Weathering resistant steel and steel plate and angle steel manufacture methods by adopting weathering resistant steel

A technology of weathering steel and angle steel, applied in the field of weathering steel and its steel plate production, angle steel production, can solve the problems of atmospheric and soil environmental pollution, frequent and complicated maintenance process, complicated and time-consuming processing process, etc., and achieve mechanical and anti-corrosion performance improvement, obvious Economic benefits and environmental protection, the effect of reducing anti-corrosion maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

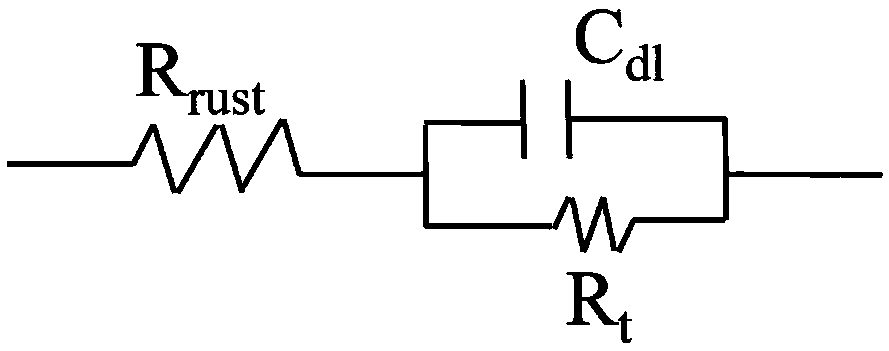

Image

Examples

Embodiment 1

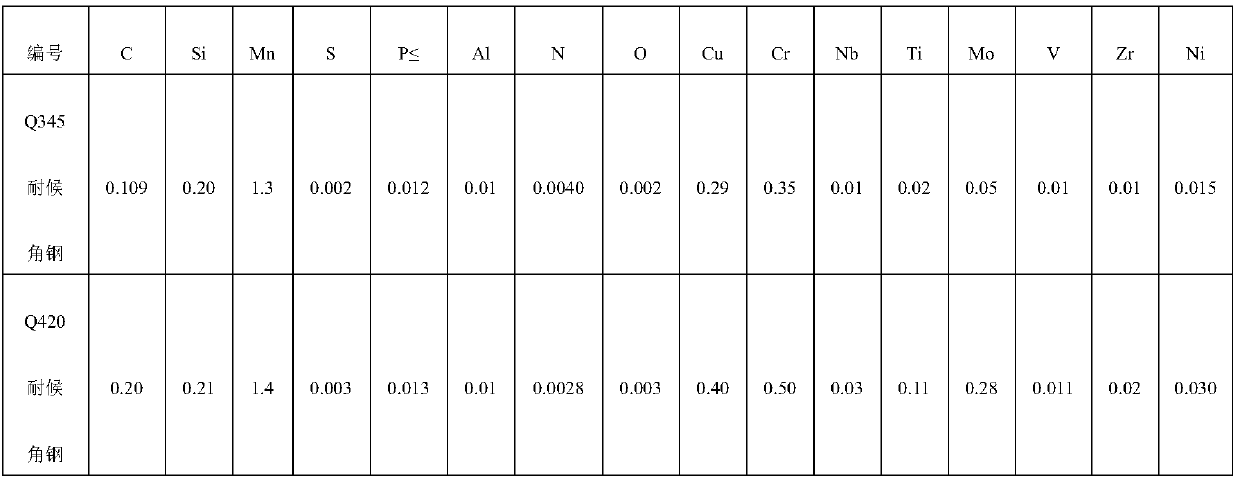

[0038] This example provides two kinds of weathering steels, namely Q345 weathering angle steel and Q420 weathering angle steel, which respectively contain Fe and unavoidable impurities, and see Table 1 for the remaining components.

[0039] Table 1 Chemical composition list (wt%) of two kinds of weathering steel angle steels

[0040]

[0041] The tensile, impact and bending mechanical properties of the above two weather-resistant angle steels provided in this example were tested respectively, and the results are shown in Table 2.

[0042] Table 2: Test results of mechanical properties of two weathering steels

[0043]

[0044] It can be seen from the above table that the tensile, impact and bending mechanical properties of Q345 weather-resistant angle steel and Q420 weather-resistant angle steel are very excellent, which have been significantly improved compared with the existing angle steel.

