Optically transparent polymer-based shape memory material and preparation method thereof

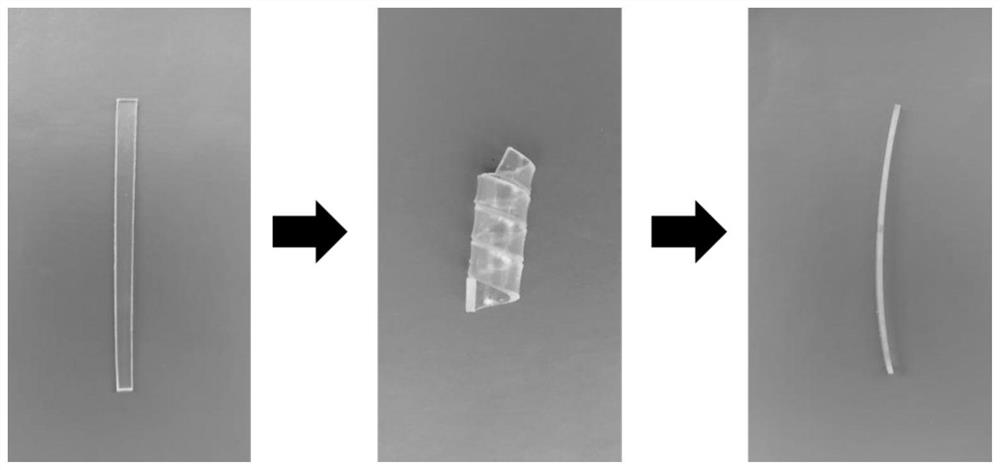

A technology of optically transparent and memory materials, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as poor transparency, and achieve low production costs, simple processes, and excellent shape memory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Use polypropylene carbonate (PPC) (Mw=2.48 x 10 5 g / mol, Boda Dongfang) as the shape memory reversible phase with a refractive index of 1.46; thermoplastic polyurethane elastomer (TPU) (SP9324, BASF) with a Shore hardness of 60A as the shape memory stationary phase with a refractive index of 1.51. Before use, the raw materials were placed in a vacuum oven and dried at 40 °C and 80 °C for 24 h to remove moisture.

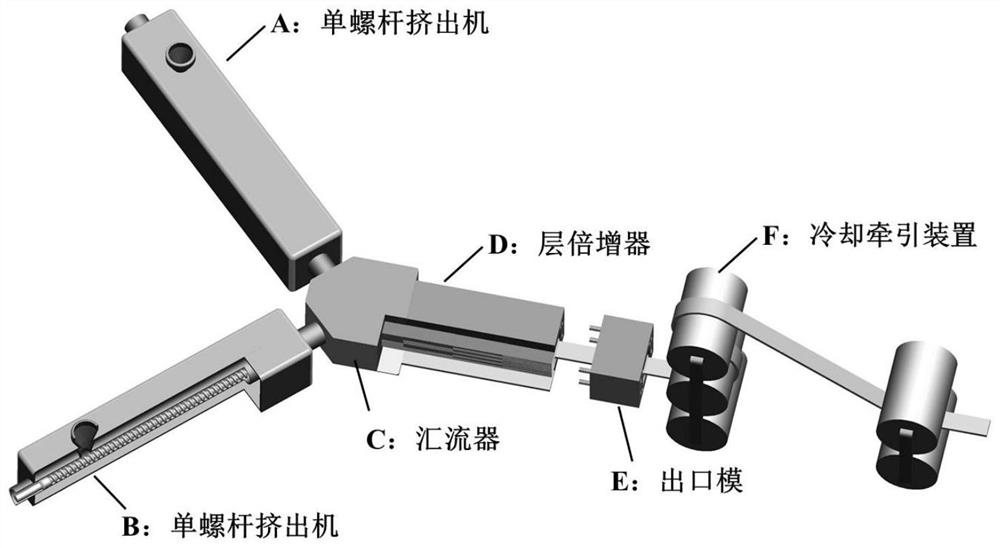

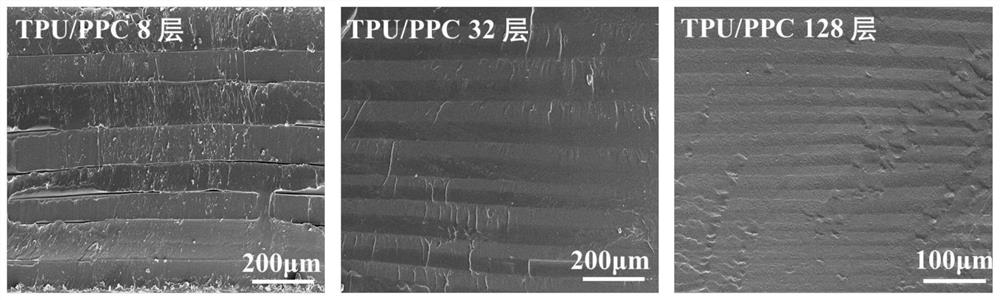

[0032] (2) Put PPC and TPU into two extruders (A, B) of the multi-layer extrusion system respectively (see figure 1), the speed ratio of the extruder is adjusted to 1:1, the temperature of each section of the extruder is controlled at 100-165-160-165°C and 175-185-180-185°C respectively, and the material in the extruder is melted and plasticized Finally, the two melts are superimposed in the confluence C to obtain a two-layer initial structure, and then flow out from the outlet die E of the rectangular flow channel after being sheared and stacked by six ...

Embodiment 2

[0034] (1) Polyvinyl acetate (PVAc) (Vinnapas UW 4fs, WACKER) was selected as the shape memory reversible phase with a refractive index of 1.47; thermoplastic polyurethane elastomer (TPU) (SP9324, BASF) with a Shore hardness of 60A was used as the shape memory Stationary phase with a refractive index of 1.51. Before use, the raw materials were placed in a vacuum oven and dried at 40 °C and 80 °C for 24 h to remove moisture.

[0035] (2) Put PVAc and TPU into two extruders (A, B) of the multi-layer extrusion system respectively (see figure 1 ), the speed ratio of the extruder is adjusted to 1:1, the temperature of each section of the extruder is controlled at 175-185-180-180°C and 185-195-190-185°C respectively, and the material in the extruder is melted and plasticized Finally, the two melts are superimposed in the confluence C to obtain a two-layer initial structure, and then flow out from the outlet die E of the rectangular flow channel after being sheared and stacked by si...

Embodiment 3

[0037] (1) Polylactic acid (PLA) (4032D, Natureworks Corp) was selected as the shape memory reversible phase with a refractive index of 1.45; thermoplastic polyamide elastomer (TPAE) (8211-70, DuPont) was used as the shape memory stationary phase with a refractive index of 1.5. The raw materials were dried in a vacuum oven at 80 °C for 24 h to remove moisture before use.

[0038] (2) Put PLA and TPAE into two extruders (A, B) of the multi-layer extrusion system respectively (see figure 1 ), the speed ratio of the extruder is adjusted to 1:1, the temperature of each section of the extruder is controlled at 100-180-175-180°C and 175-185-180-185°C respectively, and the material in the extruder is melted and plasticized Finally, the two melts are superimposed in the confluence C to obtain a two-layer initial structure, and then flow out from the outlet die E of the rectangular flow channel after being cut and stacked by nine layer multipliers D, where the confluence C The temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com