Electrode plate and preparation method thereof and battery

A technology of electrode sheets and electrode materials, applied in the direction of non-aqueous electrolyte batteries, battery electrodes, lithium batteries, etc., can solve the problem of low charge retention rate, achieve high charge retention rate, good safety, reduce burrs and drop powder effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of the above-mentioned electrode sheet comprises the following steps:

[0044] A protective film is prepared on the current collector and / or the electrode material by using the solution containing the binder or the emulsion containing the binder to obtain an electrode sheet.

[0045]In one of the embodiments, the steps of the preparation method of the above-mentioned electrode sheets include: using a solution containing a binder or an emulsion containing a binder to prepare a protective film on the current collector to obtain a current collector with a protective film; The material is coated, filled or rolled onto a current collector with a protective film to obtain an electrode sheet. That is, the steps of the above-mentioned method for preparing the electrode sheet include step S110 to step S120.

[0046] Step S110 , using a solution containing a binder or an emulsion containing a binder to prepare a protective film on the current collector to ...

Embodiment 1

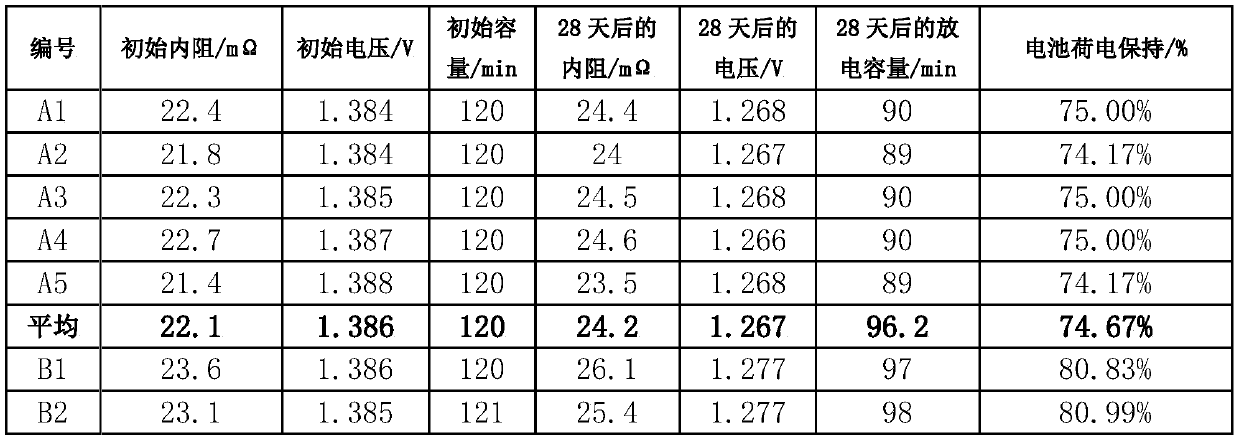

[0070] In Example 1, a total of 5 electrode sheets were prepared, numbered A1 to A5 in sequence, and the preparation method of each electrode sheet is as follows:

[0071] (1) Filling the electrode material into the current collector with permeable pores to obtain a composite body. Wherein, the electrode material is composed of nickelous hydroxide, cobaltous oxide and diytterbium trioxide, and the mass ratio of nickelous hydroxide, cobaltous oxide and diytterbium trioxide is 72.5:5.5:2. Then it is baked and rolled to form an electrode sheet.

[0072] (2) The electrode sheet obtained in step (1) was used as a positive electrode, and a nickel-metal hydride battery was assembled with a separator paper and a negative electrode, and the performance of the battery was measured according to the test method of the charge retention rate, and the results are shown in Table 1. Among them, the specific steps of the test method of charge retention include:

[0073] 1) Discharge the batte...

Embodiment 2

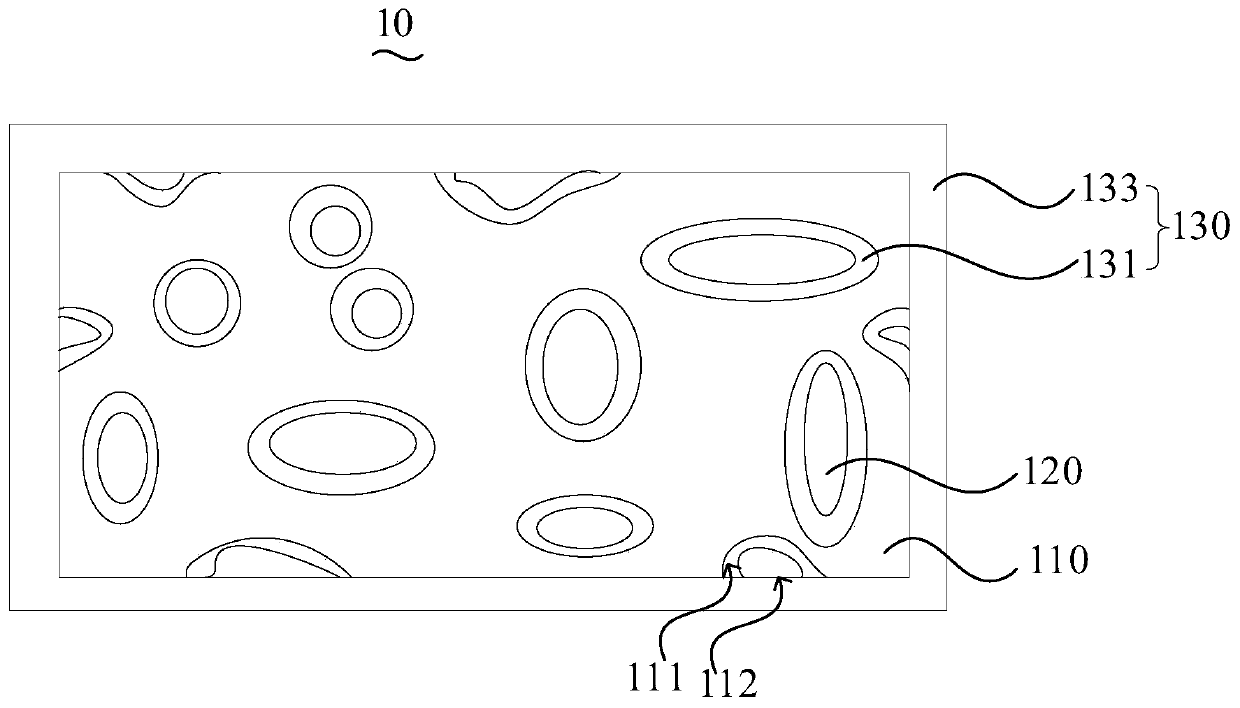

[0080] The structure of the electrode sheet of embodiment 2 is as figure 1 shown. A total of 5 electrode sheets were prepared, numbered B1 to B5 in sequence. The preparation method of each electrode sheet is as follows:

[0081] (1) Dissolve 3g of carboxymethylcellulose (CMC) dry powder in 97mL of pure water, stir at 45°C for 6h, and then cool at room temperature for 36 hours to discharge the air dissolved during the dissolution process to obtain carboxymethylcellulose Solution (hereinafter referred to as CMC solution);

[0082] (2) Pass the CMC solution through the dry compressed air of 4MPa to atomize the CMC solution, and then pass the current collector with permeable holes at a uniform speed through the atomization zone formed by the atomization of the CMC solution, so that the surface of the current collector forms a layer containing CMC membrane. Wherein, the thickness of the interlayer is 0.02mm.

[0083] (3) Filling the electrode material into the current collector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com