Catalyst system and method for preparing m-xylylenediamine

A technology of m-xylylenediamine and isophthalonitrile, which is applied in the field of catalytic hydrogenation, can solve the problems of high cost, lack of economic advantages, and difficulty in meeting the needs of long-term operation, and achieves the effect of high-efficiency operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

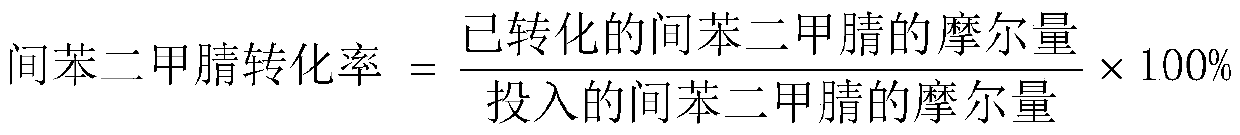

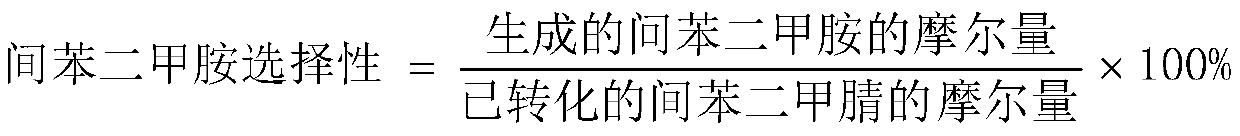

Image

Examples

Embodiment 1

[0076] 10mL of a commercially available 30%Co-3%Cr supported catalyst and 40mL of a commercially available 35%Ni-5%Fe supported catalyst (both mass fractions) were packed into the middle section of a 100mL fixed-bed reaction tube, and the catalyst based on Co on top of the Ni-based catalyst. Feed hydrogen reduction to activate the catalyst, the reaction temperature is set to 60°C, the reaction pressure is set to 13MPa, the hydrogen and isophthalonitrile molar ratio is 5:1, and the raw material is isophthalonitrile: ethanol: the mass ratio of liquid ammonia is 2:15:10 after mixing, the volume space velocity is 2.5h -1 Pump into the reaction tube to react. The reaction results are listed in Table 2.

Embodiment 2

[0078] 15mL of a commercially available 30%Co-3%Cr supported catalyst and 35mL of a commercially available 35%Ni-5%Fe supported catalyst (both mass fractions) were packed into the middle section of a 100mL fixed-bed reaction tube, and the catalyst based on Co on top of the Ni-based catalyst. Introduce hydrogen for reduction to activate the catalyst, the reaction temperature is set to 80°C, the reaction pressure is set to 12MPa, the molar ratio of hydrogen to isophthalonitrile is 8:1, and the raw materials are according to the mass ratio of isophthalonitrile: tetrahydrofuran: liquid ammonia After mixing at 1:1:10, the volume space velocity is 1.5h-1 Pump into the reaction tube to react. The reaction results are listed in Table 2.

Embodiment 3

[0080] 20mL of commercially available 30%Co-3%Cr supported catalyst and 30mL of commercially available 35%Ni-5%Fe supported catalyst (both mass fractions) were loaded into the middle section of a 100mL fixed-bed reaction tube, and the catalyst based on Co on top of the Ni-based catalyst. Feed hydrogen for reduction to activate the catalyst, the reaction temperature is set to 50°C, the reaction pressure is set to 6MPa, the molar ratio of hydrogen to isophthalonitrile is 6:1, and the raw material is isophthalonitrile: tetrahydrofuran: the mass ratio of liquid ammonia After mixing at 2:15:20, the volume space velocity is 1h -1 Pump into the reaction tube to react. The reaction results are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com