Preparation method of full-flexible tensile sensor suitable for 3D printing

A 3D printing, flexible and conductive technology, applied in 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problems of low flexibility, no sensor stability, human injury, etc., to improve service life, good electricity Effects on Response Performance and Lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The liquid conductive rubber formula is 63wt% liquid silicone rubber, 27wt% silver-plated glass fiber (18wt% silver plating, aspect ratio 200μm:8μm), 4wt% carbon fiber, 4wt% 1,2 propylene glycol, 2wt% simethicone. Prepare according to the following steps: ① Mixing, add the prepared materials in order of liquid silicone rubber, silver-plated glass fiber, carbon fiber, 1,2 propylene glycol and simethicone oil and mix evenly; ② Degassing canned : Inject the mixed liquid conductive rubber into the printing syringe after vacuum degassing, and degassing again after injection; ③Print and shape, the inner diameter of the extrusion needle is 0.42mm, the pressure is 0.5MPa, the printing speed is 8cm / s; the embedding depth is 0.3mm; ④ Curing, curing temperature 120 ℃, 10min.

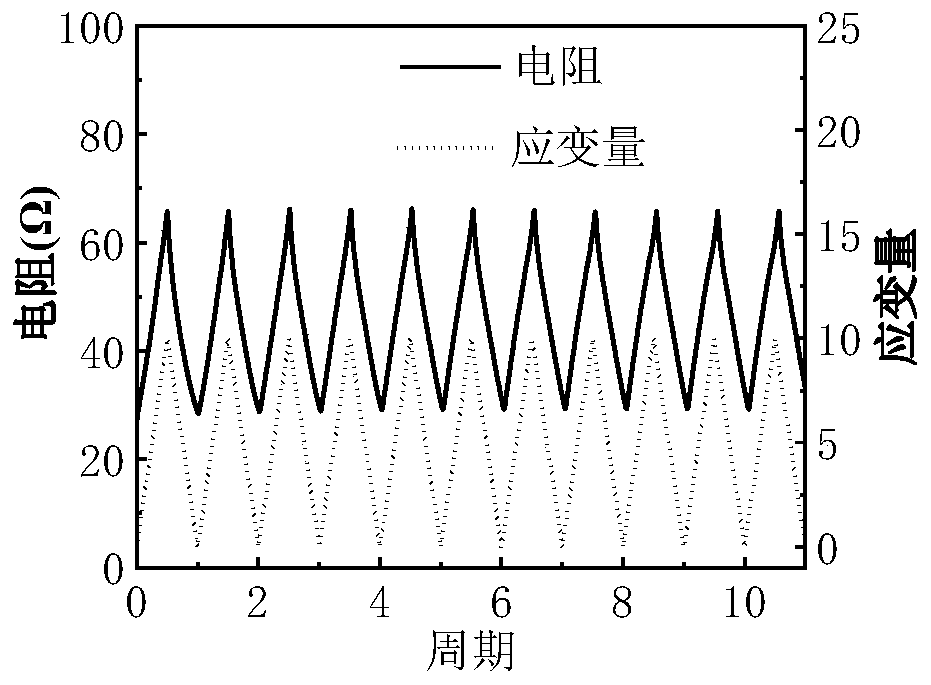

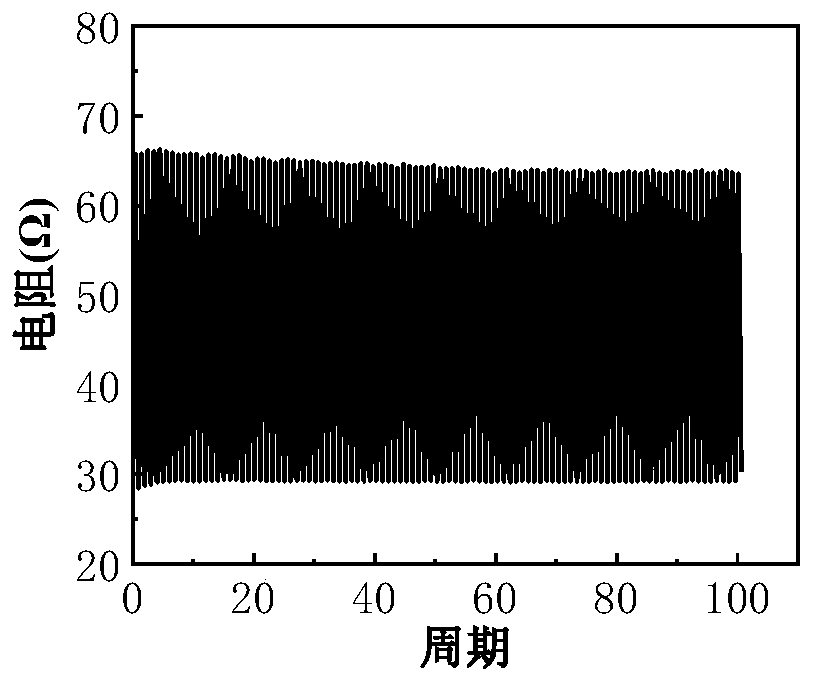

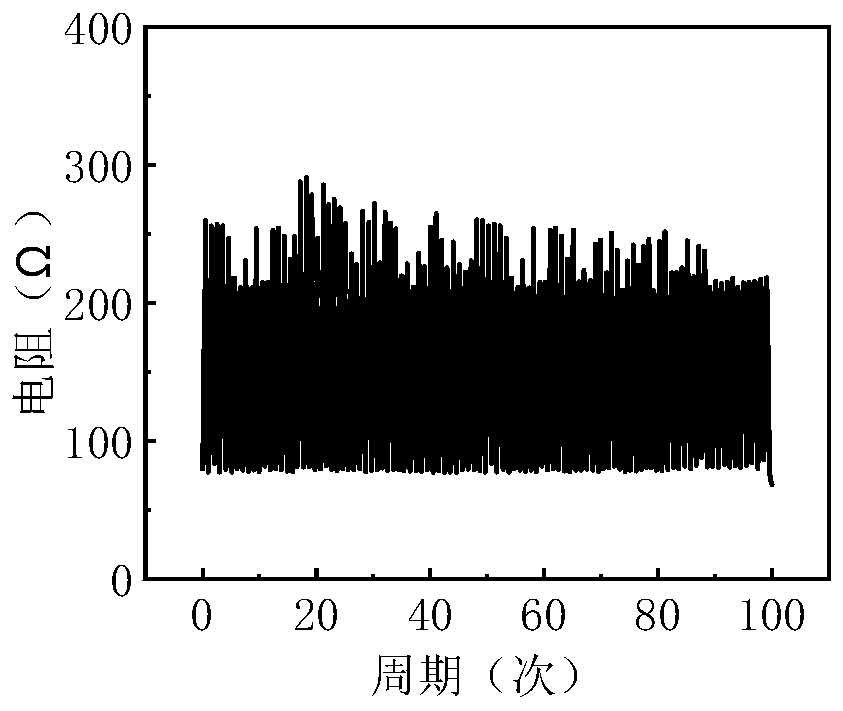

[0040] The finished product has a volume resistivity of 0.085Ω·cm, a tensile strength of 3.1MPa, an elongation at break of 265%, a sensitivity (resistance change rate / strain) of 17, and stable performance wi...

Embodiment 2

