A multi-station combined treatment system and method for oil field reinjection water

An oilfield water reinjection and combined treatment technology, applied in mining wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc. The effects of inhibiting new precipitation and coalescence growth, stable water quality and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and embodiments.

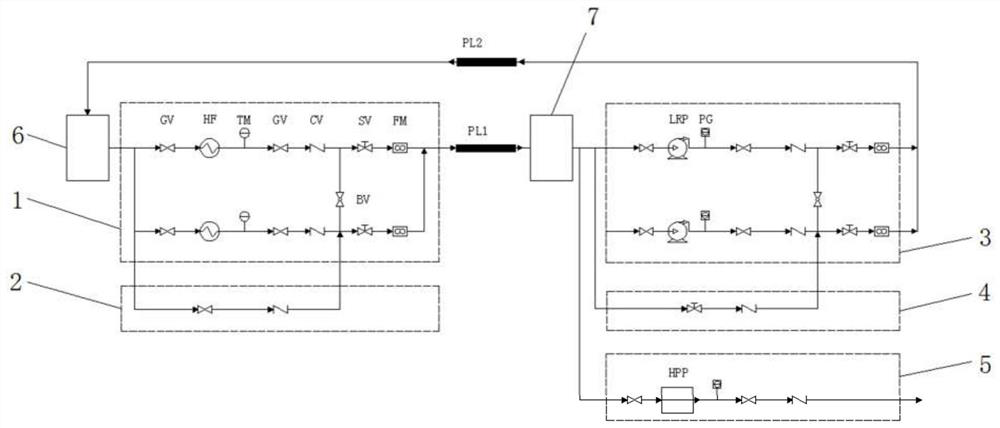

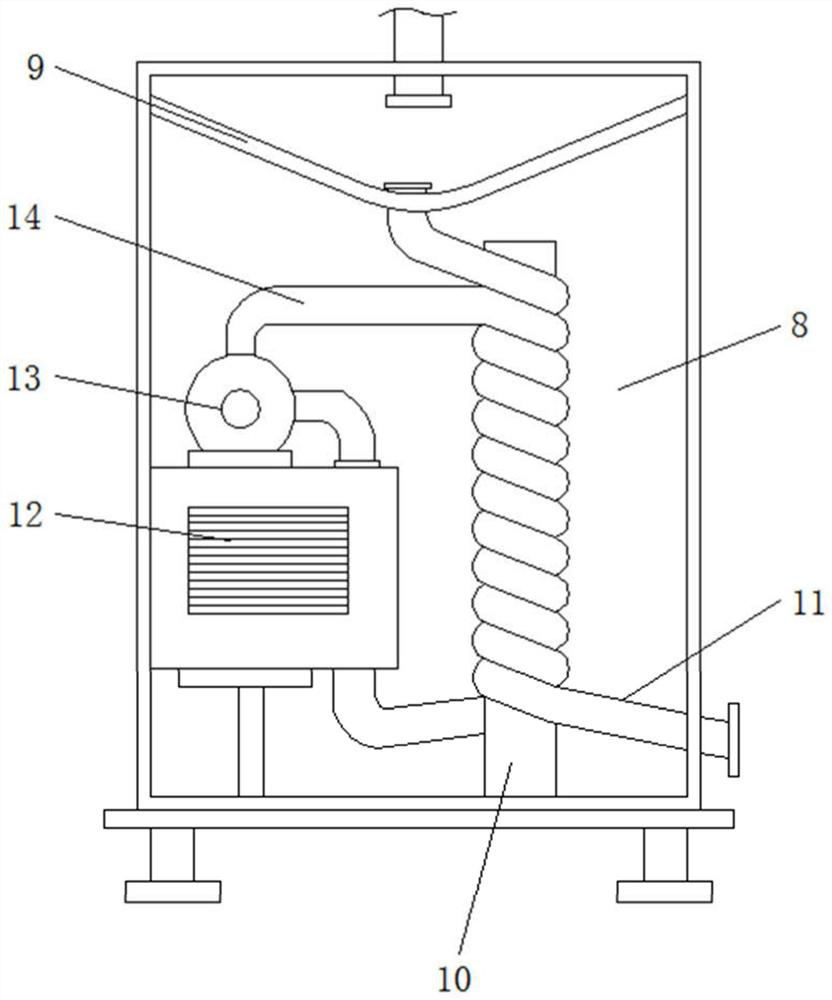

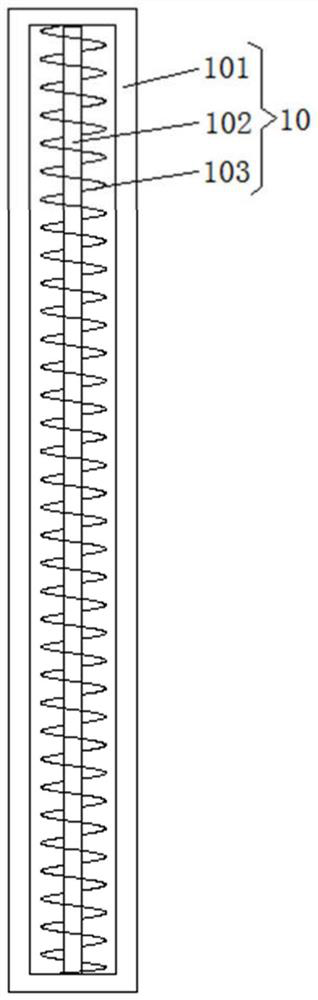

[0033] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 It is a schematic structural diagram of a preferred embodiment of the multi-station combined treatment system for oil field re-injection water provided by the present invention; figure 2 A schematic structural diagram of the heating furnace provided by the present invention; image 3 for figure 2 A structural cross-sectional view of the heating structure shown. The oilfield reinjection water multi-station combined treatment system and method include:

[0034] Back-injection water heating device 1, back-injection water heating bypass device 2, water-injection station back-injection water return device 3, back-injection water return-transport bypass device 4, back-injection water injection into formation device 5, combined station 6 and water injection station 7;

[0035] One si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com