A kind of gelatin-based food packaging film and preparation method thereof

A food packaging film and gelatin-based technology, which is applied in the field of packaging materials, can solve the problems of low thermal stability and physical and mechanical properties of gelatin-based film materials, and cannot be completely replaced, and is conducive to large-scale industrial production and has excellent physical and mechanical properties. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

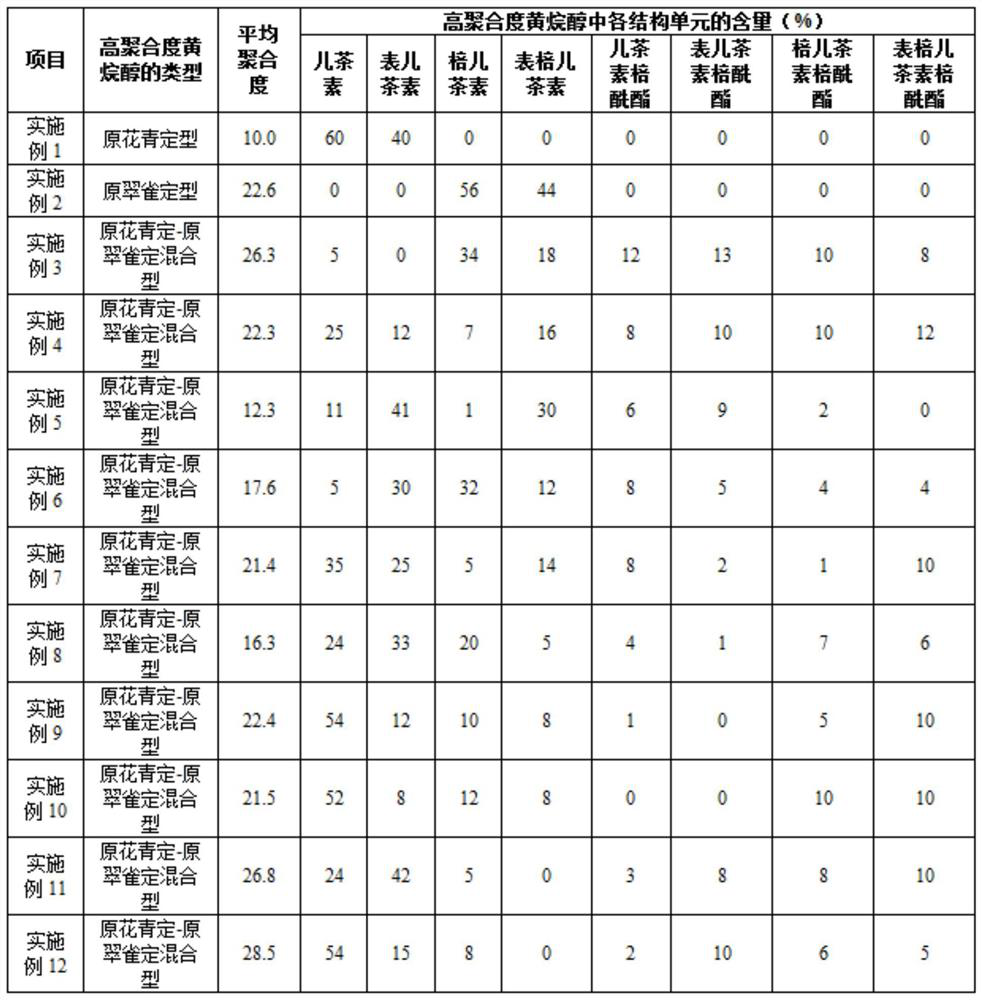

Embodiment 1

[0020] A preparation method of a gelatin-based food packaging film, which comprises the following processing steps:

[0021] 1) Mix and soak 16 parts of gelatin and 100 parts of distilled water according to the mass parts of raw materials for 1 hour, raise the temperature to 50°C and let stand for 30 minutes to obtain a gelatin matrix;

[0022] 2) 20 parts of Ti with a concentration of 4g / L 2 (SO 4 ) 3 Add the aqueous solution to the gelatin matrix, stir for 20min, then add 20 parts of high-polymerization degree flavanol aqueous solution with a concentration of 0.8g / L, stir for 10min, then add 5 parts of sodium hydroxide aqueous solution with a concentration of 0.16mol / L and 5 Parts of glycerin were cast into a film, and dried at 50°C for 12 hours to obtain the finished product of Example 1.

