Material drying unit

A material and unit technology, applied in the direction of dryers, drying, progressive dryers, etc., can solve the problems of low drying efficiency, achieve long drying time, ensure sufficient drying, and adapt to temperature changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

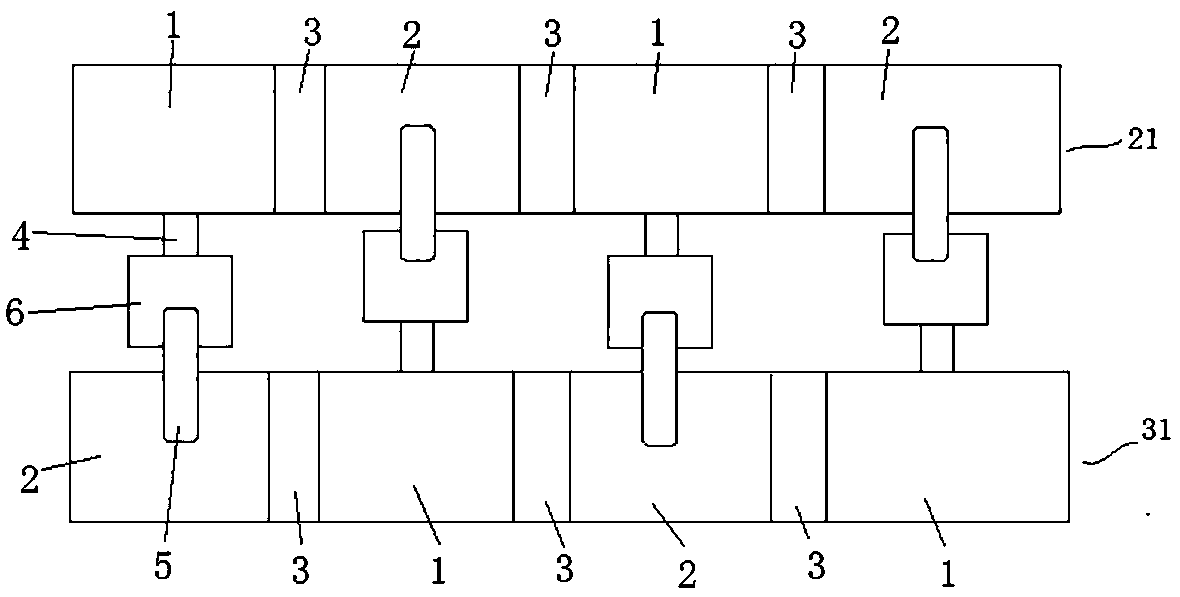

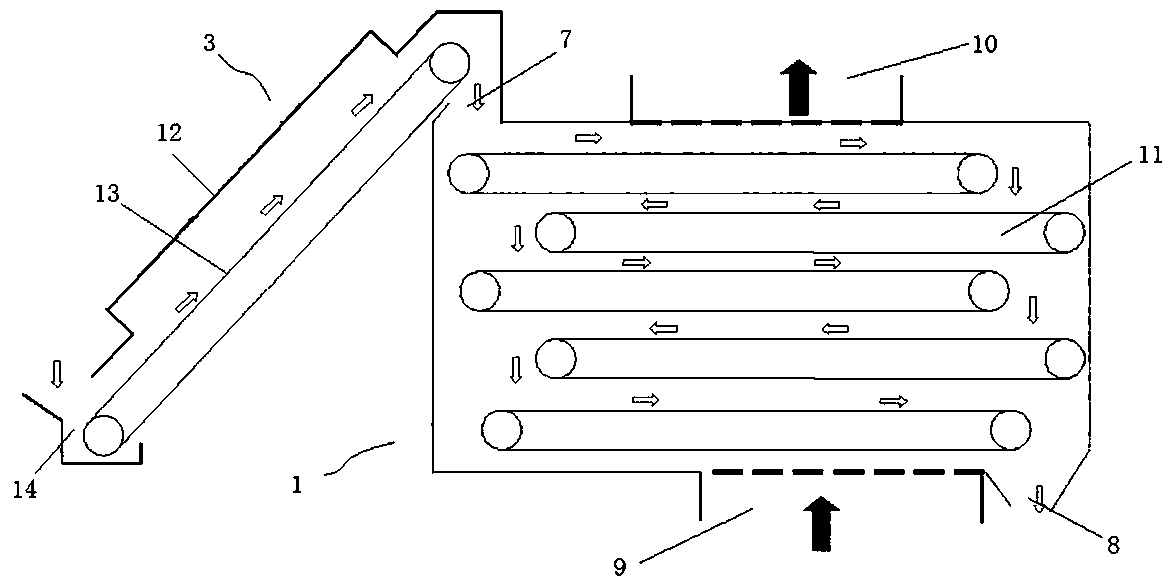

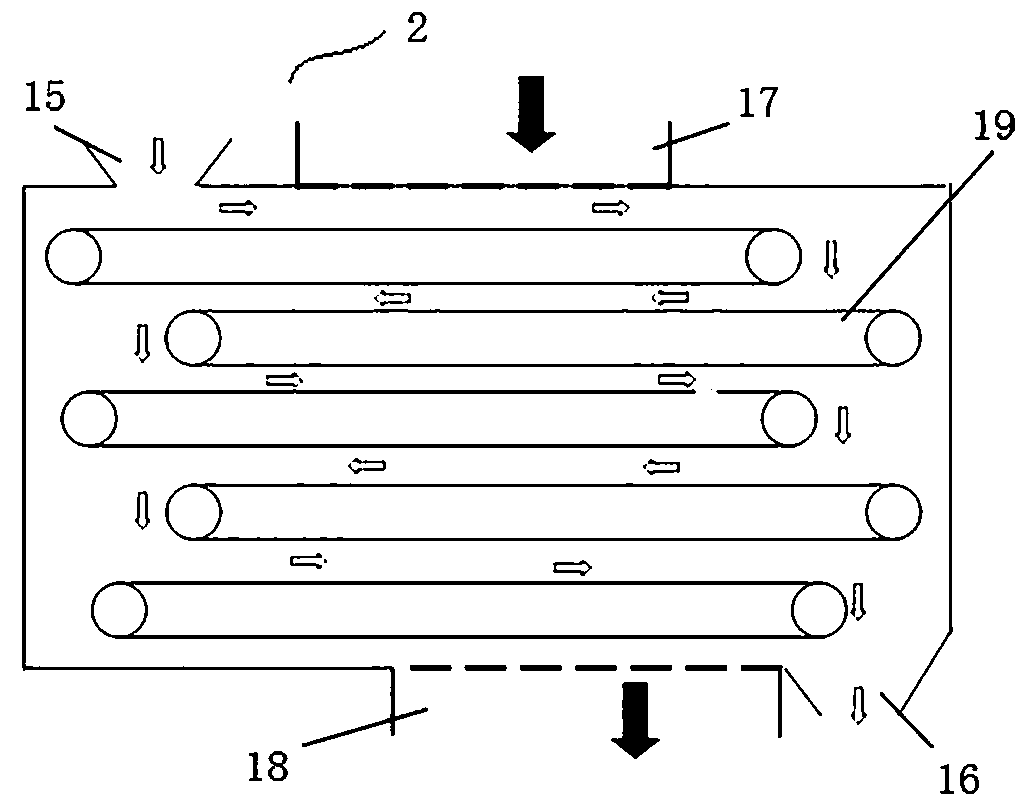

[0035] Such as figure 1 As shown, the material drying unit includes a hot air drying area 1 and a cold air drying area 2. The hot air drying area 1 dries the material through the hot air, and the cold air drying area 2 dries the material through the cold air. The hot air drying area 1 and the cold air drying area 2 are both There are more than two places, the hot air drying area 1 and the cold air drying area 2 are alternately arranged for the materials to be dried to pass through the hot air drying area 1 and the cold air drying area 2 alternately.

[0036] In this embodiment, an isolation area 3 is provided between the hot air drying area 1 and the cold air drying area 2, so as to avoid mutual influence between the hot air drying area 1 and the cold air drying area 2, and also to facilitate material transportation.

[0037] Such as figure 1 As shown, the material drying unit includes two drying lines, which are respectively the first drying line 21 and the second drying lin...

Embodiment 2

[0048] Such as Figure 4 As shown, the difference from Example 1 is that the material drying unit is in the form of a single line, and an adjacent cold air drying area 102 and a hot air drying area 101 form a group of drying areas, and a group of drying areas corresponds to a heat pump 106, the hot end 104 of the heat pump 106 corresponds to the hot air drying area 101 of the group of drying areas, and the cold end 105 corresponds to the cold air drying area 102 of the group of drying areas. Wherein, an isolation area 103 is provided between the adjacent cold air drying area 102 and the hot air drying area 101 .

Embodiment 3

[0050] The difference from Embodiment 1 is that the cold end of a heat pump corresponds to more than two cold air drying areas, and at this time, more than two pipelines need to be drawn from the cold end to correspond to each cold air drying area; or the cold end of a heat pump The hot end corresponds to more than two hot air drying areas. At this time, the hot end needs to lead out more than two pipelines to correspond to each hot air drying area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com