Solid rocket motor combustor insulation layer injection or injection molding tooling and its process

A solid rocket and injection molding technology, applied in the direction of coating, etc., can solve the problems of low accuracy of shape and size, difficult operation of size and structure, and low pass rate at one time, and achieve high quality consistency, high stability and dimensional accuracy High, fast glue injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

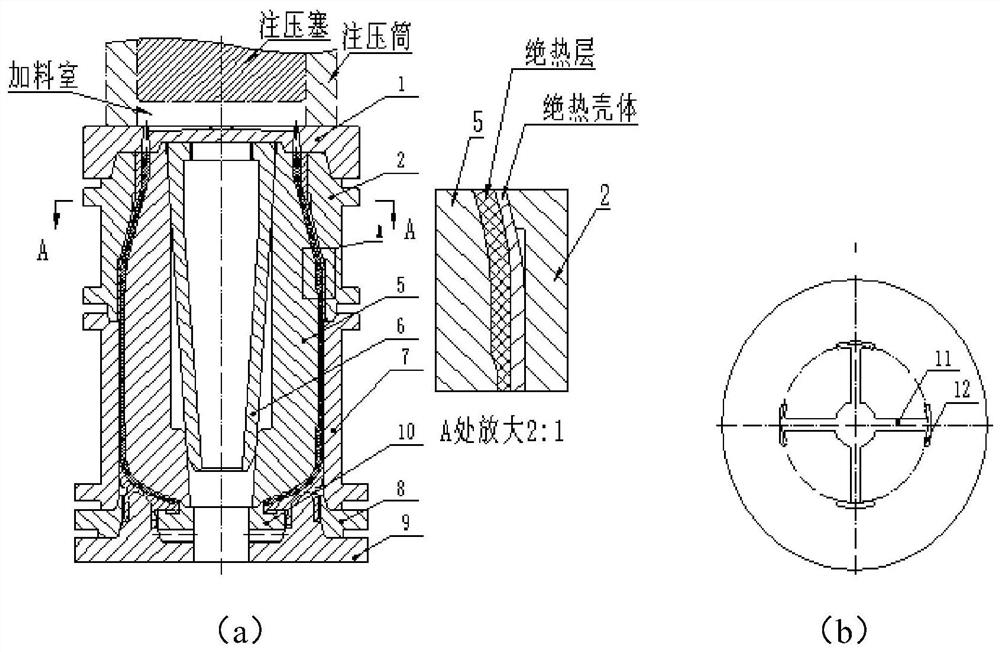

[0041] When the insulating casing is vertical, the structure of the injection molding tooling for the thermal insulation layer of the solid rocket motor combustion chamber is as follows: figure 1 As shown in (a), it includes a pouring integrated plate 1, a heat-insulating shell pressure-bearing limit assembly, a split-type combined mold core 5, a limit cone 6, and a heat-insulating shell. The detailed design of each part is as follows:

[0042] The pressure-bearing limit assembly of the heat-insulated shell is used to provide pressure-bearing support for the outside of the heat-insulated shell during the process of injecting or pressing the heat-insulating material inside the heat-insulated shell; it includes a plurality of heat-insulated shell limit pressure-bearing blocks 2, 7, 8, 9, 10, the inner side of these limit bearing blocks of the heat insulating shell are sintered with polytetrafluoroethylene coating, the thickness of the polytetrafluoroethylene coating is 0.05mm ~ 0...