Embodiment 2

[0024] A preparation method of a gelatin-based food packaging film, which comprises the following processing steps:

[0025] 1) Mix and soak 25 parts of gelatin and 100 parts of distilled water according to the mass parts of raw materials for 1 hour, raise the temperature to 50°C and let stand for 30 minutes to obtain a gelatin matrix;

[0026] 2) 20 parts of TiO with a concentration of 3g / L 2 Add the aqueous solution to the gelatin matrix, stir for 20min, then add 15 parts of high-polymerization degree flavanol aqueous solution with a concentration of 0.6g / L, stir for 10min, then add 5 parts of sodium hydroxide aqueous solution with a concentration of 0.1mol / L and 5 Parts of glycerin were cast into a film, and dried at 50°C for 12 hours to obtain the finished product of Example 2.

Embodiment 3

[0028] A preparation method of a gelatin-based food packaging film, which comprises the following processing steps:

[0029] 1) Mix and soak 20 parts of gelatin and 100 parts of distilled water according to the mass parts of raw materials for 1.5 hours, raise the temperature to 50°C and let stand for 40 minutes to obtain a gelatin matrix;

[0030] 2) 25 parts of Ti with a concentration of 6g / L 2 (SO 4 ) 3 Add the aqueous solution to the gelatin matrix, stir for 10 minutes, then add 20 parts of high-polymerization degree flavanol aqueous solution with a concentration of 0.5 g / L, stir for 15 minutes, then add 6 parts of sodium hydroxide aqueous solution with a concentration of 1.2 mol / L and 3 Parts of glycerin were cast into a film, and dried at 60°C for 10 hours to obtain the finished product of Example 3.

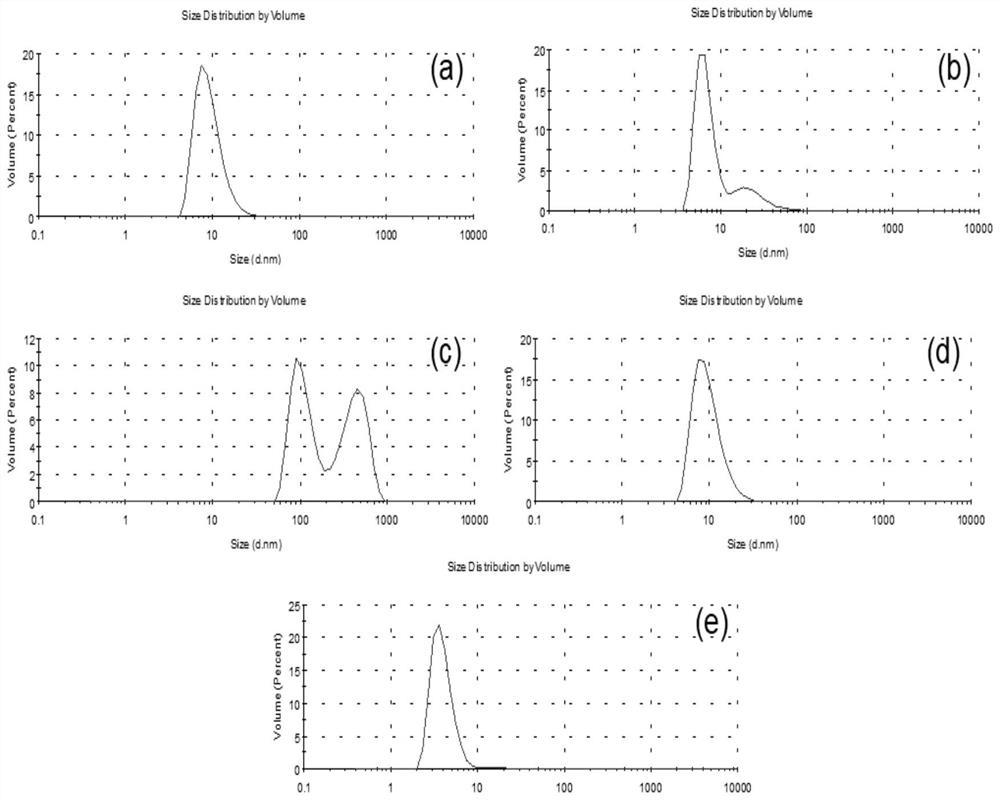

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com