Large-scale integral thin-wall carbon/ceramic composite material gas limiting cylinder and preparation method thereof

A kind of ceramic composite material and overall technology, which is applied in the thin-walled carbon/ceramic composite material and its preparation field, can solve the problems of increased production cost, insufficient rigidity of the prefabricated body, easy deformation, etc., and achieve reliability and service life Long life, save high-value materials, good anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention is given in detail below, it should be noted that the detailed description of the present invention is for the convenience of a comprehensive understanding of the technical essence of the present invention, and should not be regarded as limiting the scope of protection of the claims of the present invention .

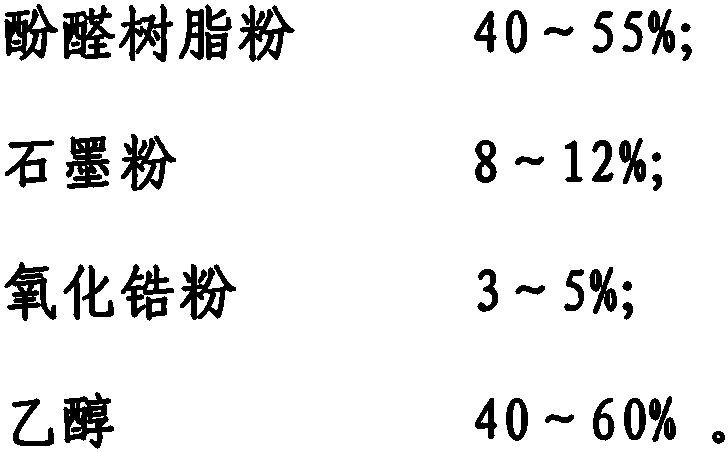

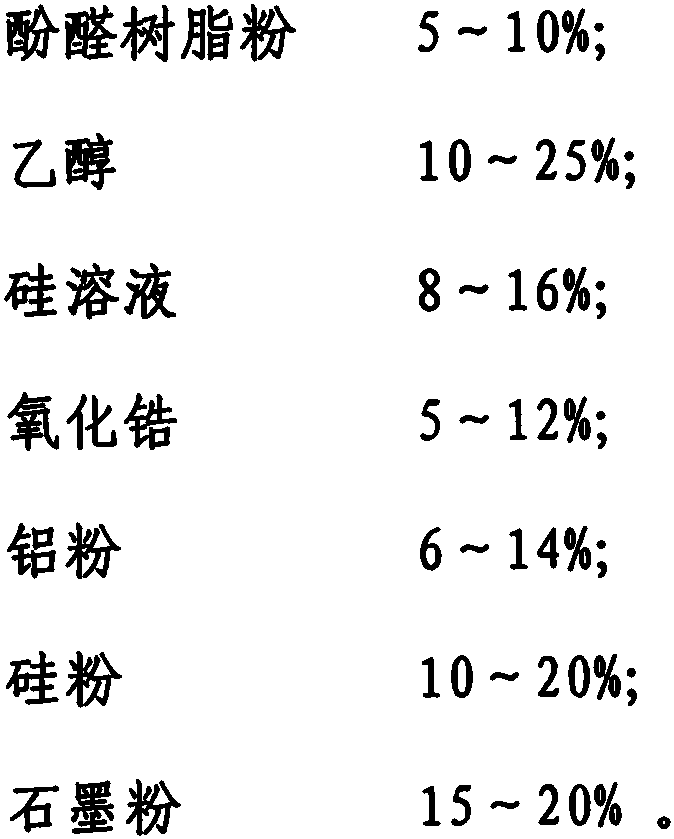

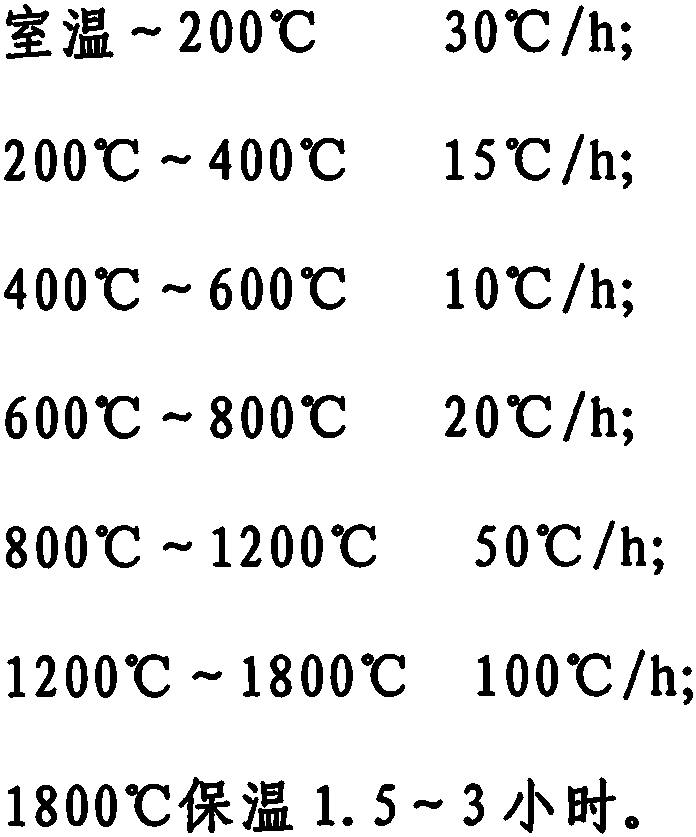

[0026] The technical solution of the specific embodiment of the large-scale integral thin-walled carbon / ceramic composite gas-limiting cylinder of the present invention is: comprising a cylinder body, the key of which is that the composition of the cylinder body is glass fiber cloth impregnated with modifier and pre-treated The carbon fiber cloth impregnated with the adhesive is composited into a hybrid fiber cloth, which is wound to obtain a cylinder, and then subjected to high temperature treatment to obtain the gas-limiting cylinder. During the above-mentioned high temperature treatment process, the hybrid fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com