) of triethylenediamine, and stir well. Pre-cool the above solution to 10-15°C, then use a peristaltic pump to transport it through a threaded glass coil, and then flow into the receiving bottle; the main body of the threaded glass coil is located in the microwave reactor, and is continuously irradiated by 300w microwave irradiated. Control the flow rate of the peristaltic pump so that the time for the solution to pass through the threaded glass coil is about 6 seconds; it can be measured that the temperature of the solution after passing through the coil rises to 15-20°C. At room temperature, pass the solution flowing out of the coil through a silica gel column filled with 20g of 60-100 mesh silica gel with a diameter-to-height ratio of less than 1:4 for adsorption and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com