Internal series perovskite battery assembly and preparation method thereof

A perovskite battery and perovskite technology, applied in the field of solar cells, can solve the problems of reducing battery stability, limiting the stability of perovskite solar cells, and deterioration of perovskite layers, so as to solve the problems of instability, process Simple and easy to control, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

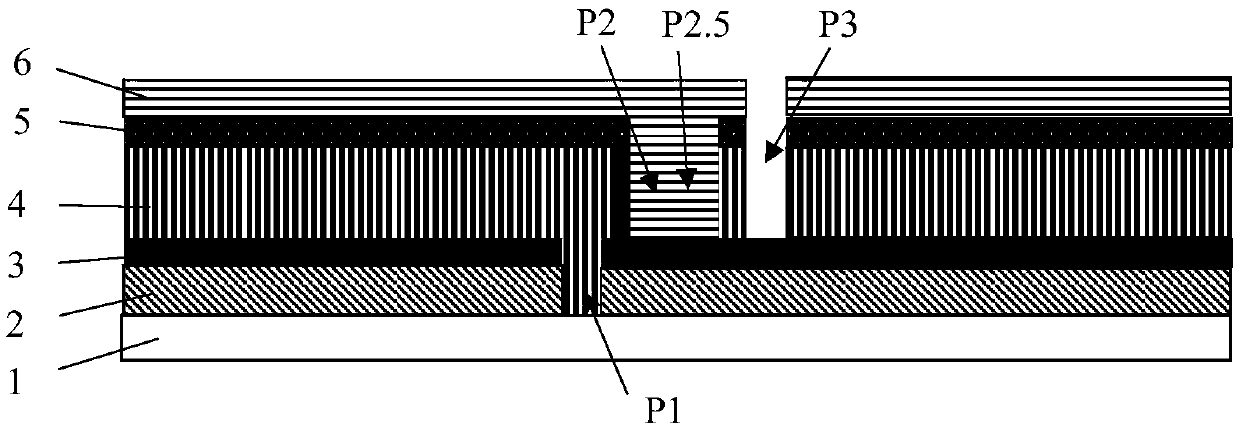

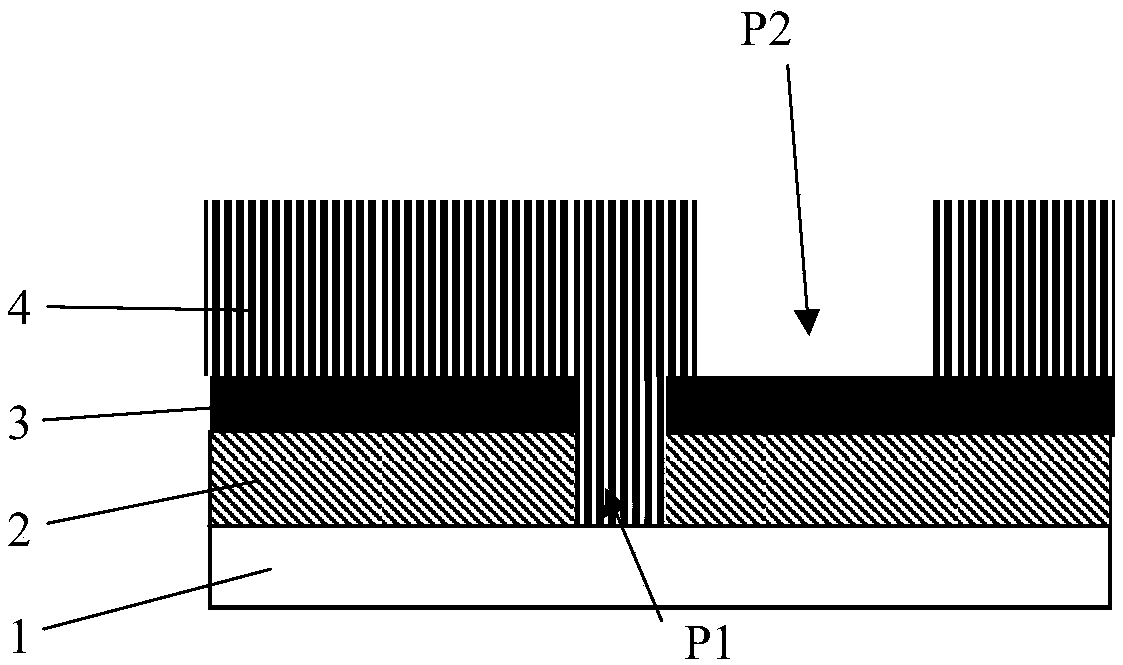

[0030] Please also refer to figure 2 , image 3 as well as Figure 4 As shown, a preferred embodiment of the perovskite battery assembly in series in the present invention, the perovskite battery assembly is sequentially composed of a substrate 1, a conductive layer 2, a front electrical transport layer 3, a perovskite layer 4, The rear electrical transport layer 5 and the rear electrode layer 6 .

