Large-flow flat plate organic waste gas plasma treatment device

A technology of organic waste gas and plasma, applied in gas treatment, separation methods, and separation of dispersed particles, etc., can solve problems such as insufficient mixing of arc discharge and air flow, small discharge plasma area, and uneven distribution of arc discharge space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

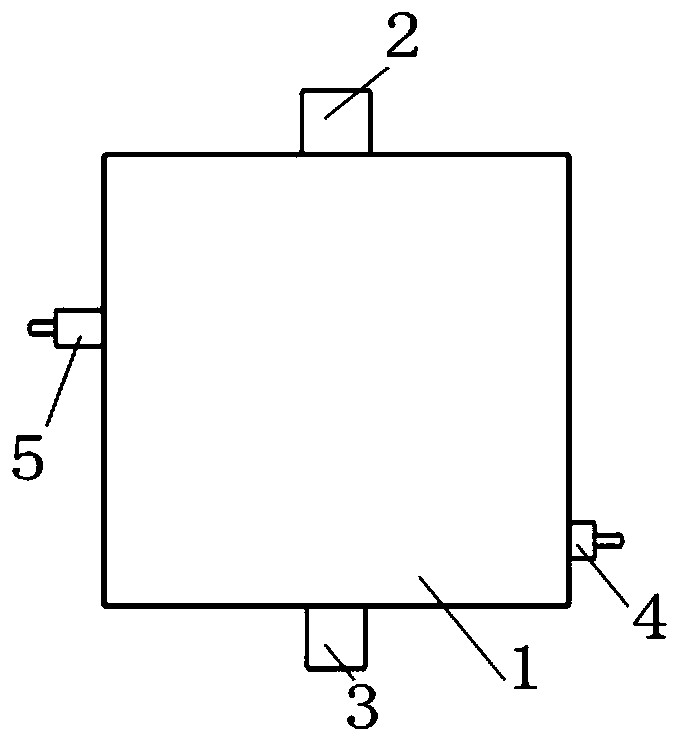

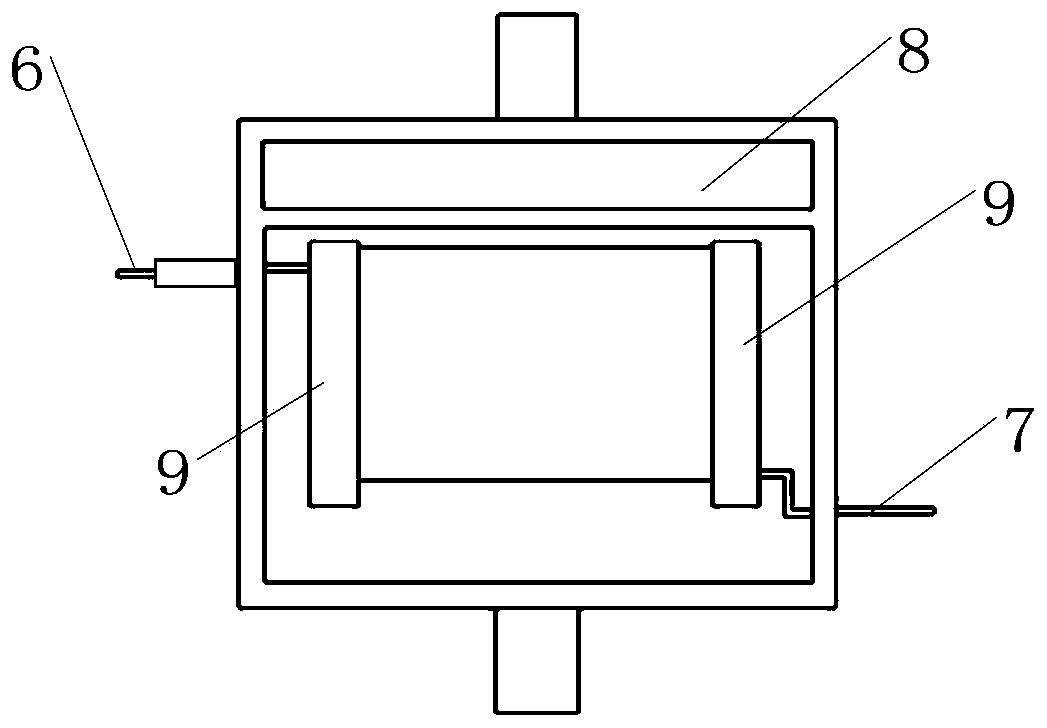

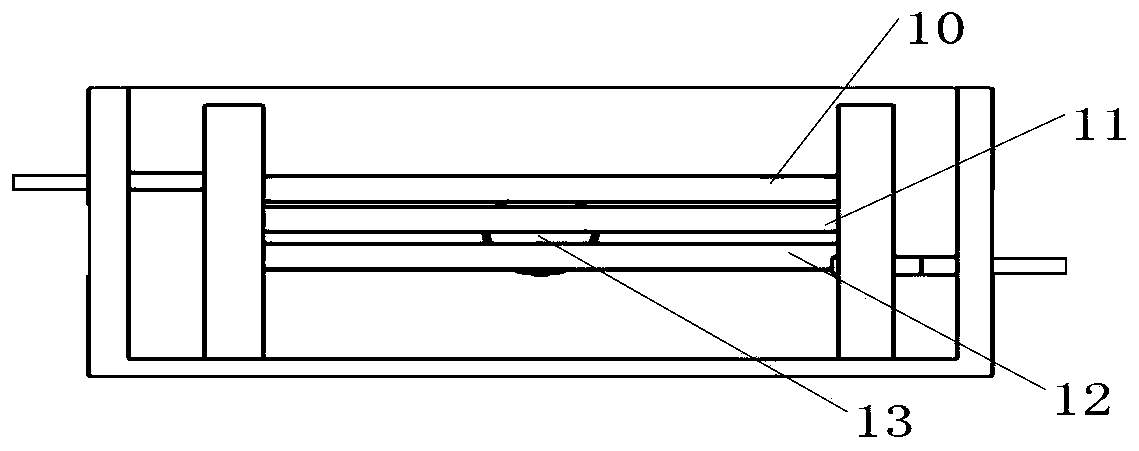

[0019] The present invention as figure 1 , figure 2 , image 3 As shown, it is a large-flow flat-plate organic waste gas plasma treatment device including a shell 1, an air inlet pipe 2, an air outlet pipe 3, a grounding sheath 4, a high-voltage electrode sheath 5, a high-voltage electrode 6, a grounding electrode 7, and a gas buffer chamber 8 , bracket 9, electrode grid 10, quartz plate 11, grounding grid 12, through hole 13, air inlet pipe 2 is connected with shell 1, air outlet pipe 3 is connected with shell 1, grounding sheath 4 is connected with shell 1, high voltage electrode sheath 5 It is connected with the shell 1, the air inlet pipe 2 and the through hole 13 are connected with the gas buffer chamber 8, the high voltage electrode 6 is connected with the high voltage electrode sheath 5, the ground electrode 7 is connected with the ground sheath 4, the electrode net 10 is connected with the high voltage electrode 6, The grounding grid 12 is connected to the grounding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com