Magnesium alloy mining device

A magnesium alloy and mining technology, applied in spraying devices, spray booths, etc., can solve the problems of wasting manpower, unqualified performance, surface pollution, etc., and achieve the effect of saving space, improving efficiency, and convenient control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

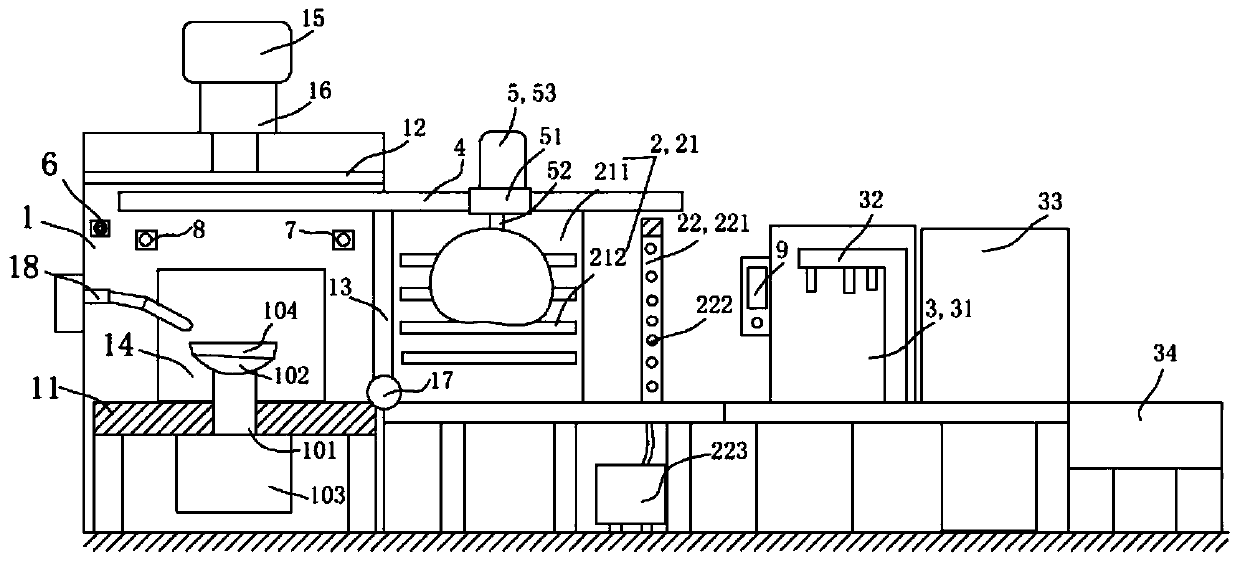

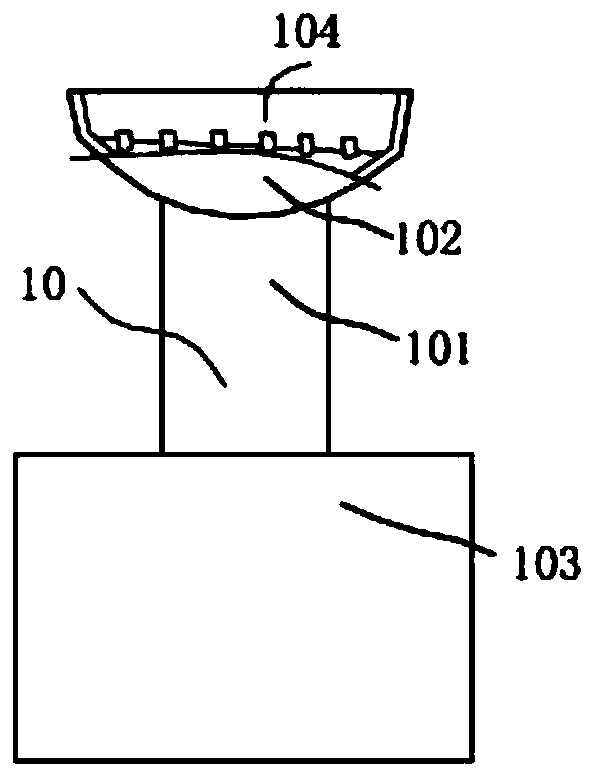

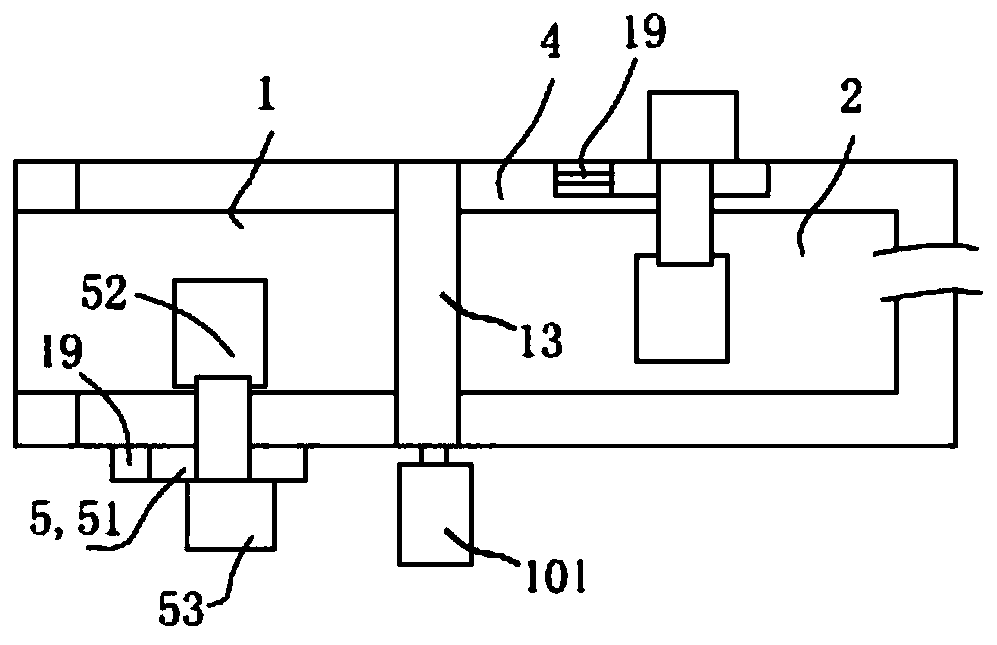

[0021] Such as figure 1 As shown, the magnesium alloy mining device includes a paint spraying room 1, a curing and drying station 2, and a grinding station 3 connected in sequence, and a hanging channel is provided on the side of the paint spraying room 1 and the curing and drying station 2 near the top. 4. The magnesium alloy is connected to the hanging channel 4 through the walking hanging device 5 and hangs continuously in the hanging channel 4 to complete painting, curing and drying; where: the painting room 1 includes a disc-shaped painting base 11, a telescopic pressure top plate 12, and an externally drawn Side sealing door 13 and feed airtight door 14, painting mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com