[0042] The liquid conductive rubber formula is 60wt% liquid silicone rubber, 32wt% silver-plated glass fiber (silver plating amount 18wt% aspect ratio 200μm: 8μm), 3wt% carbon fiber, 3wt% 1,2 propylene glycol, 2wt% simethicone. Prepare according to the following steps: ① Mixing, add the prepared materials in order of liquid silicone rubber, silver-plated glass fiber, carbon fiber, 1,2 propylene glycol and simethicone oil and mix evenly; ② Degassing canned : Inject the mixed liquid conductive rubber into the printing syringe after vacuum degassing, and degassing again after injection; ③Print and shape, the inner diameter of the extrusion needle is 0.42mm, the pressure is 0.5MPa, the printing speed is 8cm / s; the embedding depth is 0.3mm; ④ Curing, curing temperature 120 ℃, 10min.

[0043] The finished product has a volume resistivity of 0.021Ω·cm, a tensile strength of 2.6MPa, an elongation at break of 243%, a sensitivity (resistance change rate / strain amount) of 14, and stable ...

Embodiment 3

[0045] The liquid conductive rubber formula is 55wt% liquid silicone rubber, 35wt% silver-plated glass fiber (silver plating amount 18wt% aspect ratio 200μm: 8μm), 3wt% carbon fiber, 3wt% 1,2 propylene glycol, 4wt% thinner. Prepare according to the following steps: ① Mixing, add the prepared materials in order of liquid silicone rubber, silver-plated glass fiber, carbon fiber, 1,2 propylene glycol and simethicone oil and mix evenly; ② Degassing canned : Inject the mixed liquid conductive rubber into the printing syringe after vacuum degassing, and degassing again after injection; ③Print and shape, the inner diameter of the extrusion needle is 0.42mm, the pressure is 0.5MPa, the printing speed is 8cm / s; the embedding depth is 0.3mm; ④ Curing, curing temperature 120 ℃, 10min.

[0046] The finished product has a volume resistivity of 0.009Ω·cm, a tensile strength of 2.4MPa, an elongation at break of 232%, a sensitivity (resistance change rate / strain amount) of 11, and stable perf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com