Efficient multi-source high-temperature and high-pressure aging kettle structure and aging method

A high-temperature, high-pressure and high-efficiency technology, which is applied to the structure of high-efficiency multi-source high-temperature and high-pressure aging kettles and the field of aging, can solve the problems of poor operation and use flexibility, low aging operation efficiency, and high maintenance and operation costs, so as to improve operation flexibility. and versatility, improve the efficiency of aging operations, and have the effects of a high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

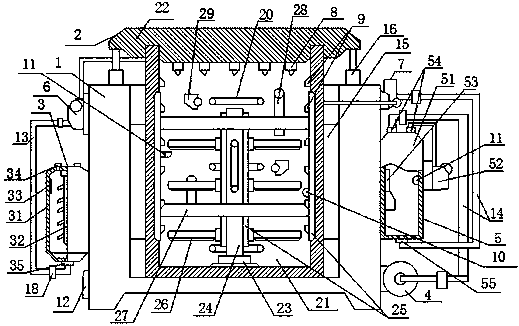

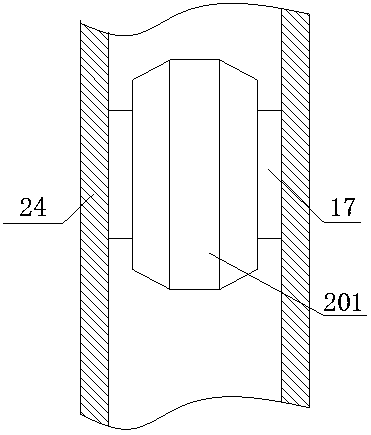

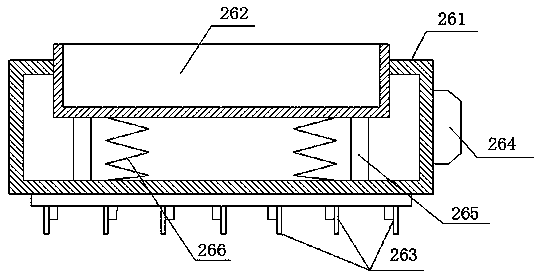

[0026] Such as figure 1 —3 shows a high-efficiency multi-source high-temperature and high-pressure aging kettle structure, including a load frame 1, a reaction kettle 2, a liquid medicine buffer tank 3, an oxygen storage tank 4, a gas mixing tank 5, a spray pump 6, and a jet pump 7 , spray outlet 8, jet air outlet 9, temperature and humidity sensor 10, air quality sensor 11 and drive circuit 12, wherein the reaction kettle 2 is a closed cavity structure whose axis and horizontal plane are vertically distributed, embedded in the bearing frame 1 and connected with the bearing Frame 1 is coaxially distributed, spray outlets 8 and jet outlets 8 are several and embedded in reactor 2, spray outlets 8 are connected to the top of reactor 2 and evenly distributed around the axis of reactor 2, jet outlets 9 surround reactor The 2 axes are evenly distributed on the side wall of the reactor 2, and its axis intersects with the axis of the reactor 2. The spray outlets 8 and jet air outlets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com