Device and method for multi-optical-fiber high-speed rotating wiredrawing side face fusion beam combination

A high-speed rotation and multi-fiber technology, applied in the field of optical fiber devices, can solve the problems of low coupling efficiency and complex process of combining optical fibers, and achieve the effect of simple production, simple process operation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

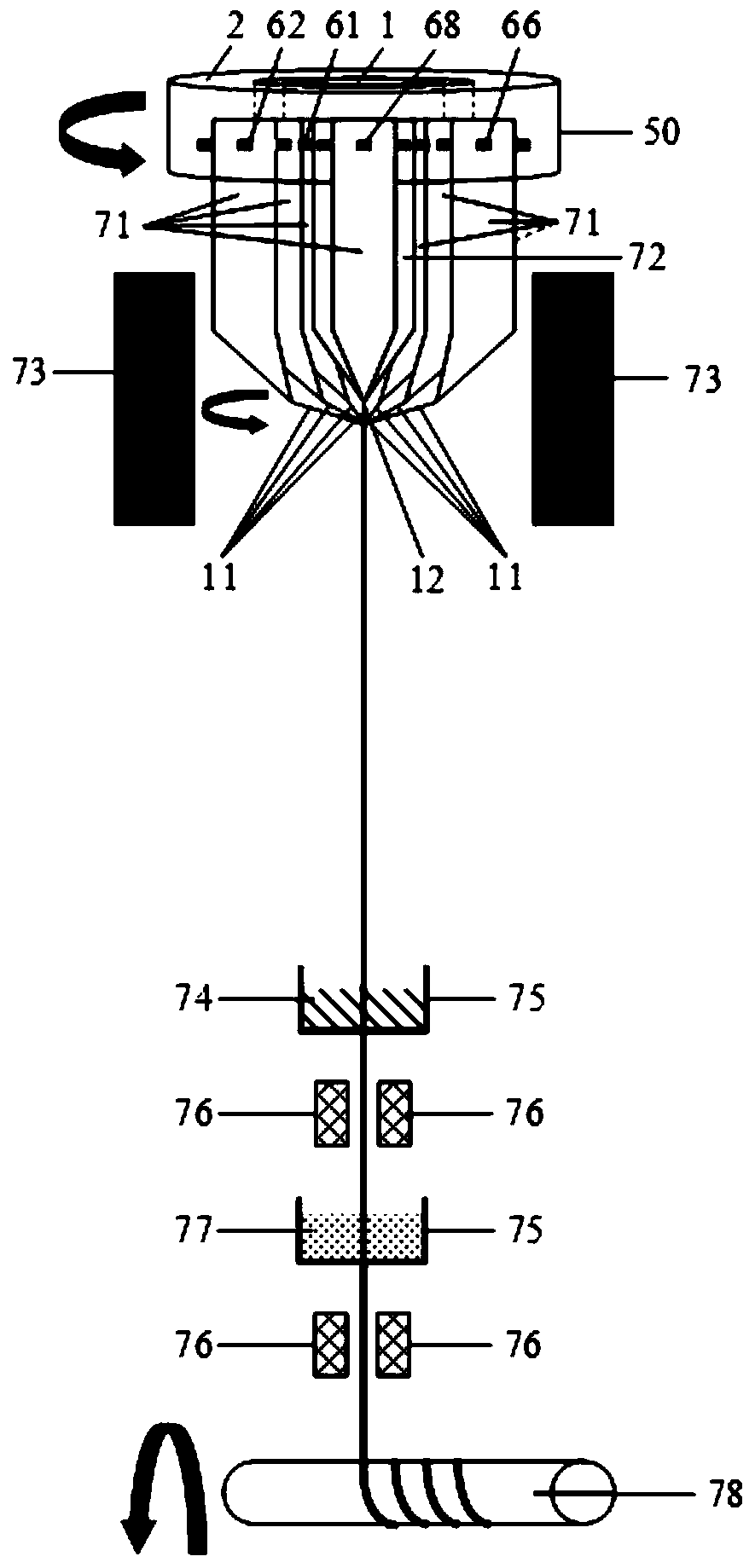

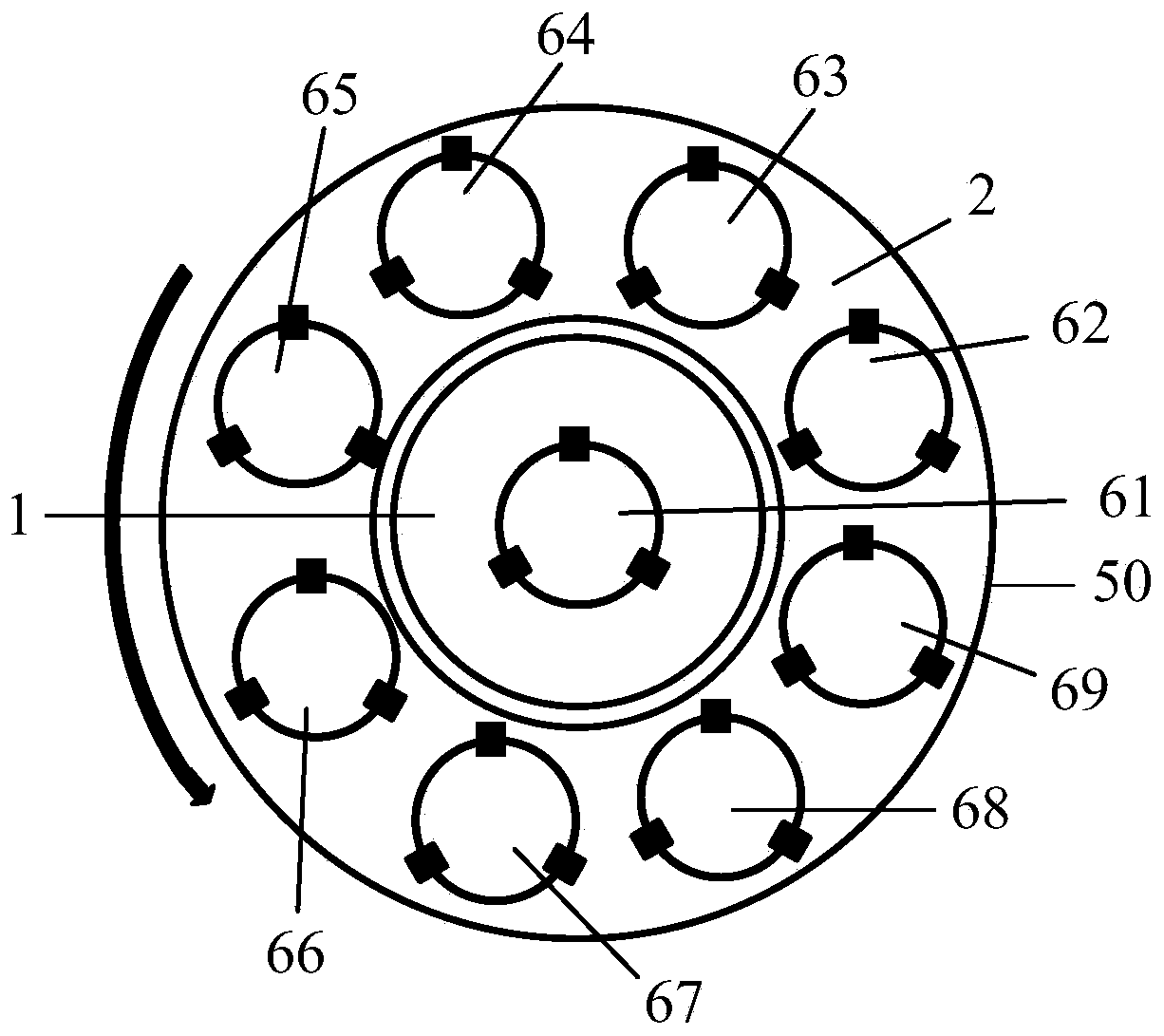

[0064] This embodiment is based on Embodiment 1, which discloses a method for bundling using a multi-fiber high-speed rotating drawing side fusion bundling device. In this embodiment, the diameter of the active fiber to be prepared is 400um, and the diameter of the pump fiber is Take 250um as an example for (1+1) composite function fiber to illustrate:

