Production process of breathable printed fabric

A production process and breathable technology, applied in printing, printing devices, textiles and papermaking, etc., can solve the problems of airtightness, limited glue printing, breathability, poor moisture permeability, etc., and achieve the effect of high viscosity and poor fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

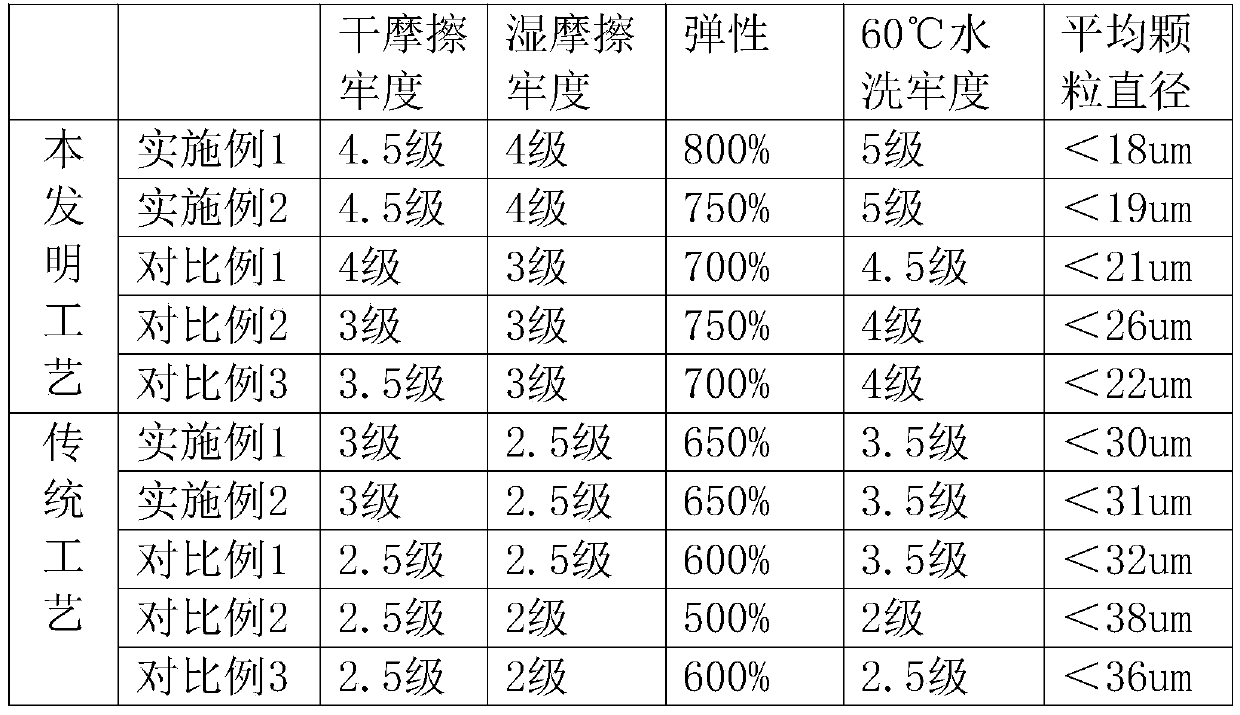

Embodiment 1

[0040] A kind of printing glue, is made up of following material in parts by weight:

[0041] 100 parts of carboxymethyl starch;

[0042] 400 parts of acrylic acid;

[0043] 200 parts of modified acrylic acid oligomers;

[0044] 1800 parts of sodium hydroxide;

[0045] 3 parts of potassium persulfate;

[0046] 1.2 parts of N, N'-methylenebisacrylamide;

[0047] 2500 parts of deionized water;

[0048] 150 parts of titanium dioxide;

[0049] 5 parts of anti-blocking agent;

[0050] 25 parts of ethylene oxide;

[0051] 25 parts of paraffin;

[0052] Silica 25.

[0053] The preparation method of the modified acrylic acid oligomer is as follows: add 50 parts of (3-glycidoxypropyl)methyldiethoxysilane into the reaction kettle, and remove water under vacuum at 120° C. for 1.5 hours; Then add 2 parts of xylidine to the reaction kettle, raise the temperature to 100°C, add 50 parts of acrylic acid dropwise, control the dropwise addition within 25 minutes, and react for 7 hours...

Embodiment 2

[0059] A kind of printing glue, is made up of following material in parts by weight:

[0060] 200 parts of carboxymethyl starch;

[0061] 1200 parts of acrylic acid;

[0062] 600 parts of modified acrylic oligomers;

[0063] 3600 parts of sodium hydroxide;

[0064] 9 parts of potassium persulfate;

[0065] 3.6 parts of N, N'-methylenebisacrylamide;

[0066] 500 parts of deionized water;

[0067] 300 parts of titanium dioxide;

[0068] 10 parts of anti-blocking agent;

[0069] 50 parts of ethylene oxide;

[0070] 50 parts of paraffin;

[0071] 50 parts of silicon dioxide.

[0072] The preparation method of the modified acrylic acid oligomer is as follows: add 100 parts of (3-glycidoxypropyl)methyldiethoxysilane into the reaction kettle, and remove water under vacuum at 120° C. for 2 hours; then Add 5 parts of xyleneamine to the reaction kettle, raise the temperature to 120°C, add 100 parts of acrylic acid dropwise, control the dropwise addition within 30 minutes, and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com