Automatic cleaning device for sewage treatment plant floating-flow type secondary sedimentation tank effluent weir

A sewage treatment plant, automatic cleaning technology, applied in the feeding/discharging device of the sedimentation tank, sedimentation tank, sedimentation separation and other directions, can solve the problems of affecting the sewage treatment effect, consuming a large amount of labor, and slowing the cleaning speed, saving energy Labor intensity, high cleaning efficiency, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

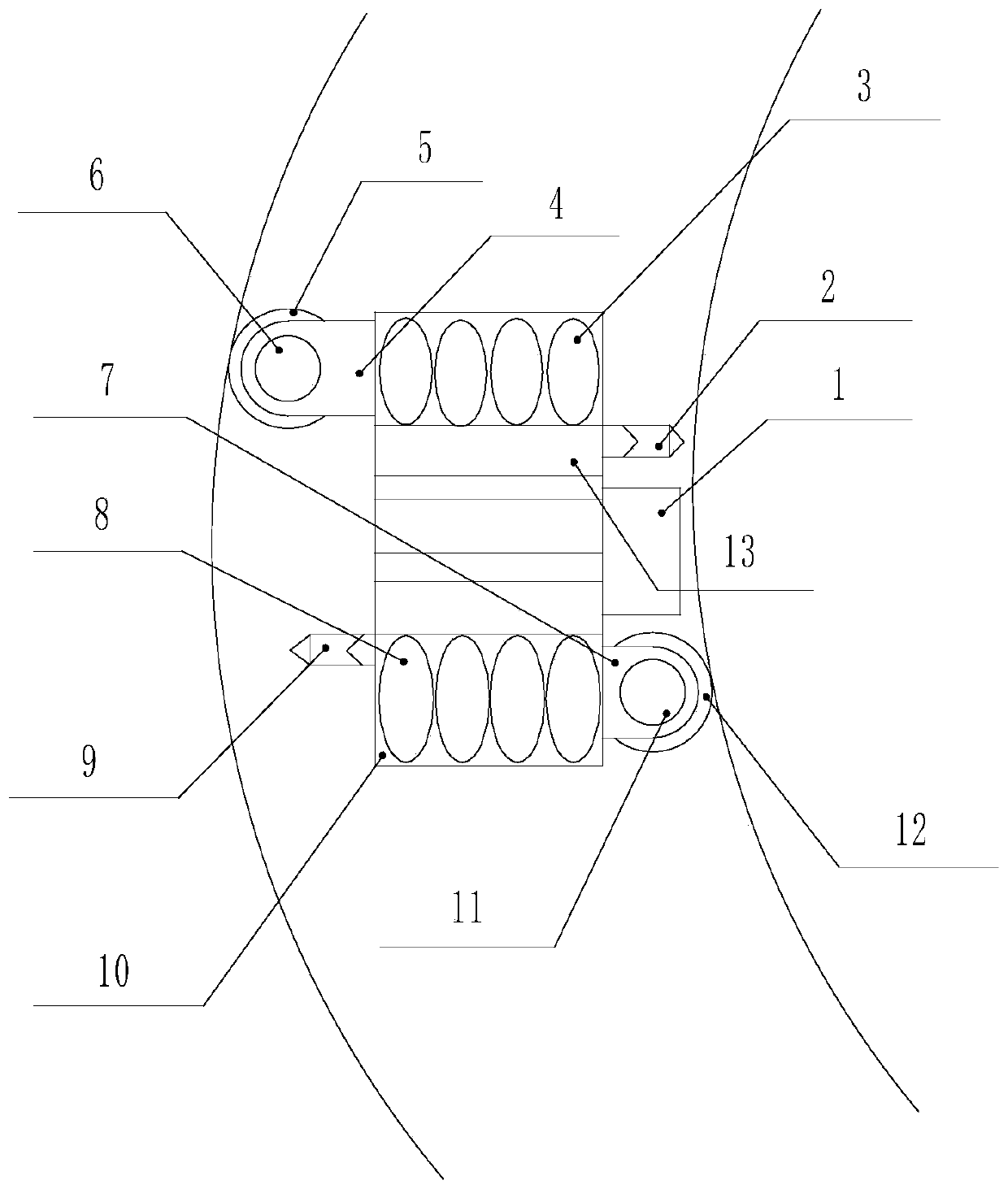

[0015] An automatic cleaning device for the outlet weir of a floating-flow secondary sedimentation tank in a sewage treatment plant, characterized in that it includes a slide table 1, a rear flushing nozzle 2, a first ultraviolet lamp tube 3, a front rotating arm 4, a front brush 5, and a front brush Motor 6, rear rotating arm 7, second ultraviolet lamp tube 8, front flushing nozzle 9, casing 10, rear brush motor 11, rear hair brush 12 and the third ultraviolet lamp tube 13, and described casing 10 is fixedly installed On the slide table 1, the first ultraviolet lamp tube 3 is fixedly installed in the installation hole on the right side of the casing 10 and the first ultraviolet lamp tube 3 is installed vertically, and the rear flushing nozzle 2 is fixed Installed in the mounting hole on the rear side of the casing 10, the front arm 4 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com