High-precision voltage regulation type constant current source system suitable for strong inductive load

A technology of inductive load and constant current source, which is applied in the direction of control system, DC motor speed/torque control, electrical components, etc., can solve the problem of not being able to perfectly adapt to inductive loads, increasing the high-frequency phase shift of the feedback loop, and the accuracy level cannot be achieved Achieve and other problems, achieve the effect of avoiding the reduction of constant current control accuracy, reducing noise crosstalk, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

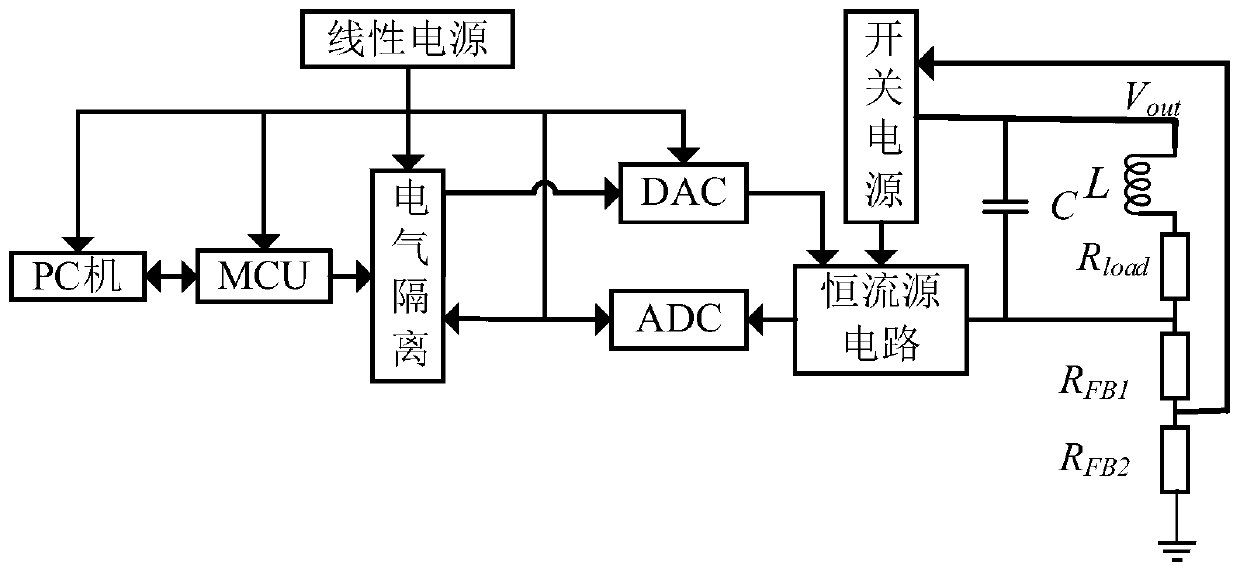

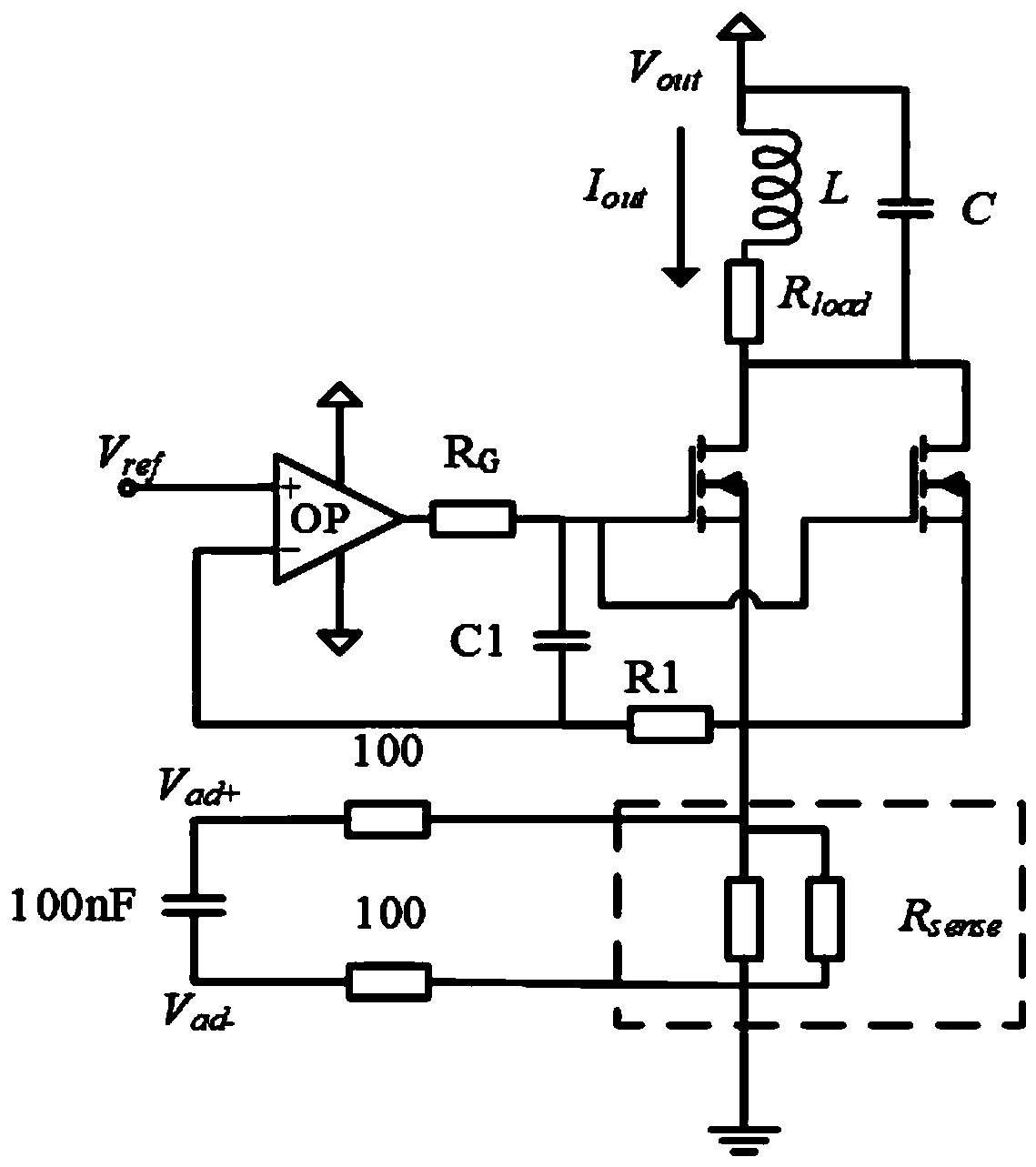

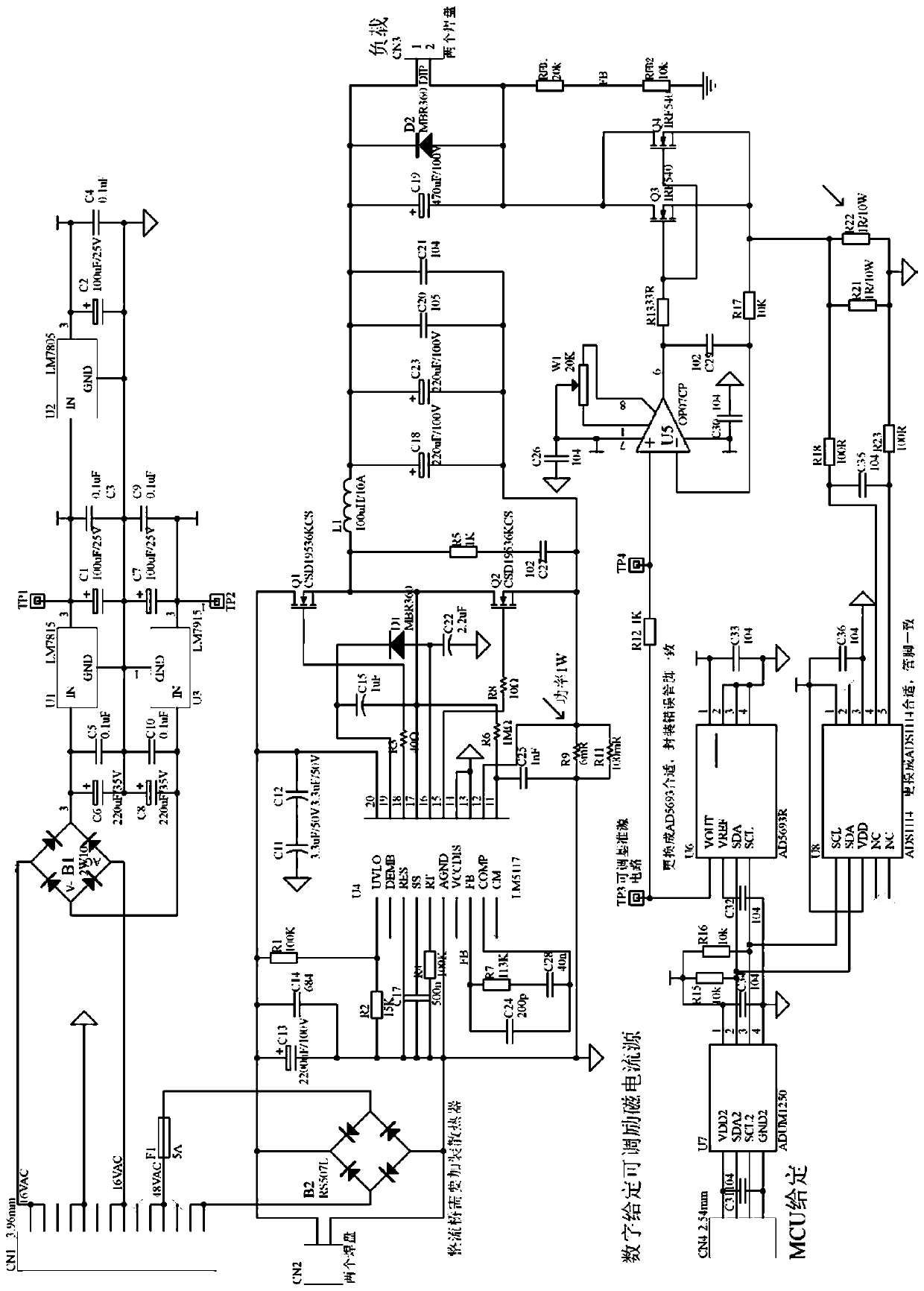

[0029] like Figure 1-5 As shown, the high-precision voltage-regulating constant-current source system suitable for strong inductive loads in this embodiment is based on the voltage-current double-closed-loop voltage-regulating circuit and the technology of adjusting tubes and resistors in parallel, which can make the driving capacity of the constant-current source reach 3A, and the output voltage The maximum to 50V, while the output accuracy of 1%. At the same time, the PCB board area is only 128mm*80mm, and the ampere-level efficiency exceeds 80%. In addition, the parallel compensation capacitor C is used to change the frequency characteristics, solve the problem of self-excited oscillation in strong inductive loads, and improve the phase margin of the constant current source system, thereby improving system stability.

[0030] Including: linear power supply, MCU, electrical isolation module, AD / DA module, switching power supply, constant current source circuit, compensatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com