[0065] like Figure 10 As shown, the specific detailed steps of the (1+1) type composite functional fiber are as follows:

[0066] Step 1: Prepare an active optical fiber preform 12 with a diameter of about 32 mm and a pump optical fiber preform 11 with a diameter of about 20 mm, and all the preforms have the same length of 90 cm;

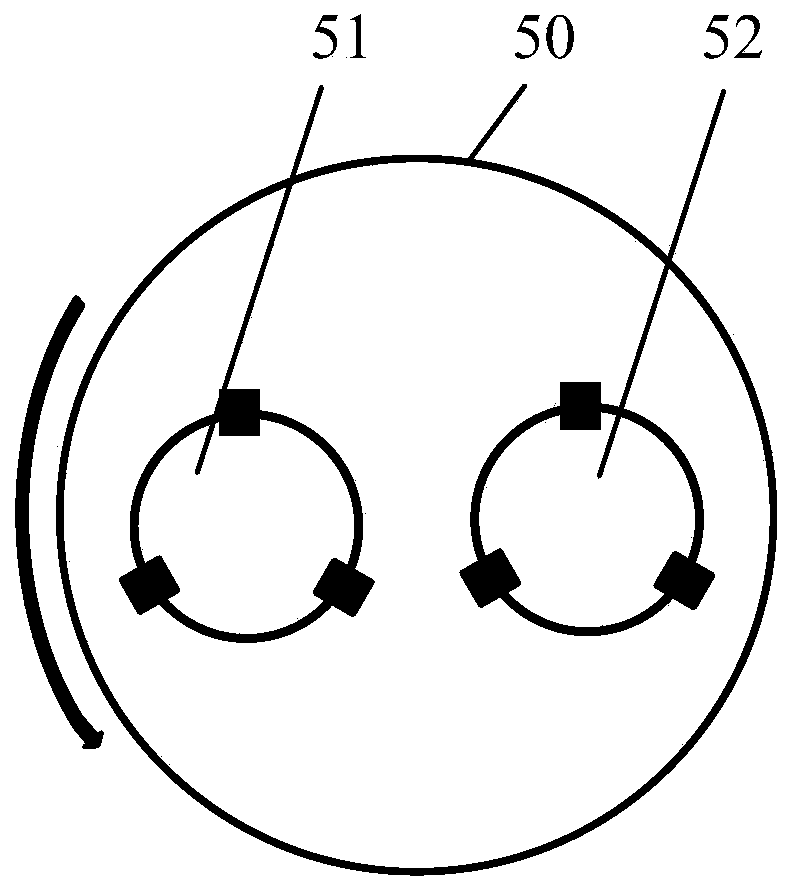

[0067] Step 2: Use such as figure 2 The shown structural schematic diagram of the chuck 50, a pump optical fiber preform 11 is clamped on the gripper 52, and the active optical fiber preform 72 is clamped on the gripper 51;

[0068] Step 3: The two optical fiber preforms fixed on the drawing to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com