Supercritical water oxidation system taking air as oxidant and starting method thereof

A technology of supercritical water oxidation and oxidant, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc. The effect of continuous operation is stable, investment cost is reduced, and operating cost is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

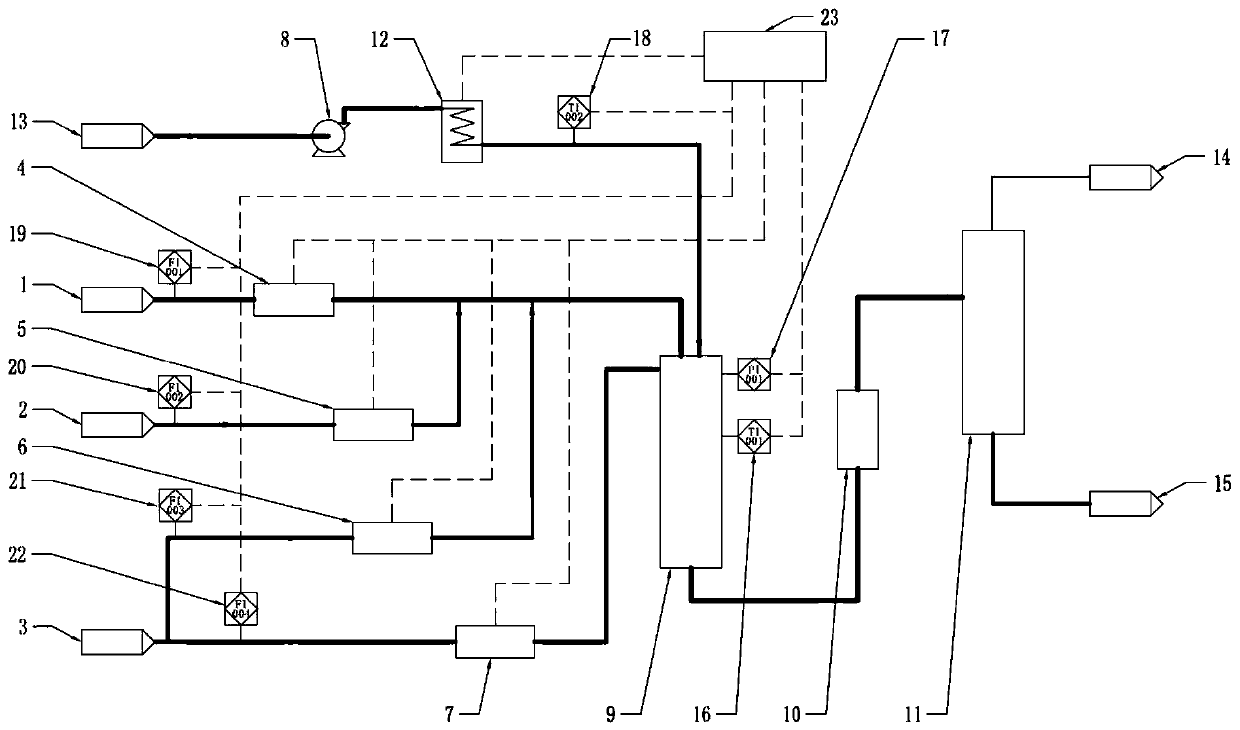

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] The supercritical water oxidation system with air as the oxidant includes a material feeding structure, a reactor 9, a pressure reducing device 10, a gas-liquid separator 11 and a controller 23, and the material feeding structure includes an oxidant feeding device, an organic waste liquid feeding device, auxiliary fuel feed device, feed softened water device and partition softened water feed device, oxidant feed device, organic waste liquid feed device, auxiliary fuel feed device, feed softened water device and partition softened water feed device The device includes an oxidant source 13, an organic waste liquid source 1, an auxiliary fuel source 2, a softened water source 3, an oxidant feed adjustment device, an organic waste liquid feed adjustment device 4, an auxiliary fuel feed adjustment device 5, and a feed softened water adjustment device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com