Phase-based partial discharge generation device and method with adjustable discharge capacity and density

A partial discharge and generating device technology, applied in the field of partial discharge generating devices, can solve the problems of large and complex equipment, inconvenient to carry and use, and achieve the effects of ensuring stability and reliability, improving drawing ability, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

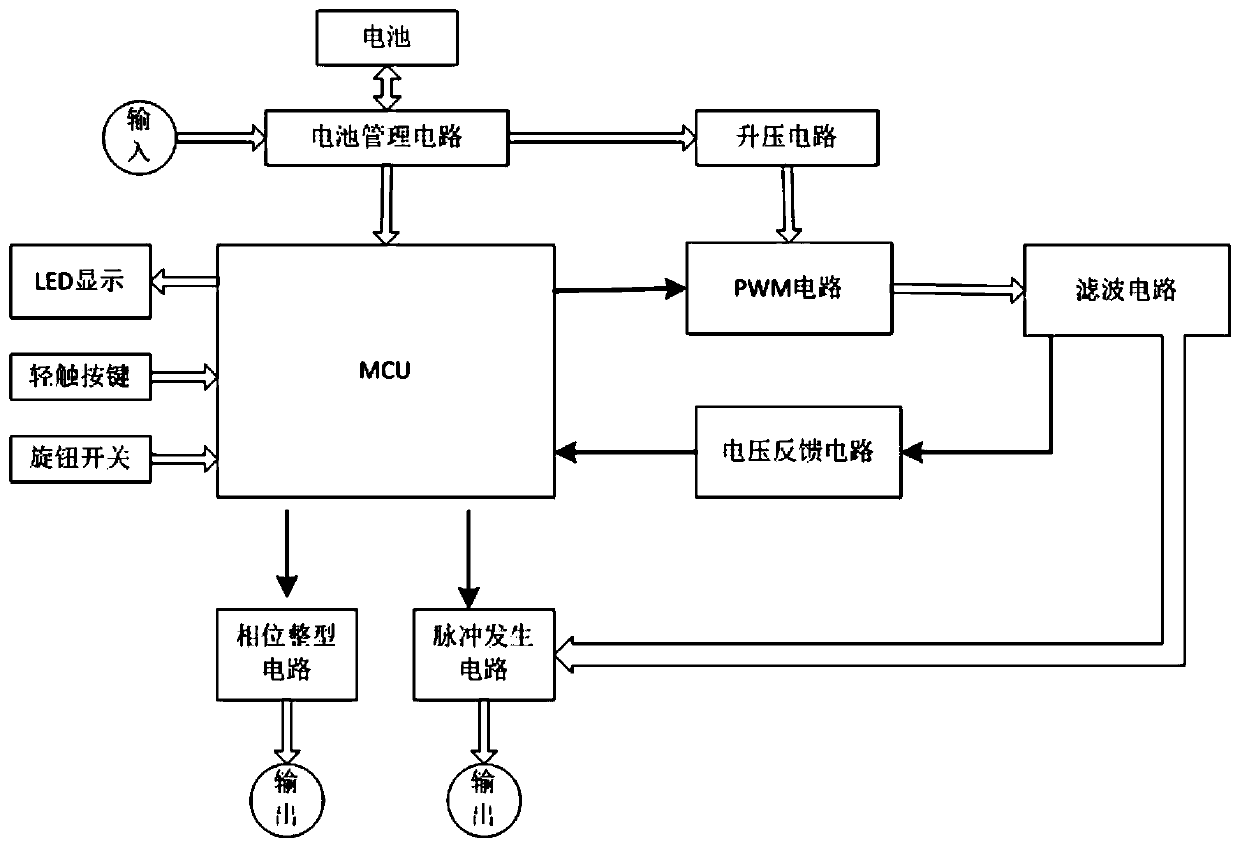

[0039] Such as figure 1 As shown, Embodiment 1 of the present disclosure provides a phase-based partial discharge generation device with adjustable discharge volume and density, including a main control unit (MCU), a PWM circuit module, a filter circuit module, a pulse generation circuit module, a phase adjustment Type circuit module, button module and knob switch module;

[0040] The main control unit is used to adjust parameter settings, output phase pulses, and manage discharge voltage and discharge time according to the received input of buttons and knob switches;

[0041] The pulse generation circuit module is used to generate discharge pulses according to the instructions of the main control unit, and the PWM circuit module is used to generate pulse voltages according to the instructions of the main control unit, which are stabilized and smoothed by the filter circuit module and then input to the pulse generation circuit Regulate the voltage of the pulse generating circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com