Household garbage gasification treatment system with chlorine removal function

A domestic garbage and treatment system technology, which is applied in the gasification of granular/powdered fuels, the manufacture of combustible gases, and the petroleum industry. zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

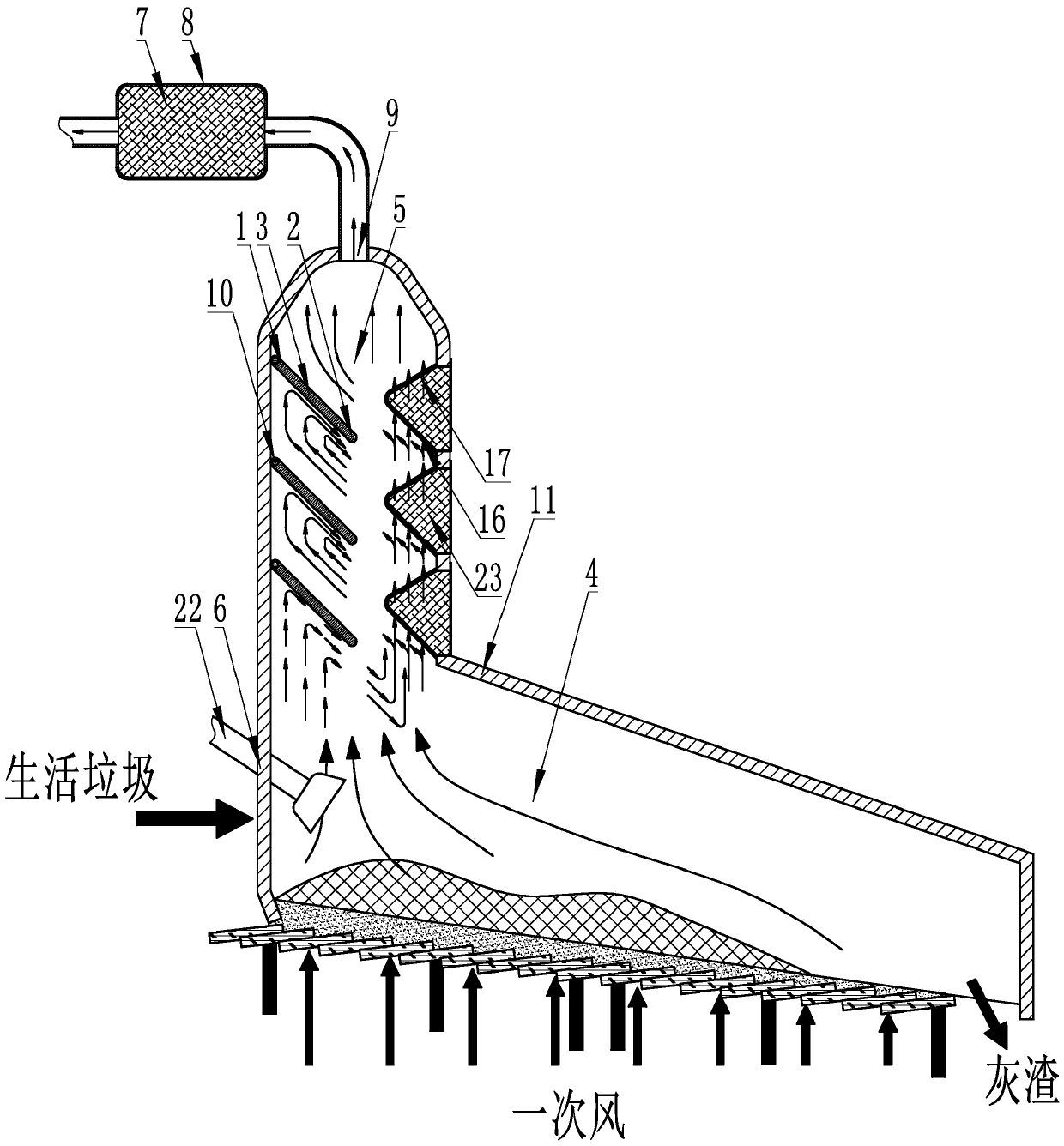

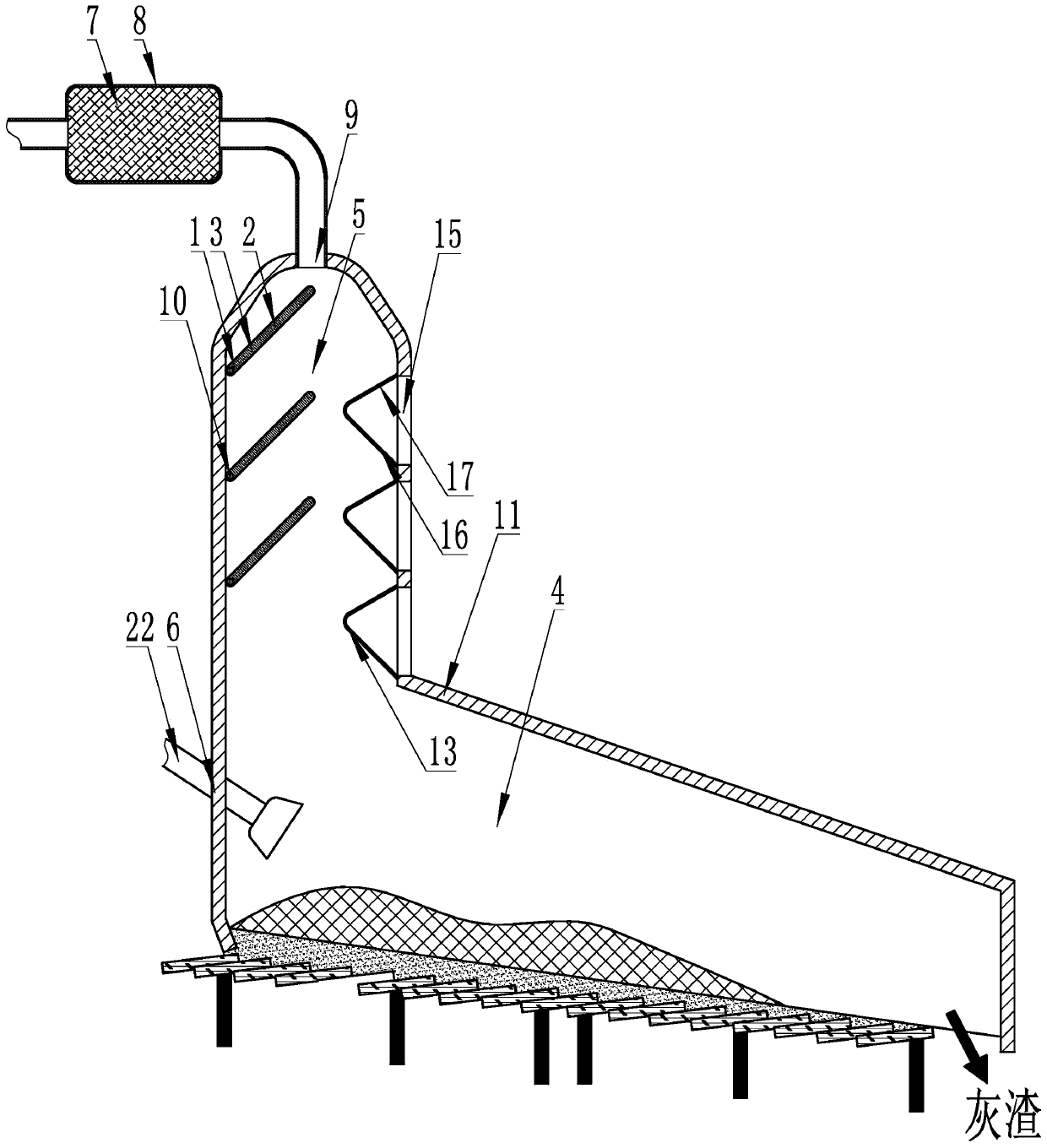

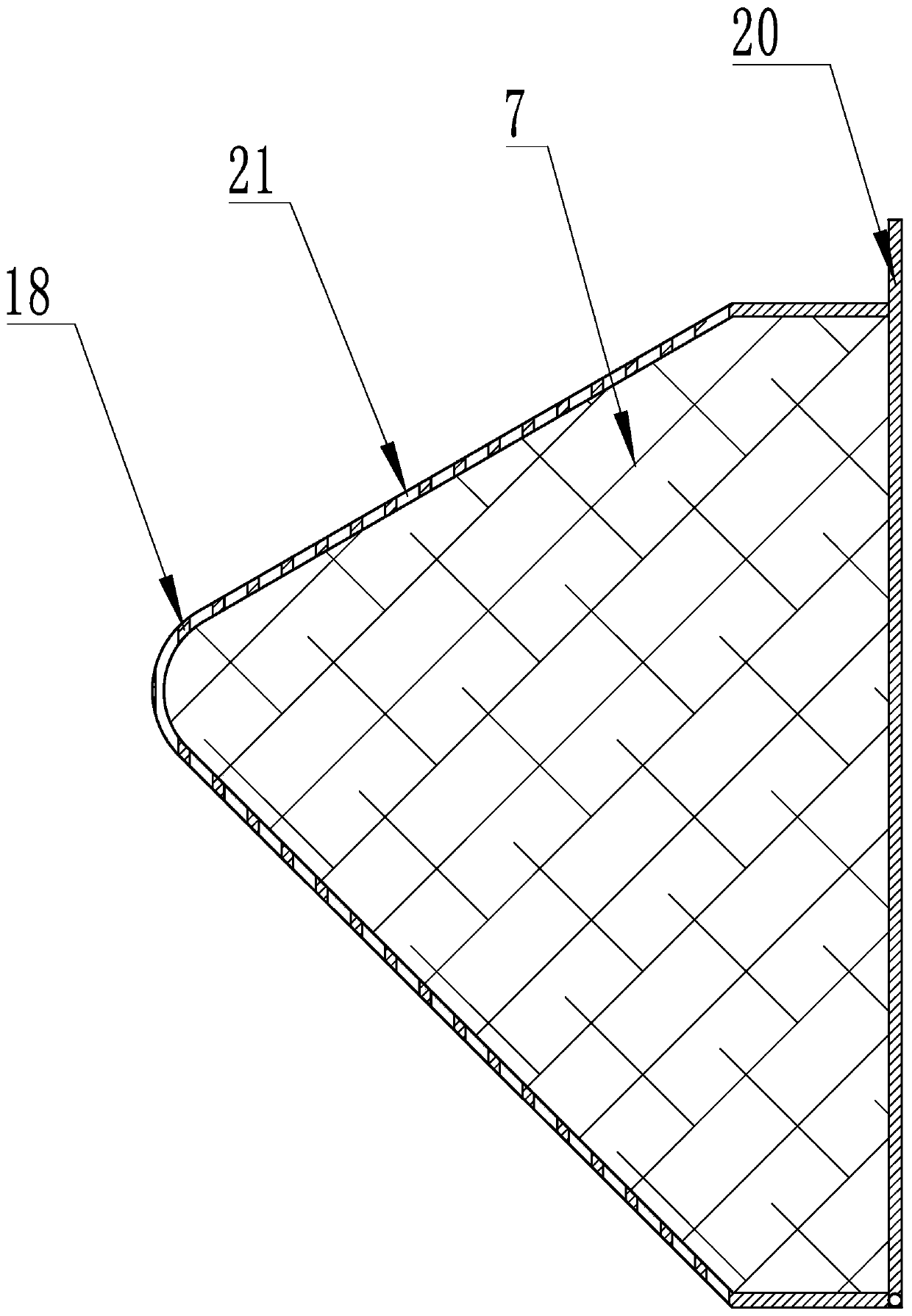

[0037] according to Figure 1 to Figure 2 A domestic waste gasification treatment system with chlorine removal function shown, including a gasifier 11 and a chlorine removal system, is characterized in that the chlorine removal system includes a chlorine fine filter device and a chlorine coarse filter device, the chlorine coarse filter device includes a number of filter plates arranged from top to bottom in the gasification furnace 11, one end of the filter plate is connected with the gasification furnace 11, and the The upward side of the filter plate is inclined downward from the fixed end 1 to the free end 2. The filter plates in the gasification furnace 11 are combined to form a filter plate group, and