Double-stacking type LNG gas supply device

A gas supply device, superimposed technology, applied in the installation device of container structure, equipment loaded into pressure vessel, gas/liquid distribution and storage, etc., can solve problems such as toxic and harmful, impact on use safety, loss of profitability for users, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can understand.

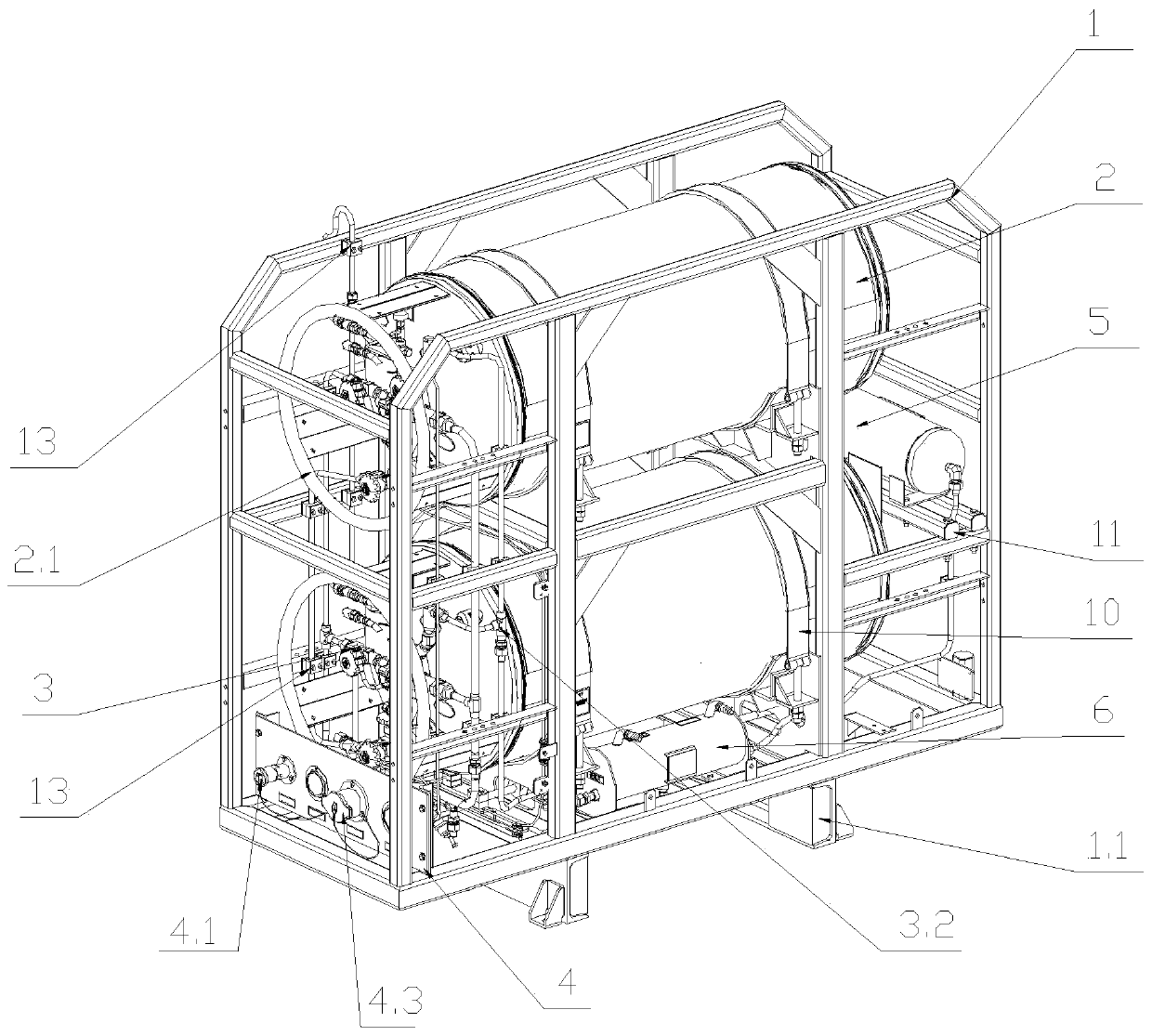