[0031] There are n−1 cutting line grooves P1 on the front electrical transmission layer 3 , and the cutting line grooves P1 simultaneously cut off the front electrical transmission layer 3 and the conductive layer 2 without damaging the substrate 1 . The same perovskite material as the perovskite layer is filled in the cutting wire groove P1 and connected with the perovskite layer.

[0032] There are n-1 cutting wire grooves P2.5 on the rear electrical transmission layer 5, each of the cutting wire grooves P2.5 is located on the side of the corresponding cutting wire groove P1,...

Embodiment 2

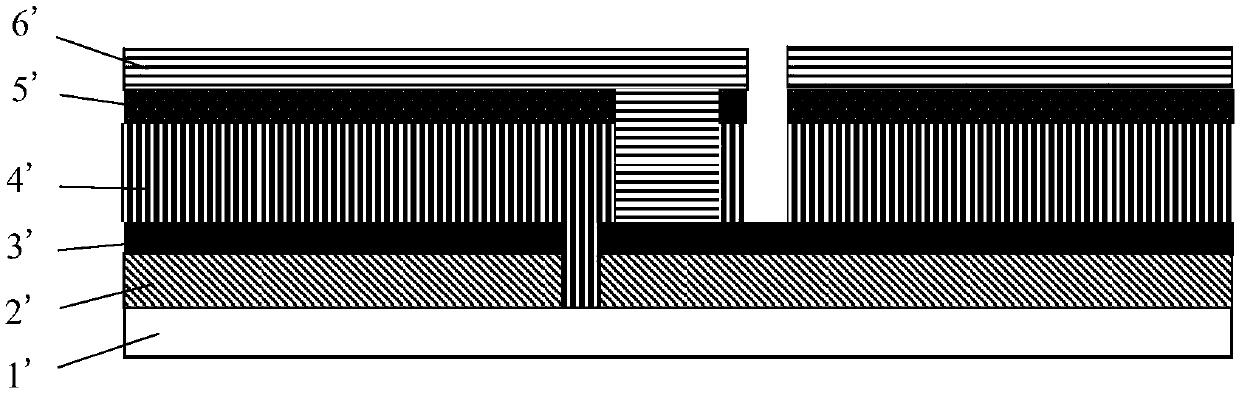

[0035] Please also refer to Figure 5 , Figure 6 as well as Figure 7 As shown, another preferred embodiment of the internal series perovskite cell assembly of the present invention, the perovskite cell assembly is sequentially composed of a substrate 1, a back electrode layer 6, a rear electrical transport layer 5, and a perovskite cell assembly from bottom to top. Mineral layer 4, conductive layer 2, front electrical transmission layer 3.

[0036] There are n−1 cutting line grooves P1 arranged on the rear electrical transmission layer 5 , and the cutting line grooves P1 simultaneously cut the rear electrical transmission layer 5 and the back electrode layer 6 without damaging the substrate 1 . The same perovskite material as the perovskite layer is filled in the cutting wire groove P1 and connected with the perovskite layer.

[0037] There are n-1 cutting line slots P2.5 on the front electrical transmission layer 3, each of the cutting line slots P2.5 is located on the s...

example 3

[0066] A method for preparing an inner tandem perovskite solar cell, comprising the following steps:

[0067] (1) Clean the ITO glass sequentially with detergent, deionized water, acetone, and isopropanol for 30 minutes, and then use N 2 After drying, it was treated with UV O-zone for 5 minutes.

[0068] (2) Preparation of low temperature SnO 2 The thin film acts as an electron transport layer (equivalent to a pre-electron transport layer).

[0069] (3) P1 cutting with laser or mechanical scribing.

[0070] (3) Preparation of perovskite layer.

[0071] (4) P2 cutting with laser or mechanical scribing.

[0072] (5) Preparation of P 3 The HT film is used as a hole transport layer (equivalent to the back electrical transport layer).

[0073] (6) P2.5 cutting with laser or mechanical scribing.

[0074] (6) Evaporate the metal conductive layer Au electrode (equivalent to the back electrode layer).

[0075] (7) P3 cutting with laser or mechanical scribing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com