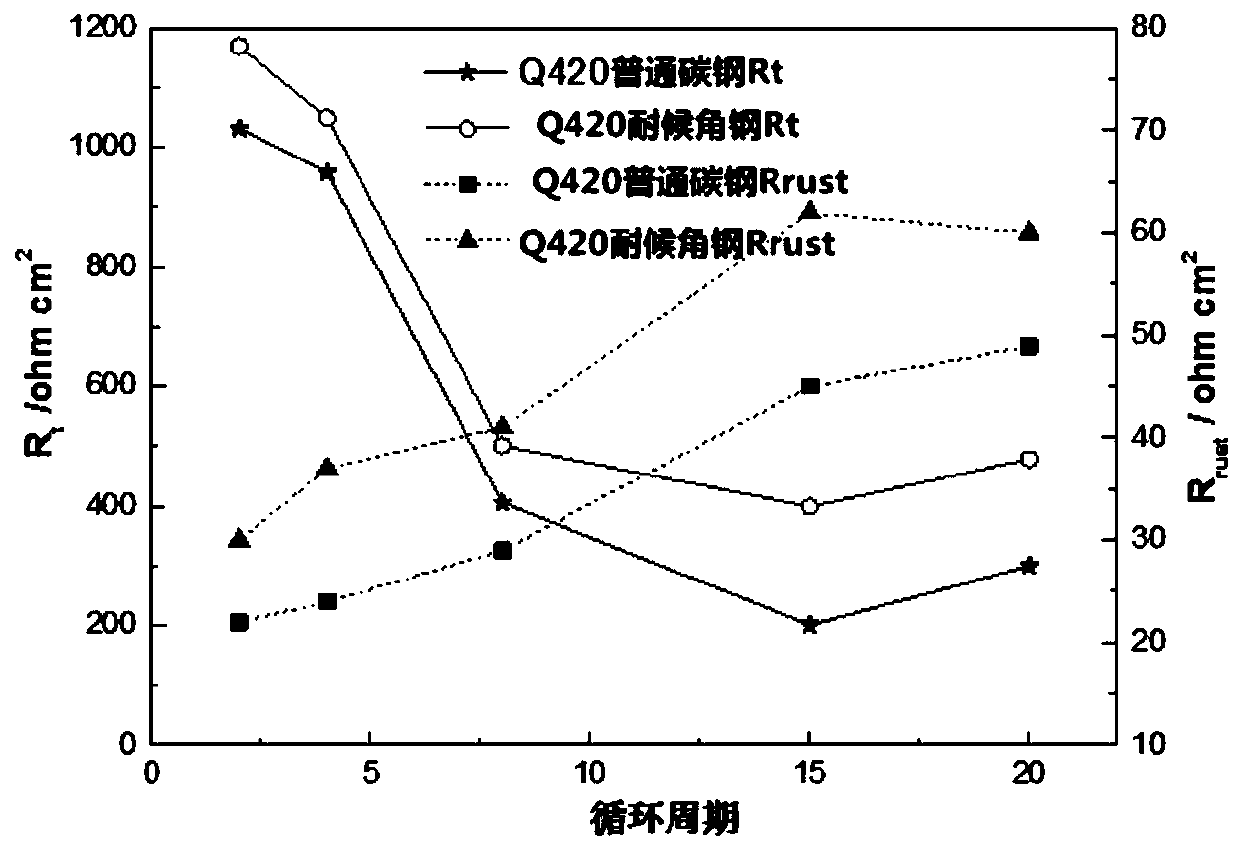

[0045] The Q420 weather-resistant angle steel and the Q420 ordinary carbon ...

Embodiment 2

[0048] Based on the same inventive concept, the present invention also provides a steel plate forming method of the above-mentioned weathering steel, the method comprising the following steps:

[0049] (1) LF refining and RH vacuum treatment and continuous casting are carried out successively after the weathering steel molten steel is smelted in a converter or an electric furnace;

[0050] (2) Roughly rolling the billet after continuous casting to 9 to 15 times the thickness of the finished product and finish rolling at 1200-1300°C according to the time requirement of 1.5min / mm; the entrance temperature of the finish rolling is 980-620°C, The final rolling temperature is 890-900°C;

[0051] (3) The steel plate after finish rolling is laminarly cooled according to the front cooling mode and coiled into coils at 580-620 ° C, and then kept for 1 hour after coiling and then air-cooled.

Embodiment 3

[0053]Based on the same inventive concept, the present invention also provides a method for forming an angle steel of the above-mentioned weathering steel, the method comprising the following steps:

[0054] (1) LF refining and RH vacuum treatment and continuous casting are carried out successively after the weathering steel molten steel is smelted in a converter or an electric furnace;

[0055] (2) Heat the billet after continuous casting at 1200-1300°C for 1.5 min / mm and then carry out rough rolling and profile rolling in sequence.

[0056] The profile rolling adopts 4 butterfly pass rolling mills with vertical rolling to carry out 4 rolling, and the 4 rolling mills are respectively BD1, BD2, F1, F2;

[0057] The BD2 and F1 use a common guide;

[0058] The F2 entrance adopts a rolling guide, and the rolling guide includes a total of three guide wheels, one up and two down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com