Exhaust pipe insulation cover assembly and production method thereof

A technology of exhaust pipe and shield, which is applied in the field of exhaust pipe shield assembly and its preparation, and can solve the problems of exhaust pipe shield assembly appearance wrinkles, metal plate and ceramic fiber board falling off, heat shield failure, etc. , to achieve the effect of improving surface strength, increasing service life and improving heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

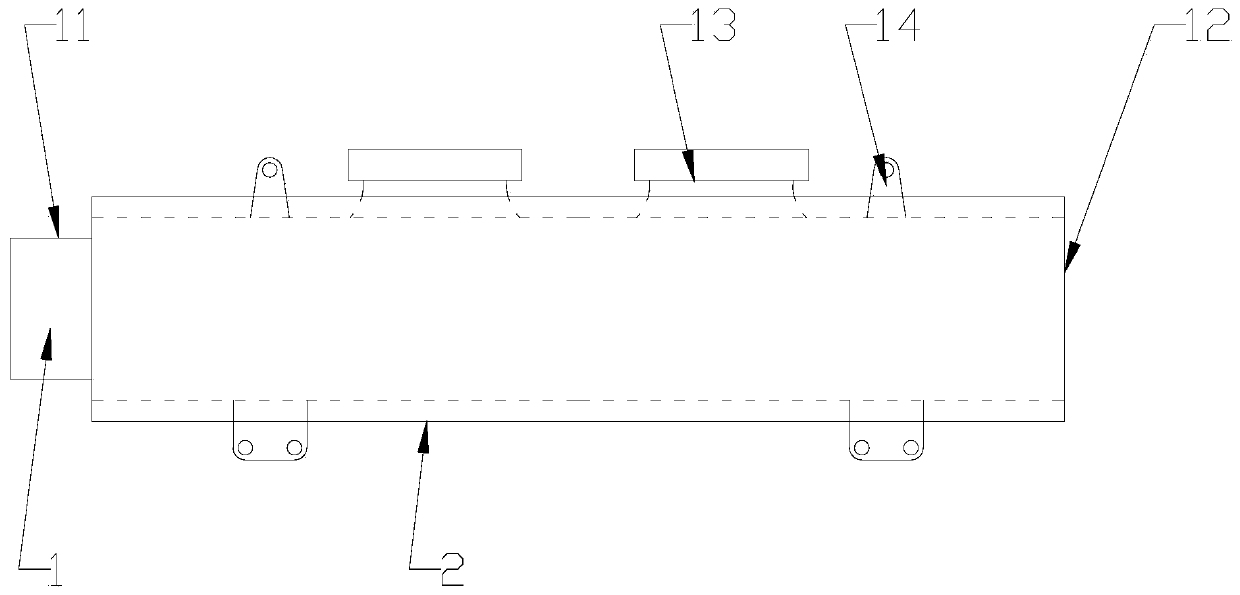

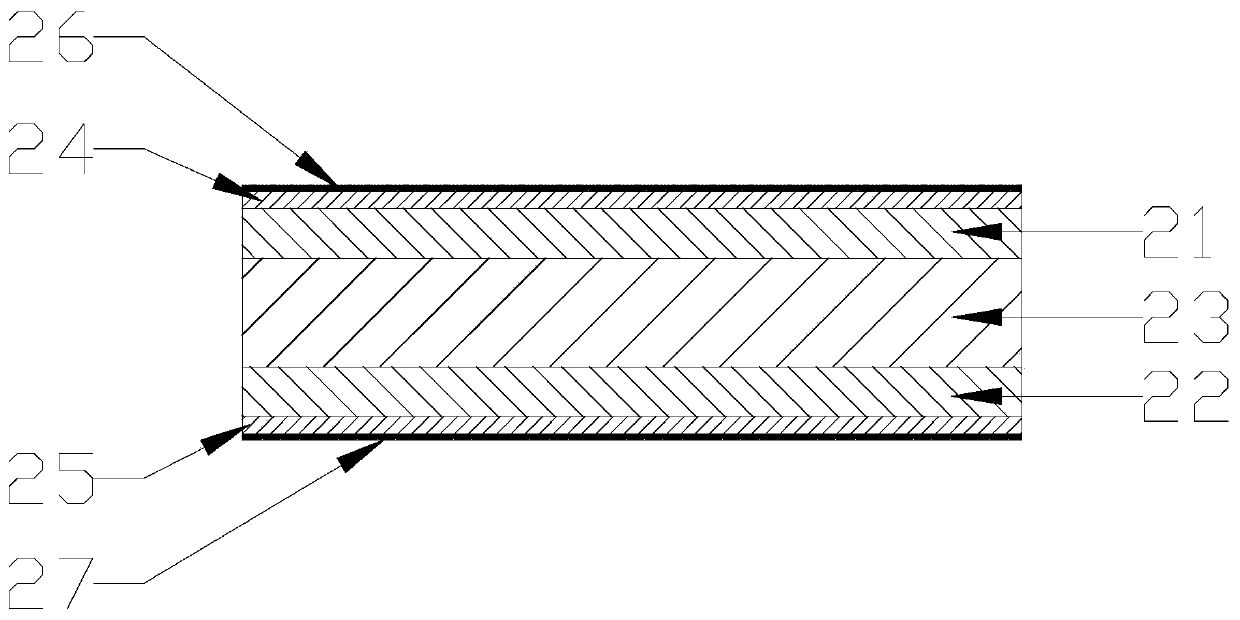

[0022] refer to figure 1 and figure 2 , an exhaust pipe shield assembly of the present invention, comprising an exhaust pipe 1 and a heat shield 2, the two ends of the exhaust pipe 1 are respectively provided with an air outlet 11 and a first air inlet 12, the exhaust pipe The side wall of the trachea 1 is provided with several second air inlets, and the air intake branch pipe 13 is fixed on the second air inlet, and several connecting plates 14 are also provided on the side wall of the exhaust pipe 1, The heat shield 2 is respectively provided with a plurality of first gaps and second gaps for the intake branch pipe 13 and the connecting plate 14 to protrude. The heat shield 2 includes a first heat insulation felt layer 21, a second insulation The thermal felt layer 22, the heat insulating fiber layer 23 between the first heat insulating felt layer 21 and the second heat insulating felt layer 22, the first hard shell layer 24 on the top surface of the first heat insulating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com