Drug coating layer and method for forming same

A drug coating, drug technology, used in coatings, drug combinations, pharmaceutical formulations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

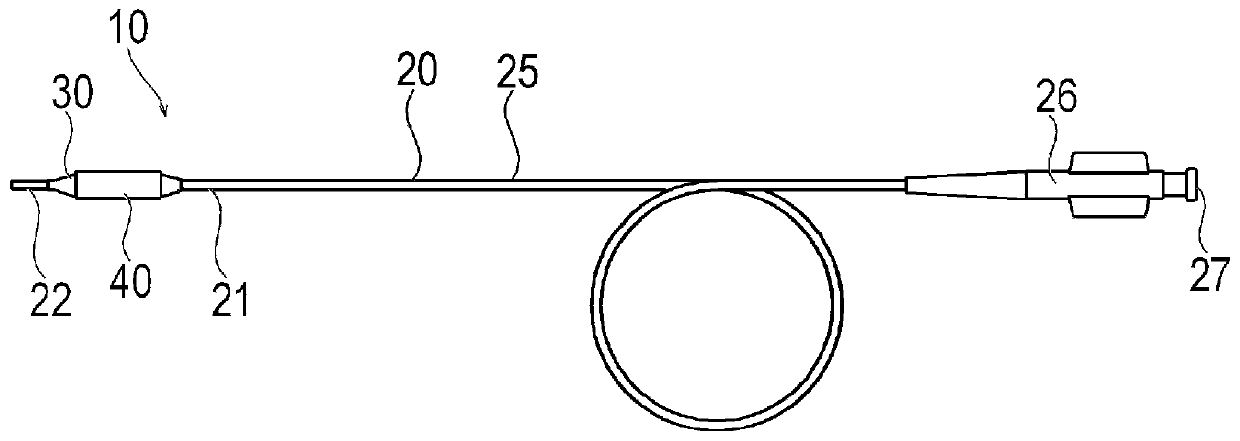

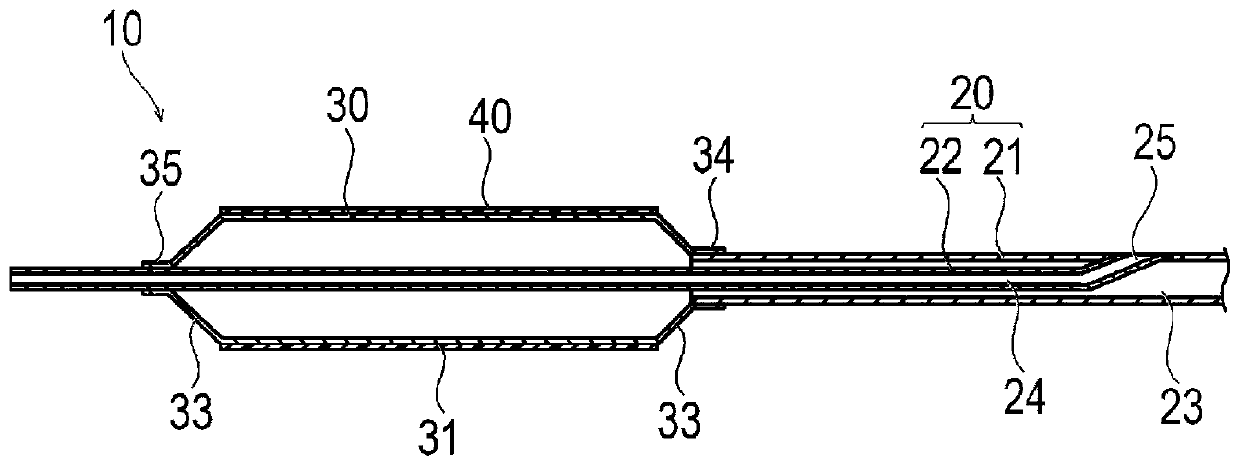

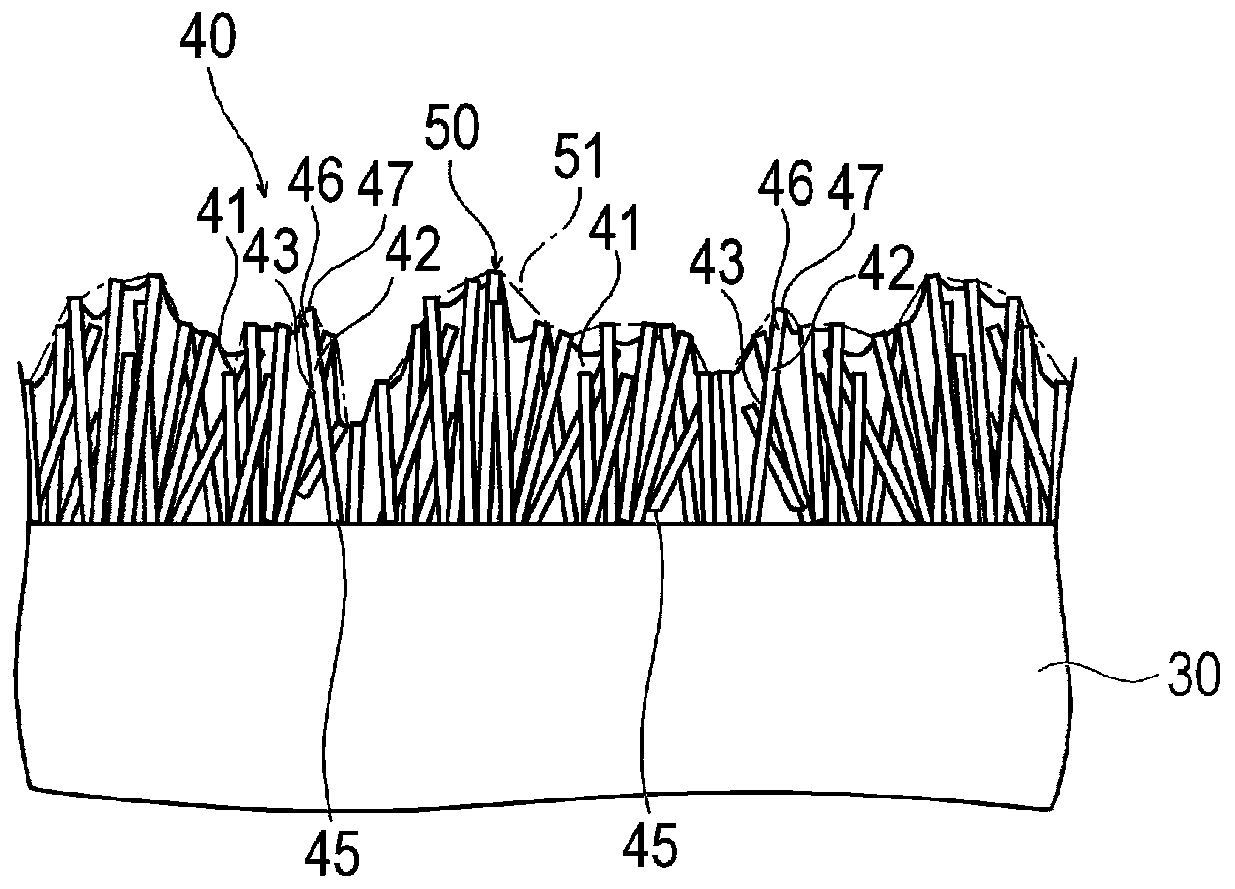

[0040] The drug coating 40 related to the first embodiment of the present invention is as Figure 1~3 As shown, it is installed on the surface of the balloon 30 of the drug-eluting balloon catheter 10 . In this specification, the side where the balloon catheter 10 is inserted into the lumen of the living body is referred to as the "distal side", and the side where the operation is performed is referred to as the "proximal side".

[0041] First, the structure of the balloon catheter 10 will be described. The balloon catheter 10 has a long catheter body 20 , a balloon 30 disposed on the distal portion of the catheter body 20 , a drug coating 40 disposed on the surface of the balloon 30 , and a hub fixed to the proximal end of the catheter body 20 . Section 26.

[0042] The catheter main body 20 has an outer tube 21 which is a tubular body whose distal end and proximal end are open, and an inner tube 22 which is a tubular body arranged inside the outer tube 21 . The inner tube...

no. 2 approach

[0120] The drug coating 140 related to the second embodiment is as Figure 11 As shown, it differs from the first embodiment in that it has a first additive layer 141 and a second additive layer 142 . In addition, the same code|symbol is attached|subjected to the part which has the same function as 1st Embodiment, and description is abbreviate|omitted.

