Positive electrode material and preparation method and application thereof

A cathode material and slurry technology, applied in the field of cathode materials and their preparation, can solve the problems of poor cycle life and low compaction density of lithium iron phosphate materials, achieve excellent coating quality, reduce high-temperature solid-phase sintering temperature and Sintering time, the effect of increasing the compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention firstly discloses a method for preparing a positive electrode material, comprising the following steps:

[0029] Add iron source, lithium source and carbon source (C 6 h 9 NO) n dispersion liquid, obtain slurry;

[0030] Grinding and drying the slurry to obtain a precursor I;

[0031] The precursor I and β-LiAl(SiO 3 ) 2 After mixing, the precursor II is obtained;

[0032] The positive electrode material is obtained by crushing and classifying the precursor II after solid-state sintering under a protective atmosphere.

[0033] Lithium iron phosphate is one of the most researched lithium ion cathode materials at present. Its preparation is generally obtained by mixing iron source, lithium source, and carbon source to prepare a precursor first, and then sintering the precursor. In the present invention, by adding iron source, lithium source, carbon source (C 6 h 9 NO)n dispersion liquid, dried after grinding to obtain carbon-coated precursor I first,...

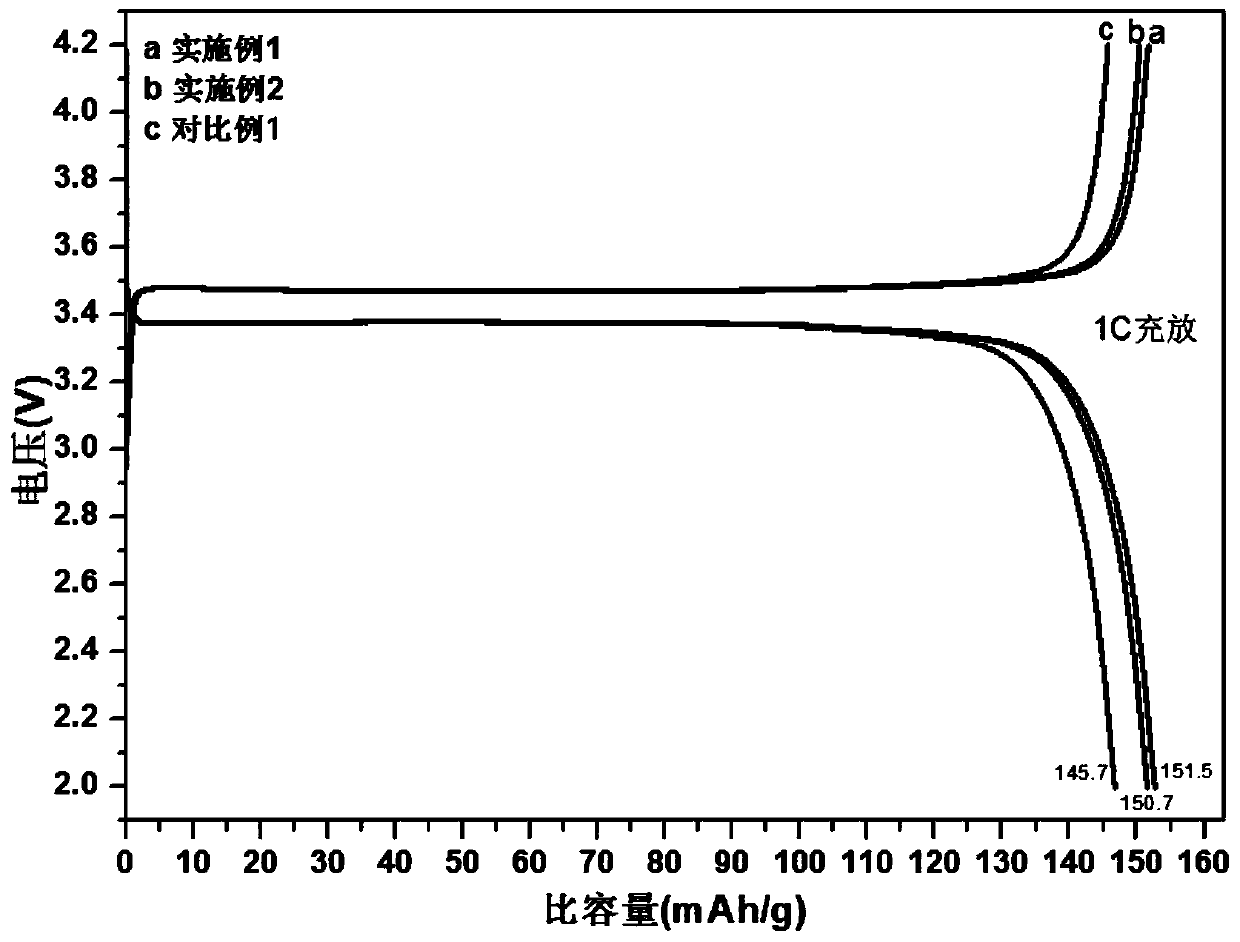

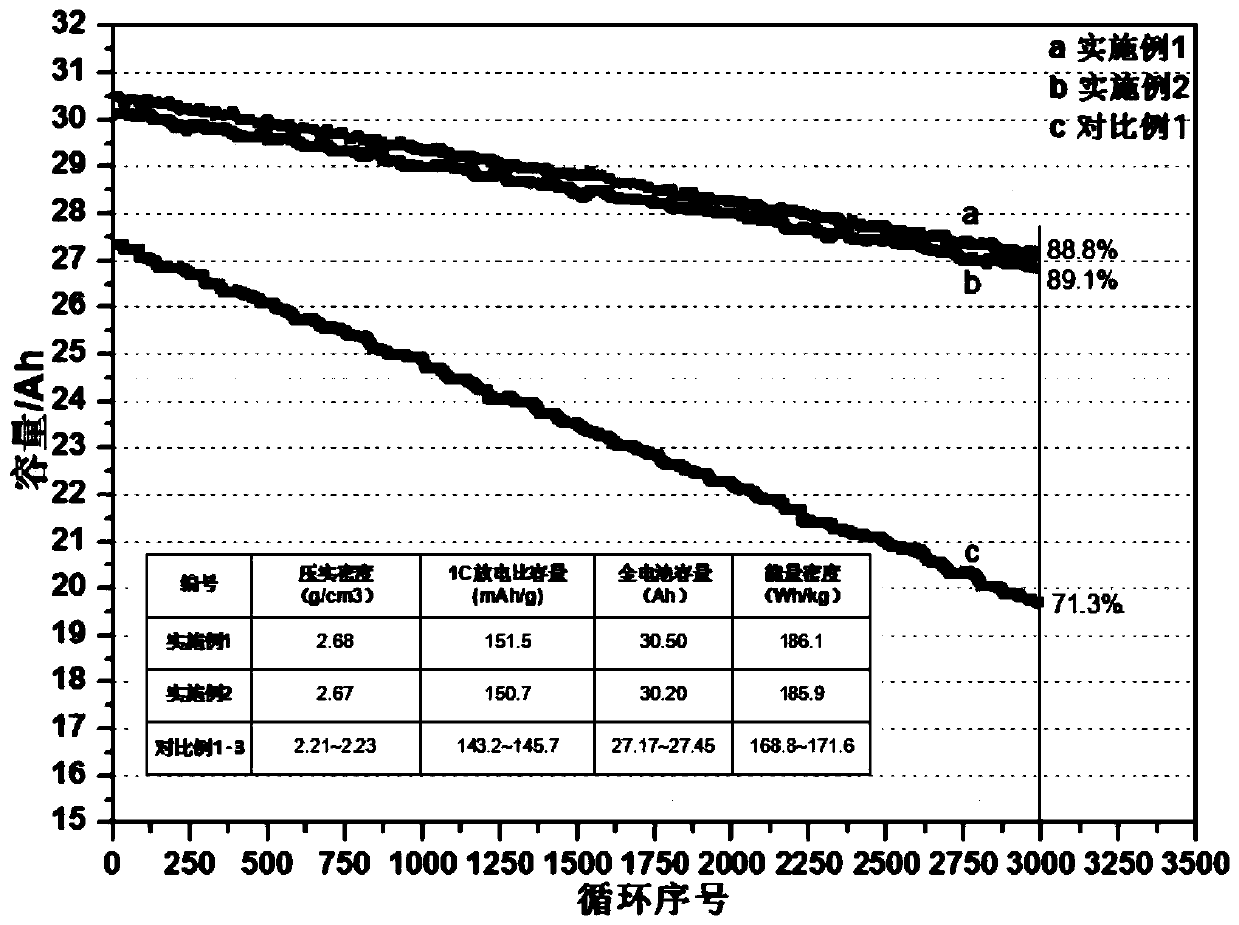

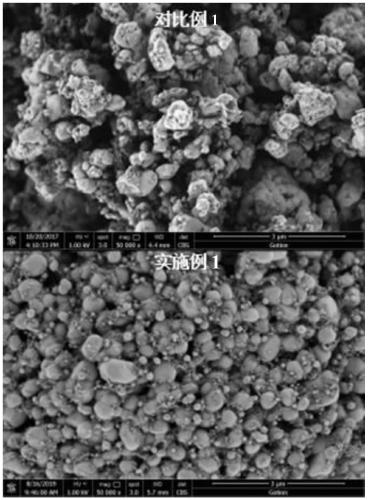

Embodiment 1

