Treatment method capable of improving surface hardness of tungsten and molybdenum serial high speed steel

A surface hardness and treatment method technology, applied in surface hardness treatment, can improve the surface hardness treatment field of tungsten-molybdenum high-speed steel, can solve problems such as technology without surface hardness, heat treatment method without surface hardness, etc., to improve surface hardness and Abrasion resistance and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Carry out quenching treatment to high-speed steel W9Mo3Cr4V:

[0023] Measure the surface hardness of high-speed steel W9Mo3Cr4V after quenching according to GB9943-88:

[0024] Table 1 Quenching process parameters

[0025]

[0026] All samples after quenching and tempering are tested for hardness with a load of 60 kg, and each sample is tested at 3 points, and the average value is HRC65-66 (822-850HV).

[0027] The structure of the sample after quenching was observed with 4% nitric acid alcohol solution. The structure was quenched martensite + granular carbide, the grain size was relatively uniform, and the grade of eutectic carbide was 2. Because the quenched martensite is not easy to corrode, the martensite structure is not obvious, such as figure 1 shown. Depend on figure 1 It can be seen that there is no obvious retained austenite, which is because the retained austenite is reduced to the minimum value after two temperings.

Embodiment 2

[0028] Embodiment two: the high-speed steel W9Mo3Cr4V after quenching is carried out gas nitriding research by the method shown in table 2:

[0029] Table 2 Gas nitriding process

[0030]

[0031] After studying different nitriding methods, it is finally believed that the process parameters of one-stage pure ammonia nitriding and nitriding temperature of 510°C±5°C are the best, and the hardness of the nitriding surface is also the best.

