Pressure-equalization energy recovery system for blast-furnace hot-blast stoves, and use method of system

A technology of energy recovery and hot blast stove, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems affecting blast furnace production, energy waste, and large fluctuations in cold air pressure, achieving good economic and social effects and reducing costs , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

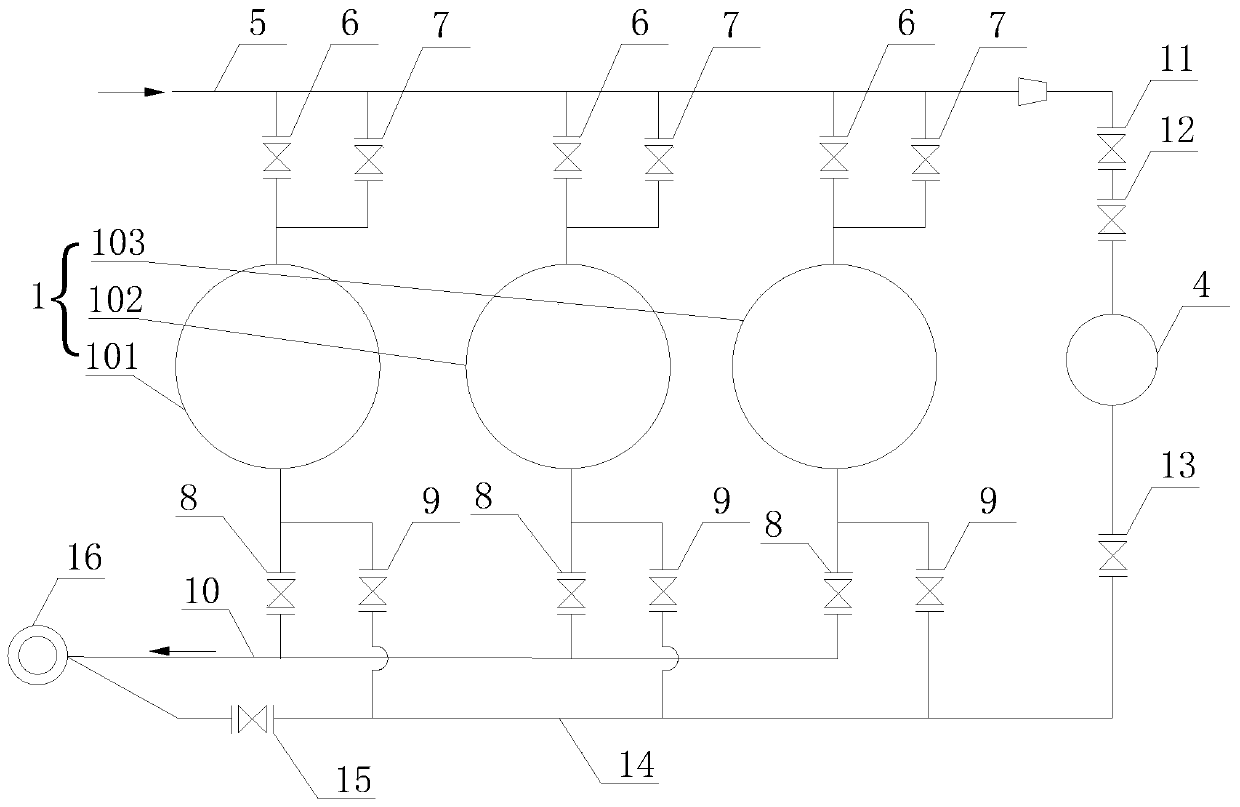

[0024] The present invention is a pressure equalization energy recovery system for blast furnace hot blast stoves, which includes several hot blast stoves 1, residual pressure recovery tanks 4, cold air pipes 5, flue gas pipes 10, pressure discharge pipes 14 and chimneys 16; several hot blast stoves 1 A cold air cut-off valve 6 and a cold air pressure equalizing valve 7 are arranged in parallel between the inlet of the cold air pipe 5 and the pipe, and a smoke cut-off valve 8 is arranged between the outlet and the flue gas pipe 10 through pipes, and the outlet and the exhaust pressure A cold air pressure relief valve 9 is arranged through a pipeline between the pipes 14; a pressure regulating valve 11 and a pressure filling valve 12 are arranged through a pipeline between the inlet of the residual pressure recovery tank 4 and the cold air pipeline 5, and the outlet and the pressure relief valve 12 are arranged through the pipeline. A pre-pressure equalization valve 13 is provid...

Embodiment 2

[0030]A method for using a pressure equalizing energy recovery system for blast furnace hot blast stoves described in Embodiment 1, one of the several hot blast stoves 1 is in the air supply state, and the other hot blast stoves 1 are in the firing state; the hot blast in the air supply state The furnace 1 is in a high-pressure state, the cold air cut-off valve 6 and the cold air pressure equalizing valve 7 at its inlet are respectively open and closed, the flue gas cut-off valve 8 and the cold air pressure relief valve 9 at its outlet are both in a closed state, and the high-pressure cold air passes through The cold blast pipe 5 and the cold blast cut-off valve 6 enter the hot blast stove 1 to be heated and then sent to the blast furnace for utilization; In the closed state, the cold air pressure relief valve 9 and the flue gas cut-off valve 8 at the outlet are respectively in the closed and open states, and the flue gas produced by the combustion of these hot blast stoves 1 i...

Embodiment 3

[0037] Such as figure 1 As shown, a kind of pressure equalization energy recovery system for blast furnace hot blast stove of the present invention is characterized in that it includes several hot blast stoves 1, residual pressure recovery tank 4, cold air pipeline 5, flue gas pipeline 10, pressure discharge pipe 14 and chimney 16; This embodiment takes three hot blast stoves 1 as an example for illustration, these three hot blast stoves are No. 1 hot blast stove 101, No. 2 hot blast stove 102 and No. 3 hot blast stove 103; Between the inlet of No. hot blast stove 102 and No. three hot blast stove 103 and the cold wind pipeline 5, a cold wind cut-off valve 6 and a cold wind equalizing valve 7 are arranged in parallel through pipelines. The outlet of No. hot blast stove 103 and the flue gas pipeline 10 are all provided with a flue gas shut-off valve 8 through the pipeline, and the outlets of the No. 1 hot blast stove 101, No. A cold air pressure relief valve 9 is provided thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com