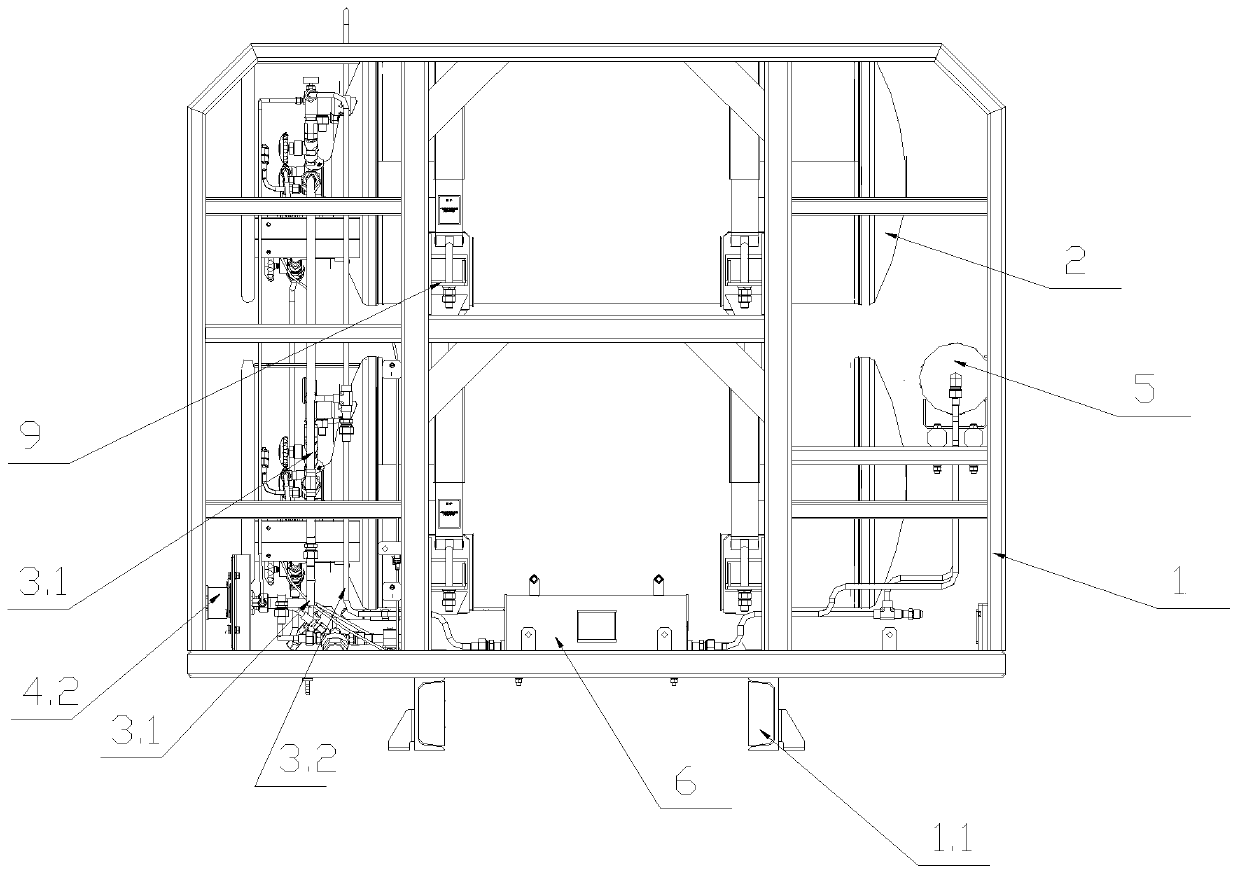

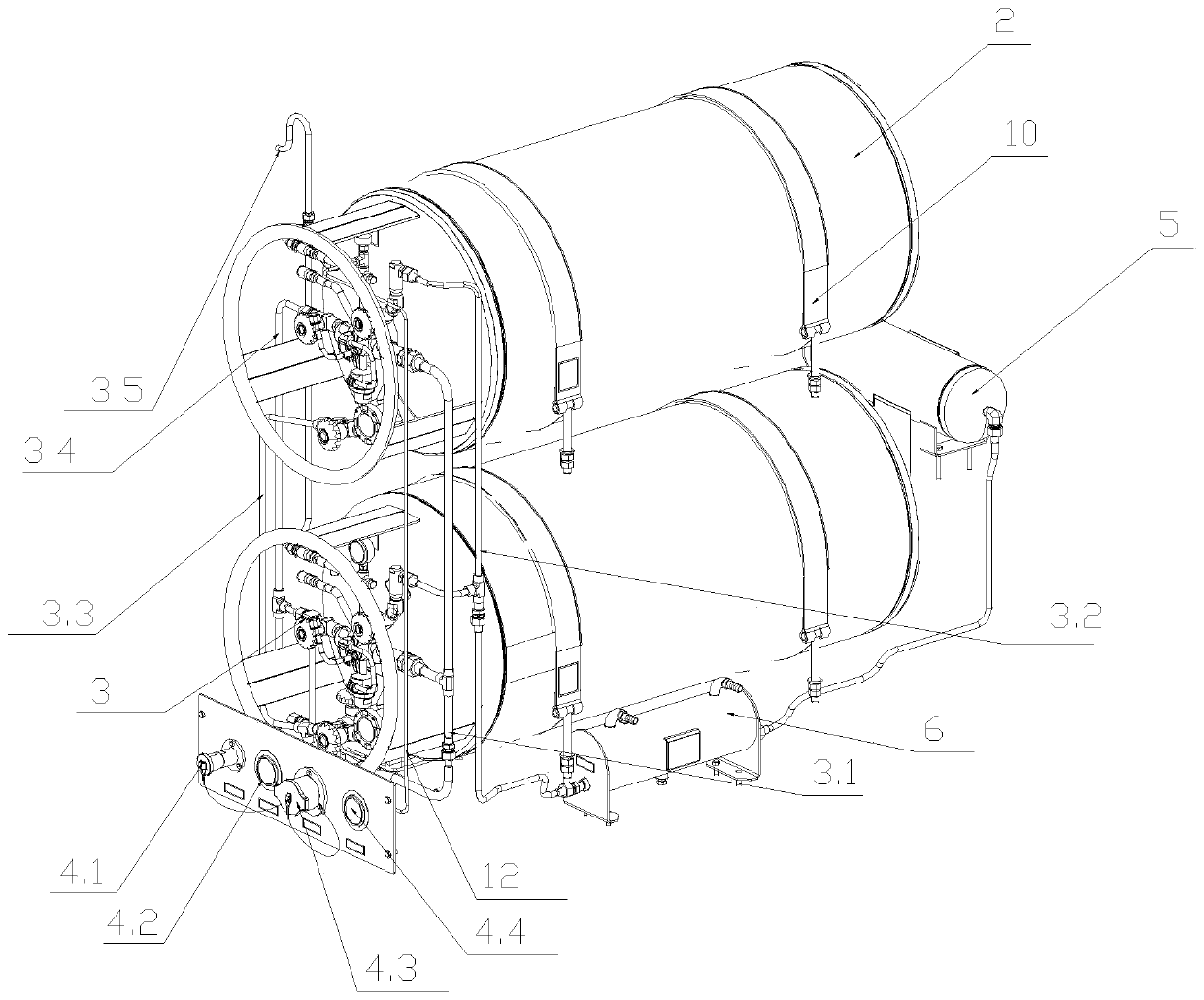

[0031] Such as Figure 1-9 The double-stacked LNG gas supply device shown includes a frame assembly 1, and the bottom of the frame assembly 1 is symmetrically provided with a frame longitudinal beam 1.1 connected to the vehicle girder;

[0032] Two LNG gas cylinders 2 are superimposed on the upper and lower layers in the frame assembly 1. Two sets of cable tie fixing frames 9 are arranged on the upper and lower sides of the frame on both sides of the frame assembly 1. Between the cable tie fixing frames 4 are arranged The cable tie 10 of the LNG cylinder 2;

[0033] The air inlet end of the LNG cylinder 2 is provided with a gas cylinder inlet and outlet pipeline assembly 3, and the end of the LNG cylinder 2 is provided with a protective frame 2.1 for protecting the gas cylinder inlet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com