A ceramic particle planting process based on spark discharge

A technology of ceramic particles and spark discharge, which is applied in the coating process and coating of metal materials, can solve the problems of weak bonding force, large wear resistance loss of abrasive mechanical properties, abrasive thermal damage, etc., and achieves low equipment investment, The effect of fast speed and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The metal substrate of this embodiment is the high-temperature alloy Inconel625, and the surface to be planted is polished with 600# and 1500# sandpaper, and then ultrasonically cleaned with anhydrous alcohol, and then dried with an electric hair dryer for later use.

[0031] A spark discharge deposition electrode with a diameter of 4 mm and a length of 60 mm was cut from a powder metallurgy sintered Ni-based alloy (NiCoCrAlYTa) block by wire cutting.

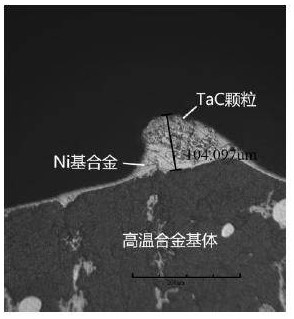

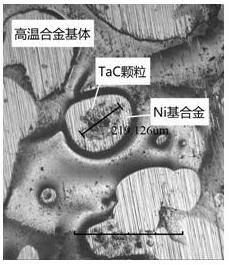

[0032]TaC ceramic particles (conductive ceramics, no need to prepare a conductive film) are selected as the planting particles, with a particle size of -100 mesh to +150 mesh and an irregular shape. Spread TaC ceramic particles evenly on the surface of the superalloy substrate, use electric spark deposition equipment, connect the electrode to the positive electrode, and the metal substrate to the negative electrode, and adjust the process parameters: discharge voltage 100-120V, capacitance 350-420μF, discharge frequency 3...

Embodiment 2

[0034] The metal substrate of this embodiment is made of high-temperature alloy DZ125L, and the surface to be planted is polished with 600# and 1500# sandpaper, then ultrasonically cleaned with anhydrous alcohol, and then dried with an electric hair dryer for later use.

[0035] A spark discharge deposition electrode with a diameter of 5 mm and a length of 80 mm was cut from a Ni-based alloy GH4169 block by wire cutting.

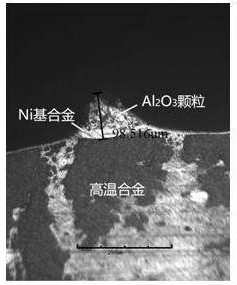

[0036] Choose Al 2 o 3 Ceramics are used as planting particles with a particle size of -100 mesh to +150 mesh and an irregular shape. Because Al 2 o 3 Ceramics are poor conductors of electricity. Before the particles are planted, a conductive film needs to be prepared on the surface. The material of the conductive film is pure Ni, and the electroless plating process is adopted. The thickness of the conductive film is 22 μm. Will Al 2 o 3 The ceramic particles are evenly spread on the surface of the superalloy substrate, and the electric spark depositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com