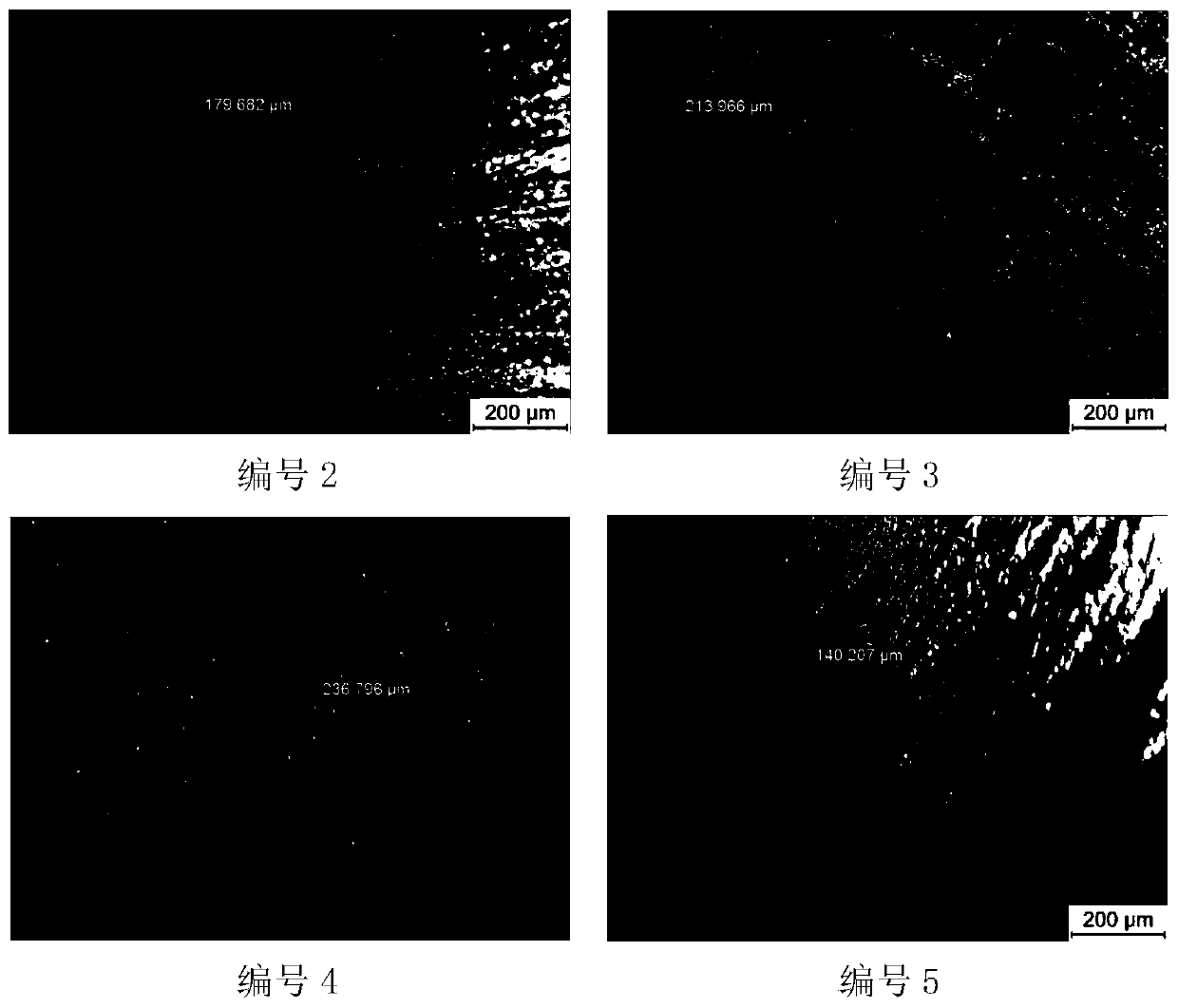

[0032] figure 2 It is the infiltrated layer structure of different test numbers, it can be seen that the infiltrated layer basically has no white bright layer after nitriding. After being corroded by nitric acid alcohol, the nitrided layer becomes dark and gradually transitions to the central bright area. The transition degree can only be seen by the color under the optical microscope, and there is no organizational change.

[0033] After the quenched high-speed steel W9Mo3Cr4V undergoes gas nitriding, the surface layer has high hardnes...

Embodiment 3

[0035] The surface hardness of the nitrided high-speed steel W9Mo3Cr4V is further improved by ice-cooling treatment.

[0036] The high-speed steel W9Mo3Cr4V after quenching and gas nitriding was divided into two groups, one group was subjected to ice-cooling treatment, the temperature was ≤-75°C, kept for 1-1.5 hours, and air-cooled; the other group was not subjected to ice-cooling treatment, which was used as a control.

[0037] Using 500g load to check the hardness of the nitrided layer after ice-cold treatment is 1054HV0.5, and the brittleness is grade II. The ice-cold treatment greatly improves the surface hardness of high-speed steel W9Mo3Cr4V after nitriding.

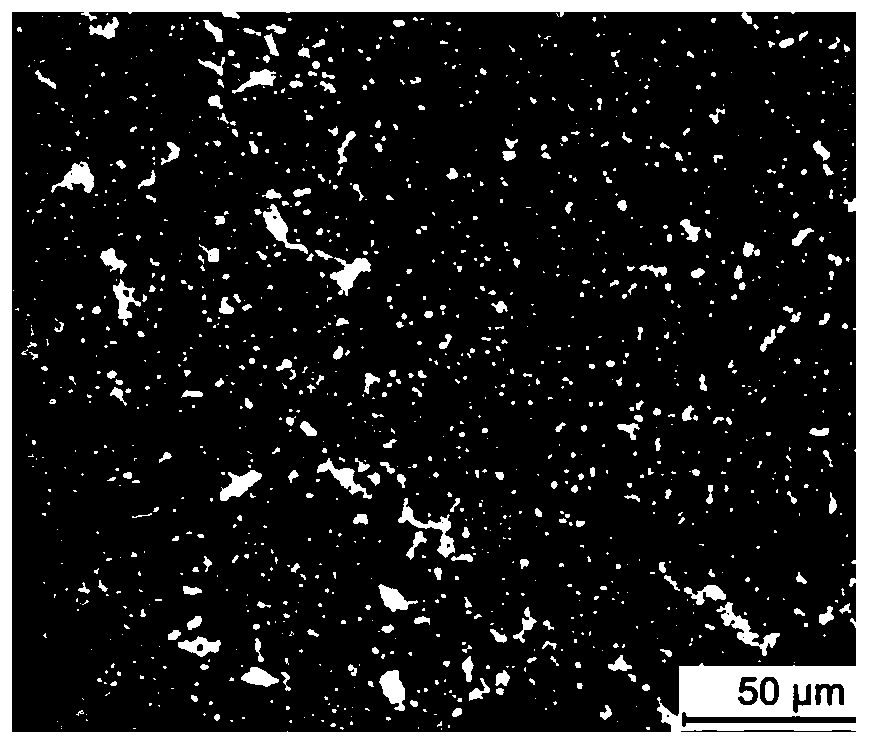

[0038] After the two groups of samples were corroded with 4% ferric chloride solution, their structures were observed under a 500 times optical microscope, as shown in image 3 , Figure 4 , Figure 5 as well as Image 6 shown. Depend on image 3 as well as Figure 4 It can be seen from the figure that after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com