[0045] 116g (C 6 h 9 NO) 4000 Add to 5kg pure water and stir well to form a dispersion, then add 3kg FePO to the dispersion 4 , 0.74kg Li 2 CO 3 and 0.29kg C 6 h 12 o 6 , fully stirred evenly and then ground to obtain a mixed slurry with D50=400nm;

[0046] The mixed slurry is dried to obtain the precursor I of lithium iron phosphate, according to the precursor I and β-LiAl(SiO 3 ) 2 The mass ratio of 1:0.003, the precursor Ⅰ and 12.5g β-LiAl (SiO 3 ) 2 Uniformly mixed to obtain precursor II, the precursor II in N 2 After solid-state sintering at 700 °C for 9 hours in the atmosphere, it was pulverized and classified to obtain a composition of LFP / C / β-LiAl(SiO 3 ) 2 The lithium iron phosphate cathode material has a particle size distribution of D10=0.28 μm, D50=1.0 μm, and D100=7.6 μm.

Embodiment 2

[0048] 140g (C 6 h 9 NO) 3000 Add to 5kg pure water and stir well to form a dispersion, then add 2.9kg FePO to the dispersion 4 , 0.74kg Li 2 CO 3 and 0.28kg C 6 h 12 o 6 , fully stirred evenly and then ground to obtain a mixed slurry with D50=433nm;

[0049] The mixed slurry is dried to obtain the precursor I of lithium iron phosphate, according to the precursor I and β-LiAl(SiO 3 ) 2 The mass ratio of 1:0.003, the precursor Ⅰ and 13.8g β-LiAl (SiO 3 ) 2 Uniformly mixed to obtain precursor II, the precursor II in N 2 After solid-state sintering at 700 °C for 9 hours in the atmosphere, it was pulverized and classified to obtain a composition of LFP / C / β-LiAl(SiO 3 ) 2 The lithium iron phosphate cathode material has a particle size distribution of D10=0.33 μm, D50=1.2 μm, and D100=8.4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com