Cleaning fluorinated surface inside ion implanter

An implanter and ion technology, applied in the direction of cleaning methods and appliances, chemical instruments and methods, discharge tubes, etc., can solve the problems of short effective time, limited effect, and multiple downtime, so as to reduce downtime and processing time , the effect of benefit enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

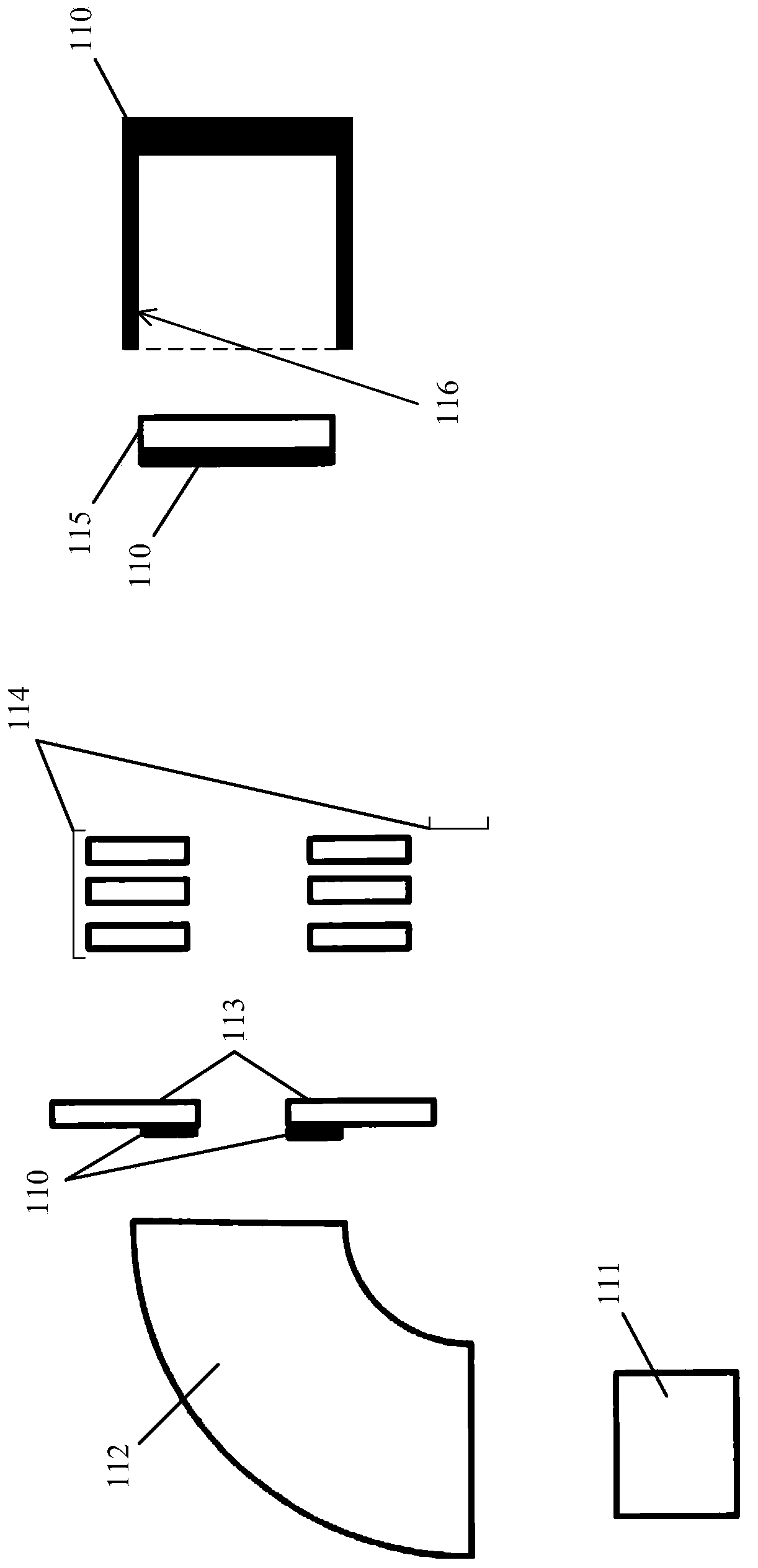

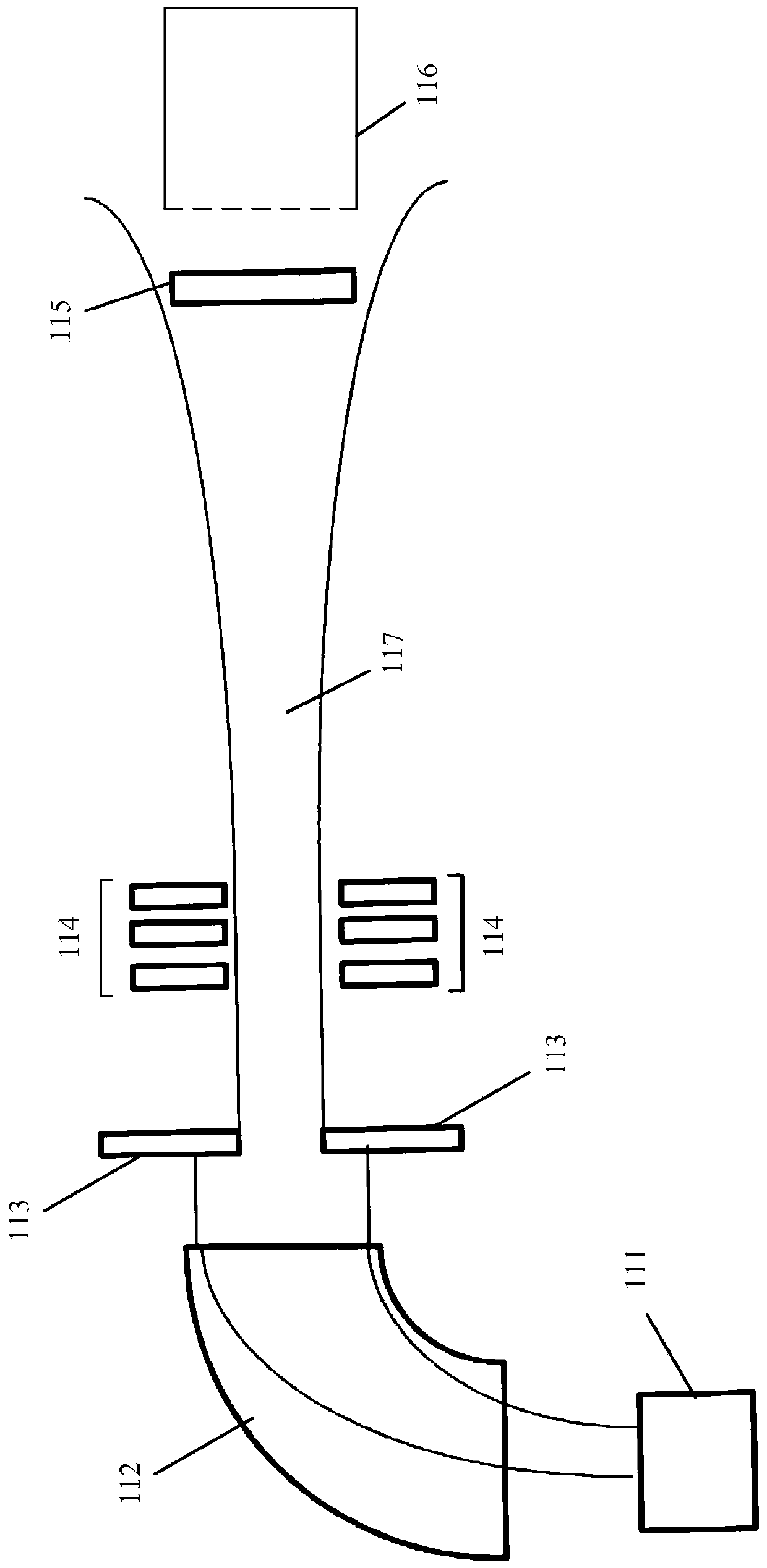

[0057] Embodiments are described herein that can clean fluorinated surfaces on internal components of an ion implanter. Some embodiments relate to the use of hydrogen-containing ion beams or boron-containing ion beams, some embodiments relate to the use of plasma guns or other sources of hydrogen-containing particles, some embodiments relate to the use of heaters (or even coolers), and others Relate to any combination of the previous embodiments. Thereby, fluorinated material formed on the internal components can be removed such that the fluorinated surface can be cleaned.

[0058] Some embodiments use a hydrogen-containing ion beam having a large number of hydrogen-containing ions (or hydrogen-containing particles) to clean fluorinated surfaces previously formed by ion implantation using a fluorine-containing ion beam. Reasonably, implementation of these embodiments does not require modification of the configuration of the ion implanter, since the same ion beam source can su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com