Drying waste heat reutilizing integration device

A waste gas and dryer technology, applied in heating devices, drying, dryers, etc., can solve the problems of imperfect heat recovery equipment, less heat recovery, environmental pollution, etc., to achieve good environmental protection, high degree of automation, application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

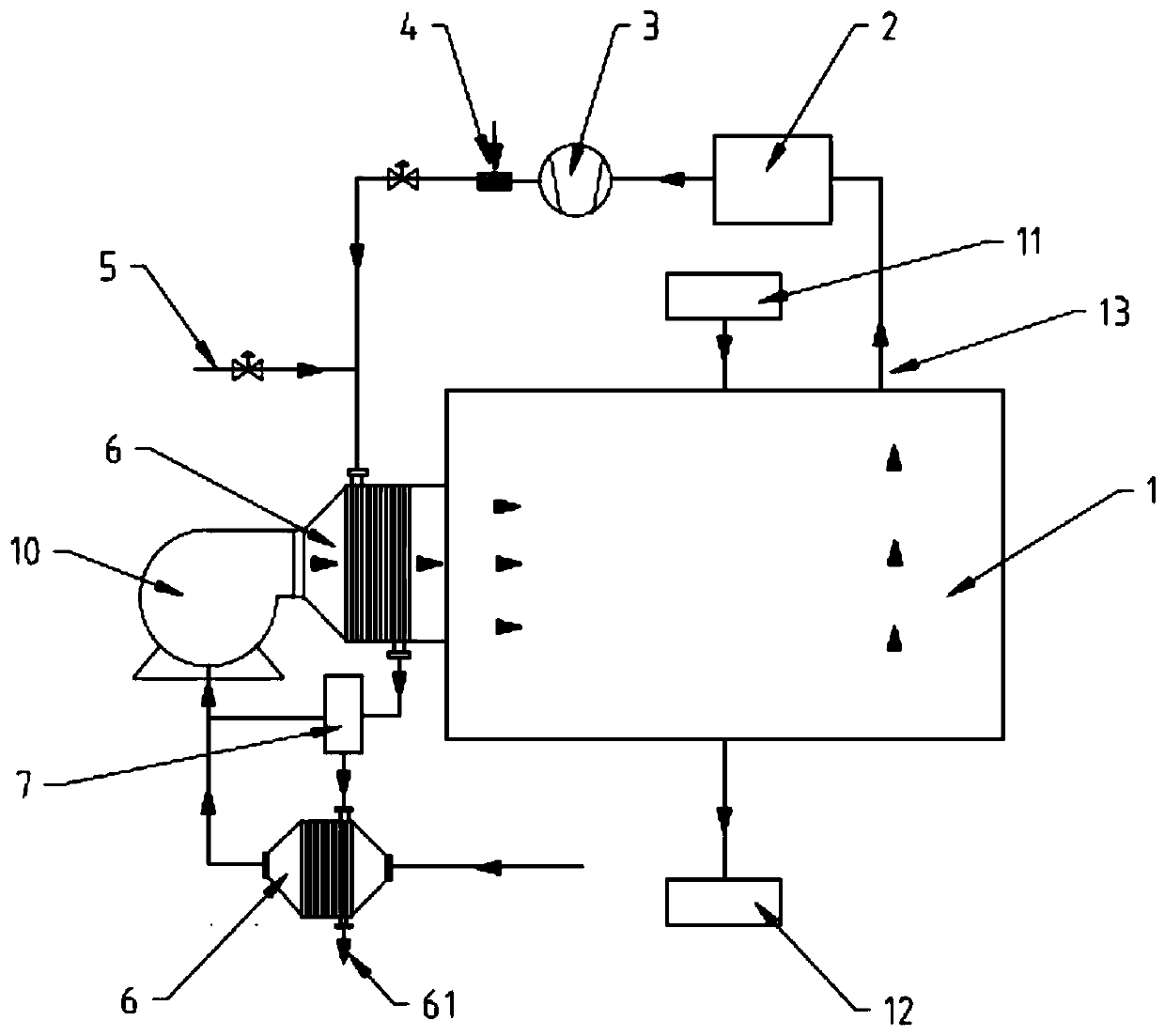

[0036] see figure 1 , figure 1 It is a structural schematic diagram of an integrated device for drying waste heat reuse in this embodiment, including a dryer 1, a media processor 2, a compressor 33, a shower 4 and a heat exchanger 6, and the upper part of the dryer 1 is provided with a material The inlet 11 and the waste gas outlet 13 are provided with a material outlet 12 at the lower part, and the high-temperature hot steam is discharged from the waste gas outlet 13 after drying the materials in the dryer 1 . The dryer 1 includes commonly used box dryers, vertical dryers, etc., which can dry all materials with a moisture content of 0-100%, and the moisture content of the dried materials can be between 0-100%. adjust.