[0121] The first additive layer 141 and the second additive layer 142 of the drug coating layer 140 according to the second embodiment are formed on the surface of the balloon 30 through different processes. As far as the first additive layer 141 is concerned, as Figure 11 Shown in (A), use aforementioned balloon coating device 60 (referring to Figure 4 ), supplying the first coating solution to the surface of the balloon 30. The first coating solution includes water-insoluble drug, first water-soluble additive, organic solvent and water. The first coating solution may be the same as or different from the coating solutio...

Embodiment 1

[0138] A drug coating having elongated bodies as crystals of a water-insoluble drug having a long axis, a first additive layer, and a second additive layer is formed. The constituent material of the drug-coated balloon in Example 1 is nylon 12, and the water-insoluble drug constituting the elongated body is paclitaxel. As for the water-soluble additive, ethyl serine was used as the first additive layer, and the same ethyl serine as that of the first additive layer was used as the second additive layer. The solvents of the first coating solution are tetrahydrofuran and acetone, and the solvents of the second coating solution are ethanol and water. The amount of the water-soluble low-molecular-weight compound is 500 parts by mass relative to 100 parts by mass of the water-insoluble drug. The photo of the drug coating of embodiment 1 is shown in Figure 14 .

[0139] The surface of the drug coating has a certain degree of undulation. The surface of the drug coating is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com