Embodiment 2

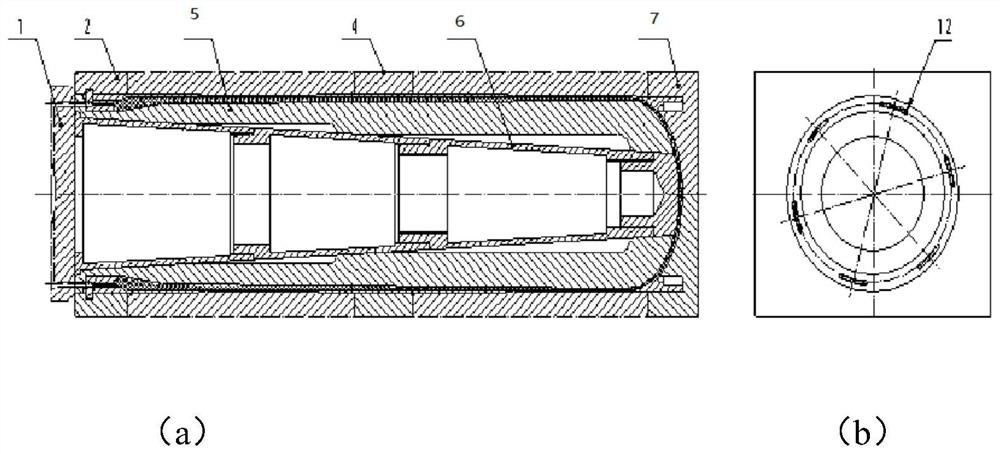

[0048] When the heat insulation casing is horizontal, the structure of the injection molding tooling for the heat insulation layer of the solid rocket motor combustor is as follows: figure 2 As shown in (a), it is basically the same as that of Embodiment 1. The pouring integrated board 1 is on the side of the heat-insulating shell. From the left sectional view, the distribution of the runners 12 on the pouring integrated board 1 is as follows figure 2 As shown in (b), a plurality of heat-insulating shell space-limiting pressure-bearing blocks 2, 4, 7 of the heat-insulating shell pressure-limiting assembly protect the heat-insulating shell from the periphery; From the port on one side of the heat-insulating shell, enter the cavity inside the heat-insulating shell where the molding and the heat-insulating shell form an insulating layer.

[0049] The molding process adopts a high-pressure injection method, and the heat-insulating material is injected into the cavity between the...

Embodiment 3

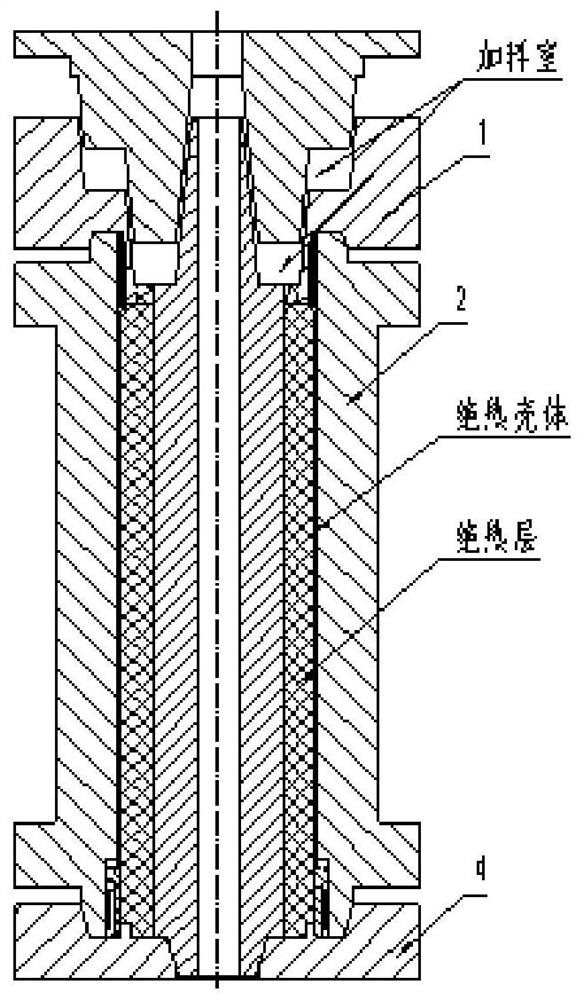

[0051] When the heat insulation shell is a vertical heat insulation shell with its own feeding chamber, the structure of the injection molding tooling for the heat insulation layer of the solid rocket motor combustion chamber is as follows: image 3 As shown, it is basically the same as Example 1, the difference is that the tooling mold has its own feeding chamber, which can be implemented when there is no pressurization or injection function on the equipment, and is generally suitable for heat insulation of small or micro engines

[0052] The molding process adopts the injection pressure method, and the heat insulating material is injected into the cavity between the heat insulating shell and the split-type combined mold core 5 with a pressure of 3Mpa-20MPa. The schematic diagram of the heat insulating material formed in the heat insulating shell is as follows: Figure 8 shown.

[0053] In the above-mentioned examples 1-3, in order to ensure that compared with ordinary rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com