[0037] Further, one end of the waste gas outlet 13 is connected to a media processor 2, and a filter is provided in the media processor 2, which can filter impurities in the waste gas. The media processor 2 includes but not limited to the following types: cy...

Embodiment 2

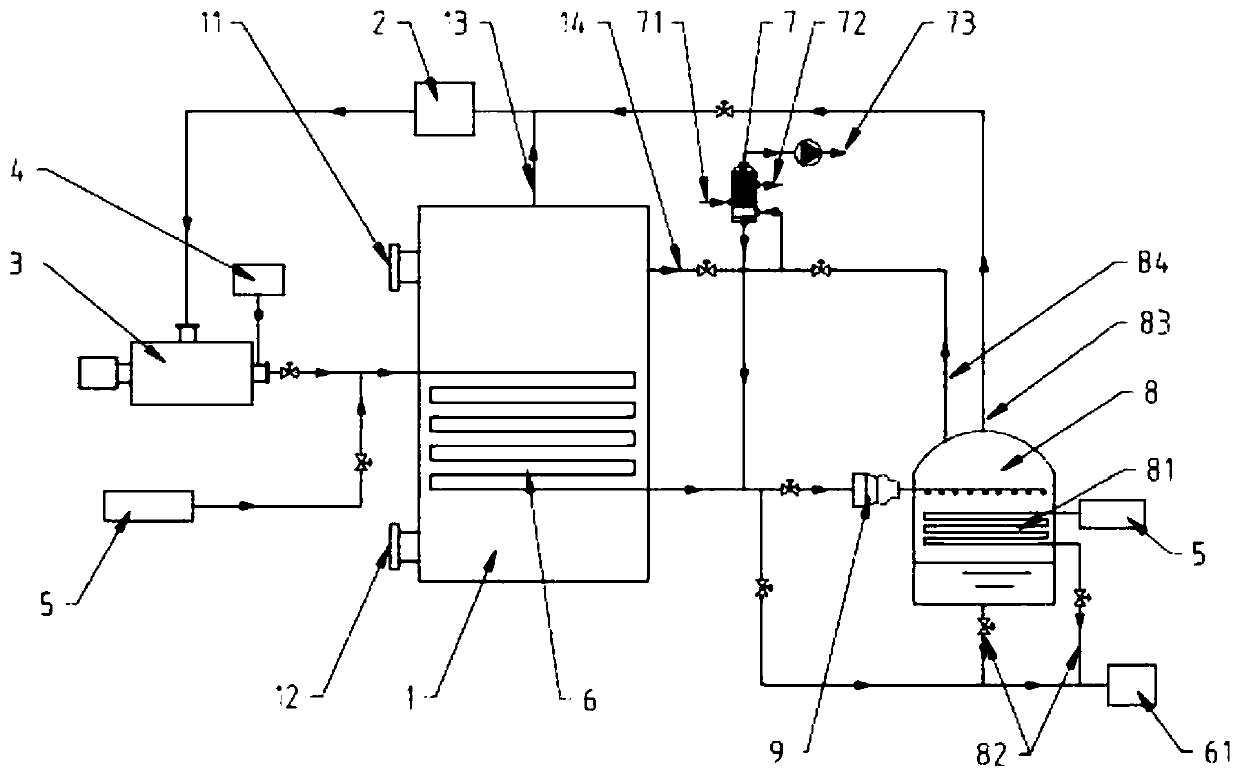

[0048] In Example 1, the heat exchanger 6 is externally connected to the dryer 1. In this example, the heat exchanger 6 is embedded in the dryer 1, which is realized by connecting the secondary steam recovery unit behind the heat exchanger 6. Recycling of hot steam.

[0049] Combine below figure 2 , the secondary steam recovery unit in this embodiment includes a flash tank 8 , and the heat exchanger 6 is connected to the flash tank 8 through a steam condensate pipe 61 . Preferably, a supercharger 9 is also connected between the steam condensate pipeline 61 and the flash tank 8, and the supercharger 9 introduces the hot steam in the steam condensate pipeline 61 into the flash tank 8 after pressurization .

[0050] Further, the flash tank 8 is provided with a coil heat exchanger 81, and the heat transfer medium such as steam, hot water, or heat transfer oil is passed through the coil heat exchanger 81. After entering the flash tank 8, the high-pressure saturated water become...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com