Conductive elastomer and preparation method thereof

A technology of elastomers and thermoplastic elastomers, applied in the field of materials, can solve problems such as low tensile strength and elongation at break, high resistivity, and hindering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A preparation method of a conductive elastomer, comprising the steps of:

[0019] Step 1, dissolving the conductive filler in an organic solvent, so that the conductive filler is evenly dispersed to obtain the dispersed conductive filler;

[0020] Step 2. After uniformly mixing the dispersed conductive filler with the fiber-forming polymer, remove the organic solvent, then banbury at 200-250°C for 2-5 minutes with an internal mixer, then cool and crush to make conductive masterbatch;

[0021] Step 3: The conductive masterbatch and the thermoplastic elastomer are evenly mixed, heated and melted, and then multi-stage stretched and extruded to form a conductive elastomer composite material.

[0022] The above manufacturing steps have the following advantages:

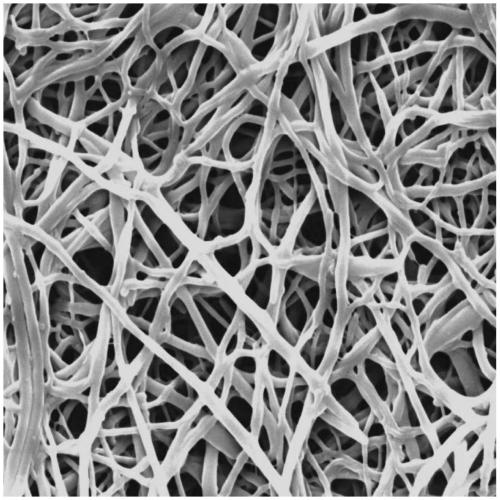

[0023] 1. Prepare conductive masterbatch with easy fiber-forming polymer as carrier. After multi-stage stretching, the conductive masterbatch forms a conductive microfiber network in the thermoplastic elastomer, a...

Embodiment 1

[0026] 65 parts of POE elastomer (polyolefin elastomer), 20 parts of polylactic acid, and 15 parts of conductive carbon black were prepared according to the above-mentioned preparation method. The volume resistivity of the prepared CB / PLA / POE elastomer composite was 4.4×10 5 Ω·cm, tensile strength 8.2MPa, elongation at break 1804%.

Embodiment 2

[0028] 68 parts of POE elastomer (polyolefin elastomer), 20 parts of polybutylene terephthalate, and 12 parts of multi-walled carbon nanotubes. The volume resistivity of the prepared MWCNT / PBT / POE elastomer composite was 8.6×10 4 Ω·cm, tensile strength 7.6MPa, elongation at break 1700%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com