Deep-fried puffed food taking polished round-grained rice as raw material

A technology for deep-fried puffed and japonica rice, which is used in food ingredients as taste improvers, food science and other directions, can solve the problems of the same taste and taste, few types of consumers, and high prices, and achieves less moldy particles and impurities. The effect of less good products and less oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

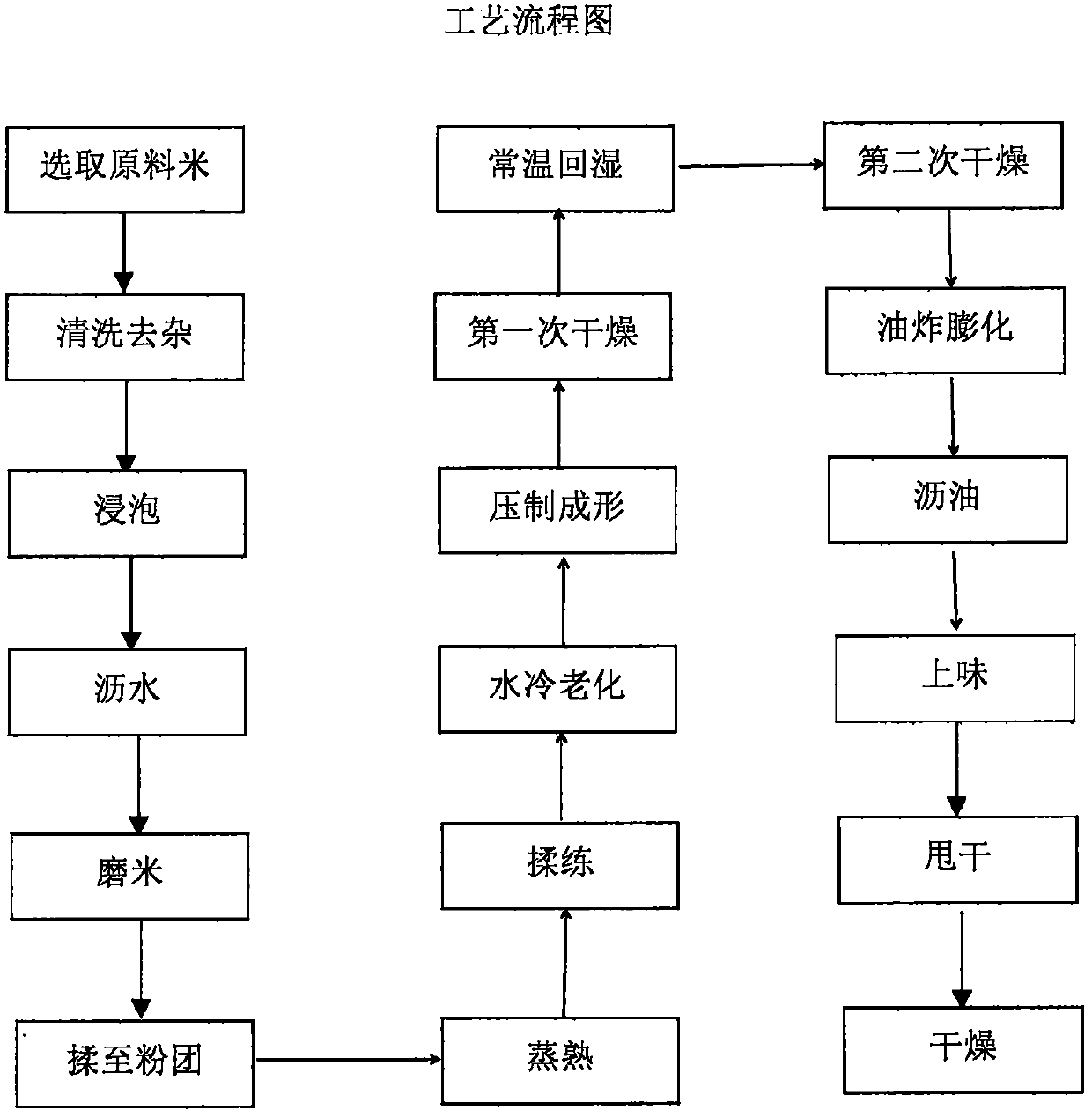

[0029] (1) Combined process flow chart figure 1 Embodiments are described.

[0030] (1) Select the japonica rice of the current year, wash and remove impurities.

[0031] (2) Soaking: use normal temperature water, soaking time is 6-7 hours in summer and 9-10 hours in winter. The water content is about 35%.

[0032] (3) Drain water: pour the soaked japonica rice into the wire mesh to drain water for about 1 hour, with a water content of about 25%.

[0033] (4) Grinding: the japonica rice is ground into a fineness of 80-100 mesh by rolling method, and the particle size is uniform.

[0034] (5) Knead the dough: add boiled water and rice flour, and knead fully, so that the rice flour has even water content and no dry rice flour is mixed.

[0035] (6) Steaming: Steam the rice noodles in a steamer for 70 minutes to gelatinize the rice noodles.

[0036] (7) Water-cooled aging: After the gelatinized dough is kneaded in a dough kneader, it is cooled in a 40° water tank to age the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com