Efficient crystallization and purification device and crystallization method for inorganic salt

An inorganic salt, high-temperature crystallization technology, applied in the field of chemical equipment, can solve the problems affecting the efficiency and cost of crystallization operation, surrounding environmental pollution, low heating efficiency, etc., to achieve flexible and convenient temperature adjustment operation, reduce energy consumption, and improve efficiency and quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

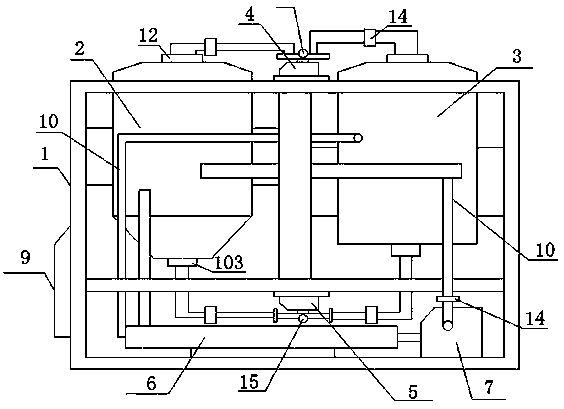

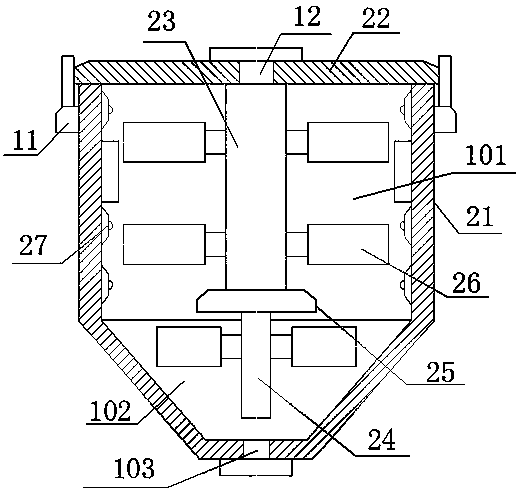

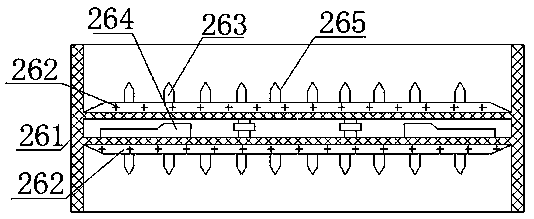

[0029] like figure 1 A high-efficiency crystallization and purification device for inorganic salts shown in —4 includes a load frame 1, a high-temperature crystallization kettle 2, a low-temperature crystallization kettle 3, a booster pump 4, a circulation pump 5, an air vortex tube 6, an air booster pump 7, and a The heater 8 and the drive circuit 9, the bearing frame 1 is a frame structure with the axis and the horizontal plane vertically distributed, at least one high-temperature crystallization kettle 2 and a low-temperature crystallization kettle 3 are embedded in the bearing frame 1 and surround the bearing frame 1 axis. The axes of the high-temperature crystallization kettle 2 and the low-temperature crystallization kettle 3 are distributed parallel to the axis of the bearing frame 1, and at least one heat exchanger 8 is arranged in the high-temperature crystallization kettle 2 and the low-temperature crystallization kettle 3, wherein the heat exchanger in the high-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com