Acidic veneer dyeing material, and preparation method and dyeing process thereof

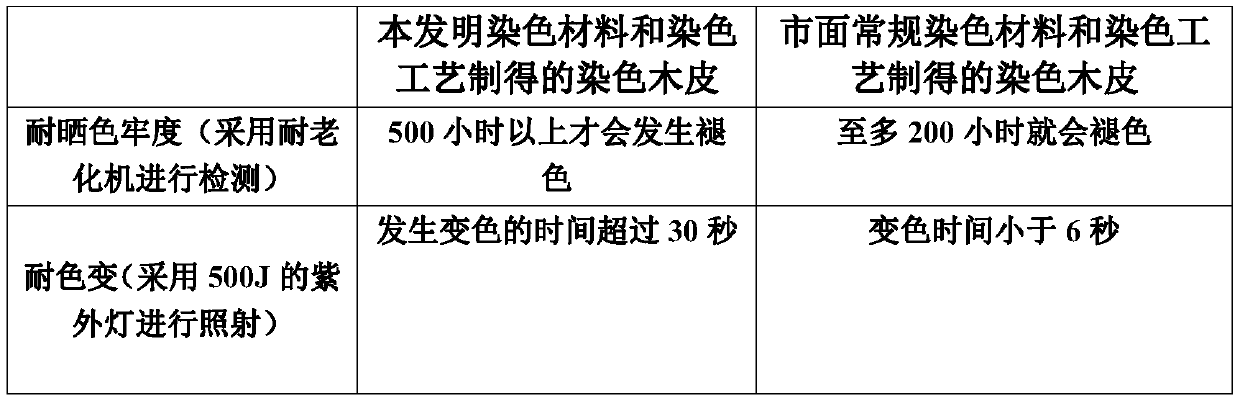

A veneer and acidic technology, which is applied in the field of dyeing materials, can solve the problems of affecting the aesthetic effect of wood products, poor wear resistance of the surface of dyed veneer, and easy scratches on the surface of dyed veneer, so as to improve the dyeing speed and efficiency, and enhance the color. Fastness, the effect of improving color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1. An acidic wood veneer dyeing material, comprising the following components by weight: anionic aliphatic polyurethane dispersion, 10-15 parts; water-based acrylic resin, 4-6 parts; acid dye, 35-40 parts; twelve Alkyltrimethylammonium chloride, 0.5-0.8 parts; Hexadecyltributylammonium ammonium halide, 0.9-1.2 parts; C 6-20 Alkyl fatty alcohol, 1.5-1.8 parts; C 4-12 Alkylphenol, 0.3-0.6 parts; naphthalene sulfonic acid formaldehyde polycondensate, 8-11 parts; isooctyl alcohol polyoxyethylene ether sulfate, 0.6-1.0 parts; blocked water-based isocyanate crosslinking agent, 4.5-5.5 parts; Dispersed porous polymer microspheres, 1.2-1.6 parts; hard water, 18-22 parts.

[0033] Hard water refers to water of 2.0-10.5 GPG; GPG is the unit of water hardness, and 1 GPG means that the content of hardness ions (calcium and magnesium ions) in 1 gallon of water is 1 grain.

[0034] The acid dye can be selected from one of strong acid dye, weak acid dye, acid mordant dye, aci...

Embodiment 2

[0051] Example 2. A kind of acid veneer staining material, comprises the component of following parts by weight to make: anionic type aliphatic polyurethane dispersion, 12 parts; Waterborne acrylic resin, 5 parts; Acid dyestuff, 38 parts; Dodecyltrimethylammonium chloride, 0.6 parts; Hexadecyltributylammonium halide, 1.1 parts; C 6-20 Alkyl fatty alcohol, 1.6 parts; C4-12 alkylphenol, 0.5 parts; naphthalene sulfonic acid formaldehyde polycondensate, 9 parts; isooctyl alcohol polyoxyethylene ether sulfate, 0.8 parts; blocked water-based isocyanate crosslinking agent, 5 parts parts; monodisperse porous polymer microspheres, 1.4 parts; hard water, 20 parts.

[0052] The acid dye can be selected from one of strong acid dye, weak acid dye, acid mordant dye, acid complex dye or acid powder toner.

[0053] A kind of preparation technology of acid veneer dyeing material, comprises the following steps:

[0054] A. Mix the anionic aliphatic polyurethane dispersion with the water-base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com