A seawater evaporation desalination membrane material, its preparation method and application

A seawater evaporation and desalination membrane technology, which is applied in the field of membrane materials, can solve the problems of complex and no bacteria inhibition, and achieve high retention rate, good antibacterial property, and less time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

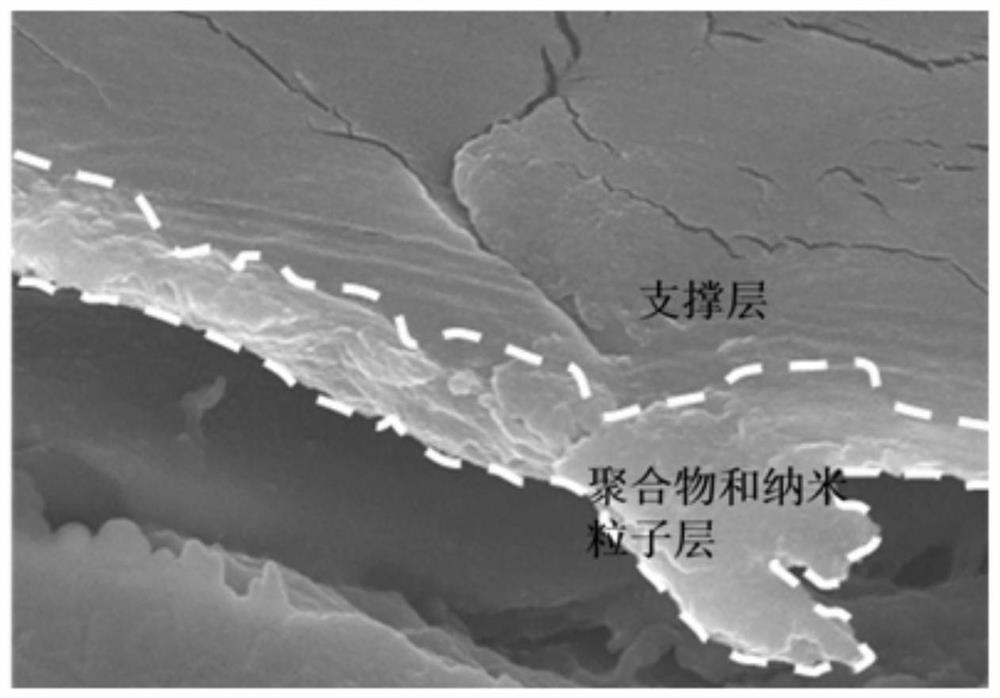

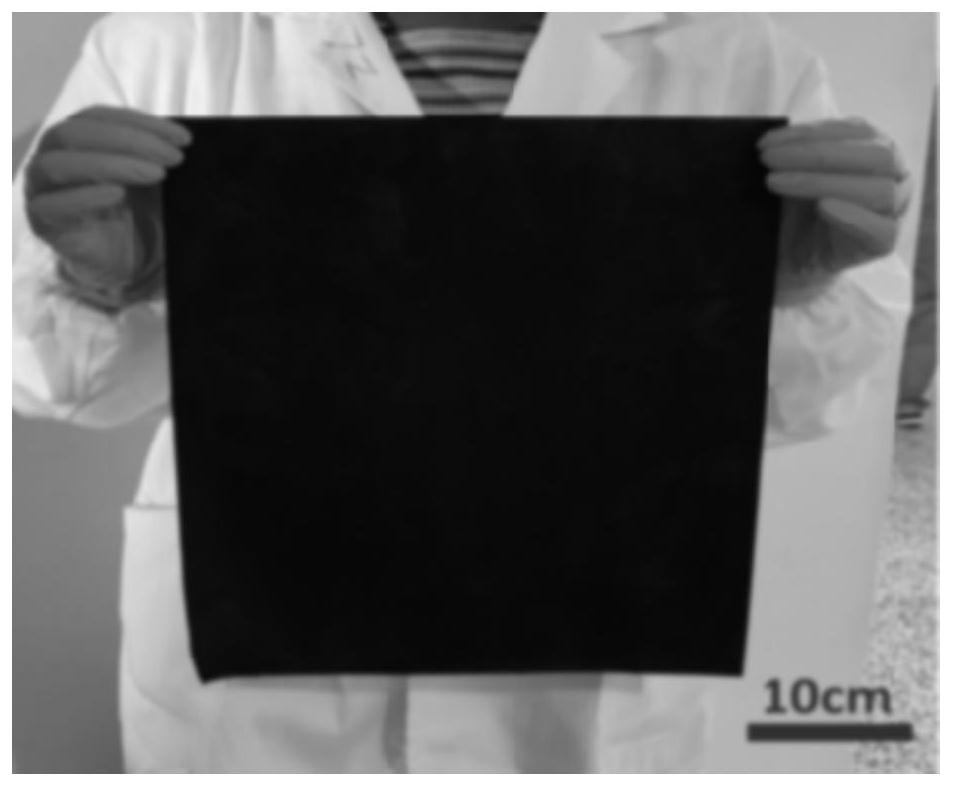

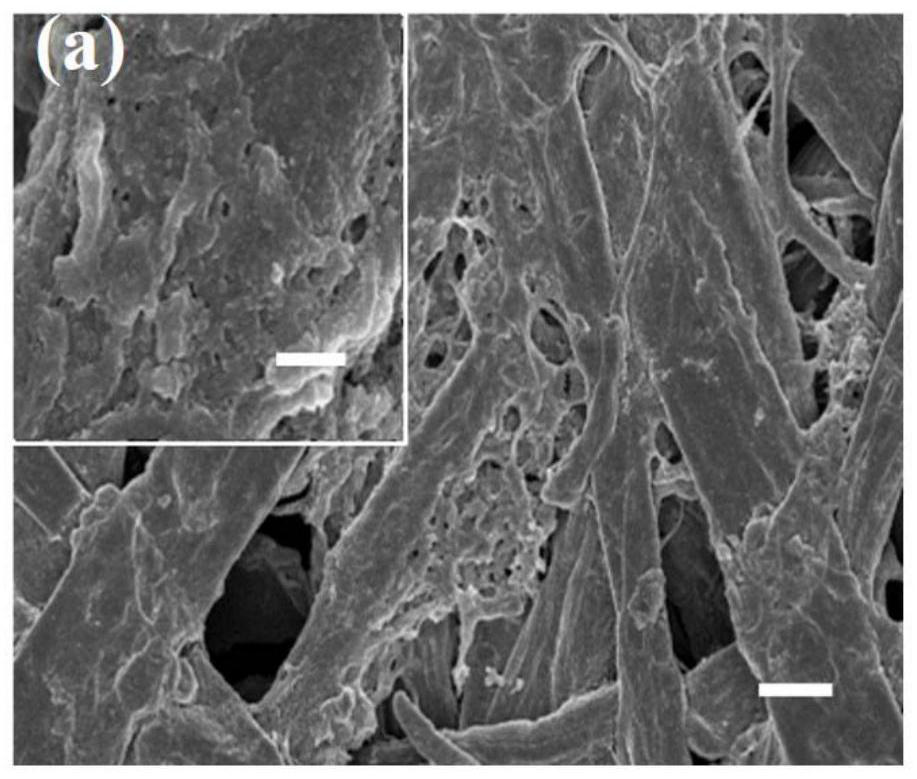

Image

Examples

preparation example Construction

[0069] Further, the concentration of the solution of the oxidant is 1~10mg / mL.

[0070] Further, the immersion time is 0.5 to 2h, and the immersion temperature is 0 to 20°C.

[0071] Further, the drying temperature is 10~40 ℃, and the time is 1~3h.

[0073] Further, the temperature of the impregnation is 10 ~ 50 ℃, and the time is 5 ~ 20h.

[0074] Further, the drying temperature is 20 ~ 45 ° C, and the time is 0.5 ~ 3h.

[0076] Further, the concentration of the nanoparticle material solution is 0.01 to 0.08 mol / L.

[0077] Further, the temperature of the polymerization reaction is 30~90 ℃, and the time is 5~50min.

[0078] Further, the drying temperature is 10~60 ℃, and the time is 10~40min.

Embodiment 1

Embodiment 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com