the filter plate group includes A single-effect filter plate 3 for particles and a multi-effect filter platform 23 for filtering solid particles and chlorine-containing pollutants, the gasification furnace 11 includes a gasification reaction layer 4 and a place for placing t...

Embodiment 2

[0040] according to Figure 1 to Figure 2 As shown, the difference between this embodiment and Example 1 is that the refined chlorine filter device is arranged outside the gasification furnace 11, and the refined chlorine filter device is a fine filter chamber with a dechlorination agent 7 8. The fine filter bin 8 is connected to the gas outlet 9 of the gasifier 11 .

[0041] Compared with Example 1, this embodiment further limits the fine chlorine filter device. The function of setting the chlorine fine filter device outside the gasification furnace 11 is to avoid the high temperature in the furnace to remove chlorine, so as to realize the Medium-high temperature dechlorination of gaseous gas (medium-high temperature dechlorination technology refers to the use of solid-phase dechlorination agent 7 to absorb HCl gas in crude gasification gas at a temperature greater than 500 ° C, and finally realize the separation and separation of chlorine-containing pollutants in flue gas R...

Embodiment 3

[0043] according to Figure 1 to Figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the single-effect filter plate 3 and the multi-effect filter table 23 are arranged alternately from bottom to top in the gasification furnace 11 to form left and right. In the arcuate baffle area, the single-effect filter plate 3 and the multi-effect filter table 23 adjacent to each other form a single filter cycle, and the gasifier 11 is provided with several filter cycles .

[0044] Compared with Embodiment 1, this embodiment further limits the single-effect filter plate 3 and the multi-effect filter table 23, and the single-effect filter plate 3 and the multi-effect filter table 23 are left and right in the gasifier 11 from bottom to top. Arranged alternately to form a bow-shaped baffle area, the upper and lower two adjacent single-effect filter plates 3 and the multi-effect filter table 23 form a single filter cycle, and the function of several filter cycles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com