Application of rutile titanium oxide supported catalyst in carbon dioxide hydrogenation reaction

A supported catalyst, rutile-type technology, applied in the field of highly dispersed catalyst and its preparation and application, can solve the problems such as the inability to determine the maximization of precious metal utilization, the limitation of large-scale industrial production, the specification of metal dispersion, etc., and to improve the utilization of atoms. Efficiency, excellent reactivity, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: 1wt% Ru / r-TiO 2 Catalyst preparation

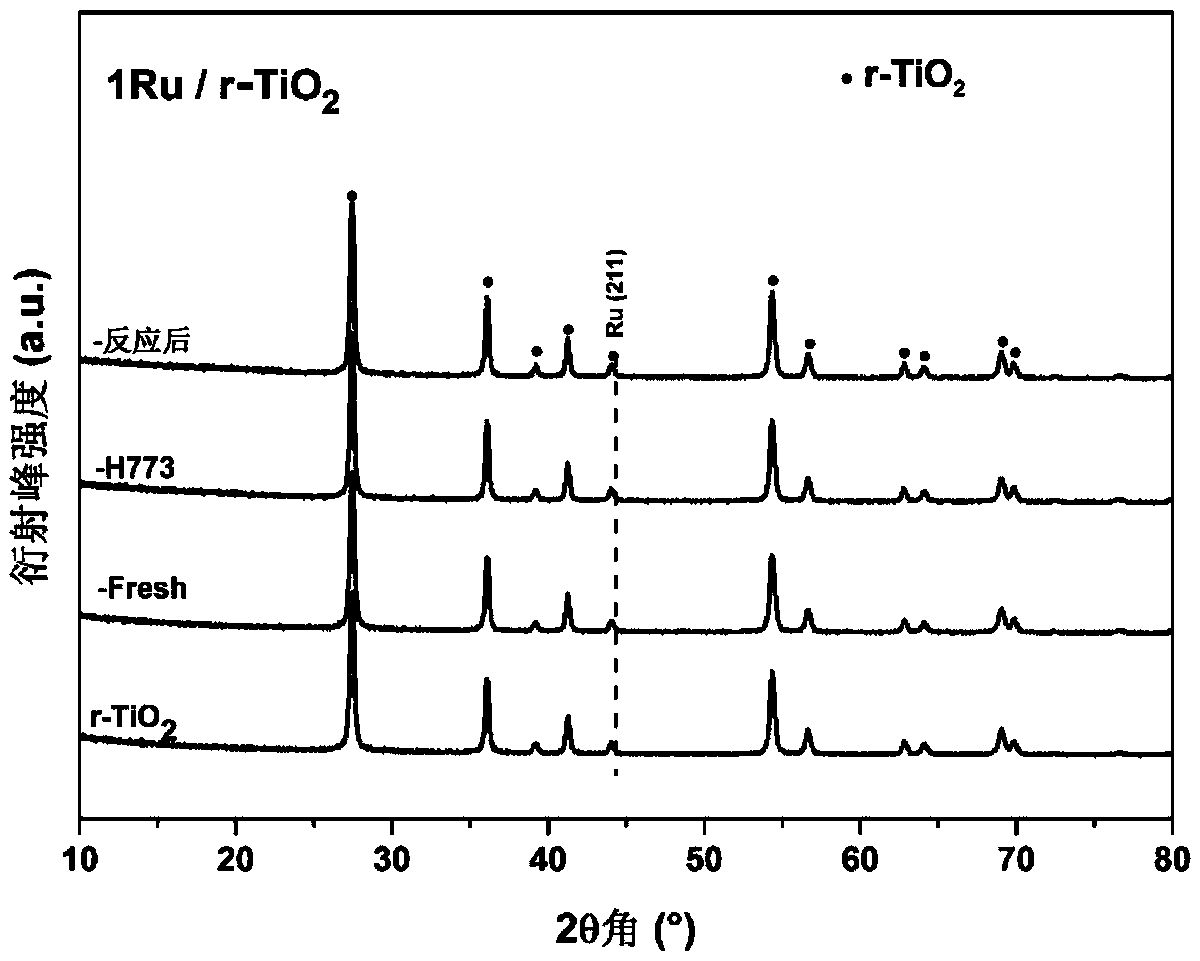

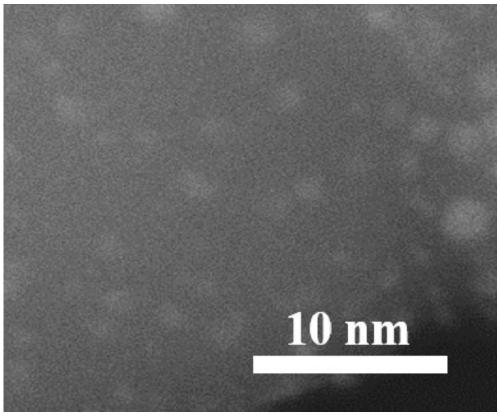

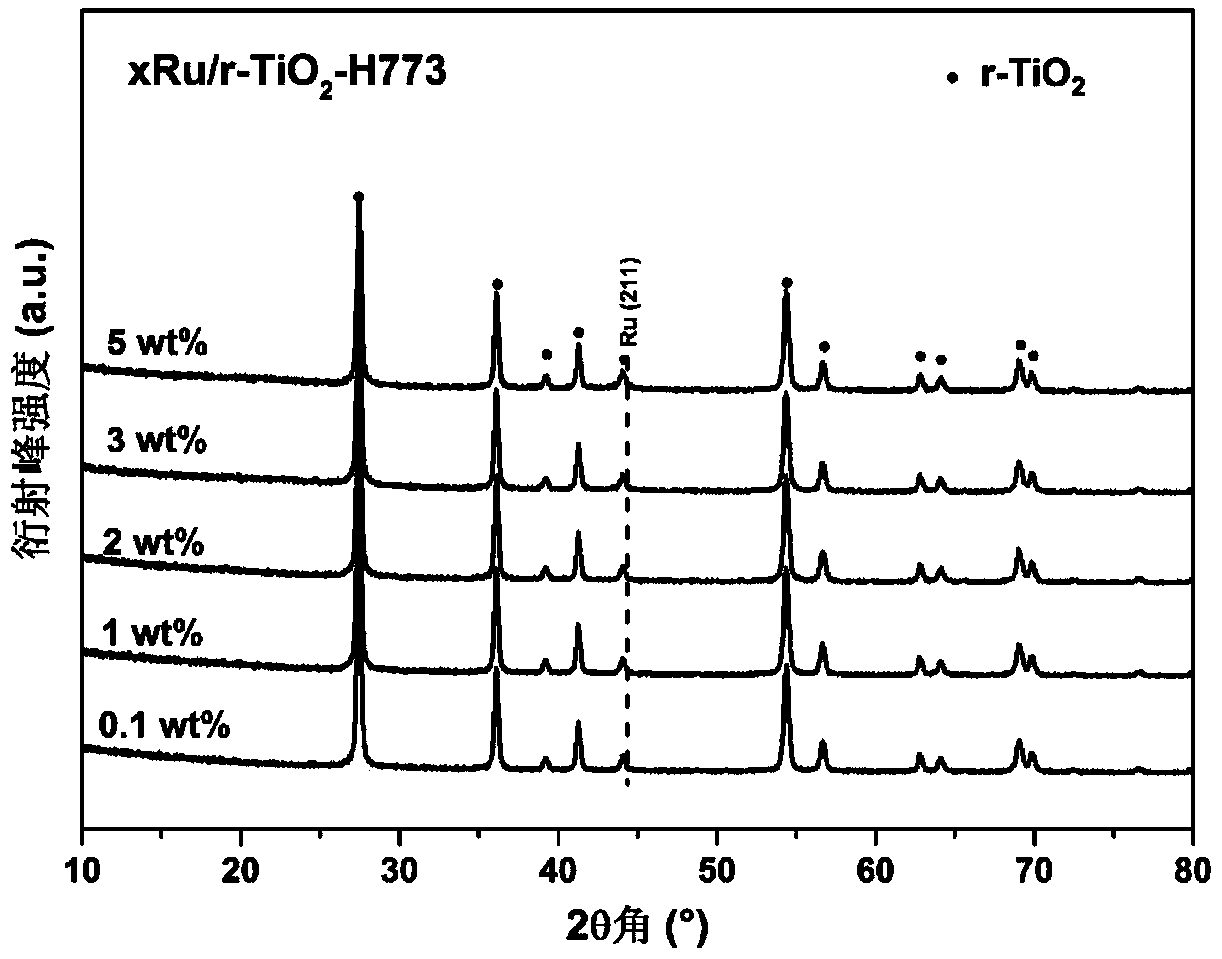

[0034] 31.25mL RuCl 3 Solution (Ru content is 0.32mg / mL) in a 100mL beaker, add 30mL ultrapure water, mix well, add 1g r-TiO 2 After 30 minutes, the mixed suspension was transferred to a 323K water bath, stirred until all the water was evaporated to dryness, and then the evaporated catalyst precursor was transferred to a 393K oven for drying. After grinding, 1wt% Ru / r- TiO 2 -fresh powder catalyst; put the above-prepared sample under a pure hydrogen atmosphere for 3h reduction at 773K to obtain 1wt% Ru / r-TiO 2 Powder catalyst, its XRD result sees figure 1 , the test results show that the noble metal Ru is highly dispersed on the surface of the catalyst or its nanoparticle size is smaller than the detection limit of XRD (3nm).

Embodiment 2-13

[0035] Embodiment 2-13: The preparation method is the same as that of Embodiment 1, and the specific conditions are shown in the table below.

[0036]

[0037]

Embodiment 14

[0038] Example 14: 1wt% Rh / r-TiO 2 Catalyst preparation

[0039] Compared with Example 1, the difference is that the added metal precursor solution is RhCl 3 solution. The specific steps are to take 10.20mL (Rh content is 0.98mg / mL) in a 100mL beaker, add 30mL ultrapure water, mix well and add 1gr-TiO 2 After 30 minutes, transfer the mixed suspension to a 323K water bath, stir until the water is completely evaporated, then transfer the evaporated catalyst precursor to a 393K oven for drying, and grind to obtain 1wt% Rh / r- TiO 2 -fresh powder catalyst. The above-prepared sample was placed in a pure hydrogen atmosphere at 773K for 3 hours to obtain 1wt% Rh / r-TiO 2 Powder catalyst, which is used for carbon dioxide conversion, in H 2 / CO 2 =4, GHSV=60000mL h -1 g cat -1 , the performance evaluation results are shown in Figure 8 , the test results show that the 1wt%Rh / r-TiO prepared by this method 2 With excellent catalytic performance, CH 4 The selectivity of >95%, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com