Leather-based pressure sensor for recording walking track, and preparation method and application thereof

A pressure sensor and leather technology, which is applied in the measurement, instrument, and force measurement of the property force of piezoelectric resistance materials, to achieve the effect of improving compressive stress, enriching the multi-functional application of leather, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

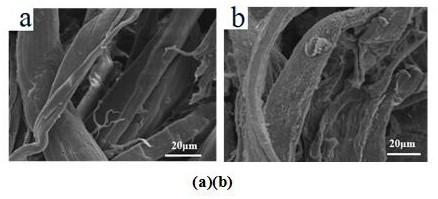

[0044] Step 1: Take the mass ratio of MWCNT / RGO as 3:0, ultrasonically disperse in NMP to prepare 0.2 mg / mL solution, and then mix with Al 3+ The solution is mixed, where Al 3+ / C is 0.01mmol / mg respectively, pH is 3, stirring reaction at room temperature for 2h, ultrasonically immersing the pigskin in 30 mL mixed solution, drying at 50°C to semi-dry, hot pressing with an electric iron for 10 min to reassemble the collagen surface ;

[0045] Step 2: Cut two pieces of conductive leather of different sizes to make the first leather and the second leather respectively, and use polyvinyl alcohol as the adhesive layer to make a sandwich structure pressure sensor;

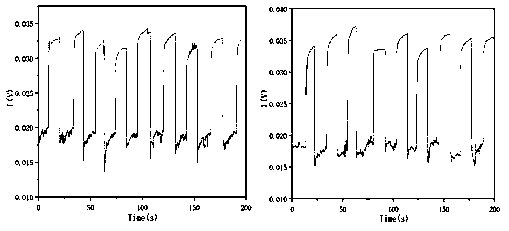

[0046] Step 3: Assemble the pressure sensor of a single unit array into a dense array pressure sensor in a circular array, place the dense array pressure sensor on the sole of the shoe, and apply and release the current signal generated by the pressure deformation of the dense array pressure sensor Record walking patte...

Embodiment 2

[0048] Step 1: Take MWCNT / RGO with a mass ratio of 3:1, ultrasonically disperse in NMP to prepare a 0.2 mg / mL solution, and then mix with Cr 3+ The solution is mixed, where Cr 3+The / C is 0.02 mmol / mg, the pH is 11, and the reaction is stirred at room temperature for 3 h. The sheepskin is ultrasonically assisted in immersion in 30 mL of the mixed solution, dried at 50 °C and semi-dried, and hot-pressed with an electric iron for 30 min to reassemble the collagen surface;

[0049] Step 2: Cut two pieces of conductive leather of different sizes to make the first leather and the second leather respectively, and use polyvinyl chloride as the bonding layer to make a sandwich structure pressure sensor;

[0050] Step 3: Place the pressure sensor of a single unit array on the sole of the shoe, and record the walking pattern by applying and releasing the current signal generated by the pressure deformation of the single unit array pressure sensor.

Embodiment 3

[0052] Step 1: Take MWCNT / RGO with a mass ratio of 3:1, ultrasonically disperse in NMP to prepare a 0.2 mg / mL solution, and then mix with Co 2+ The solution is mixed, where Co 2+ / C is 0.08 mmol / mg, pH is 7, stirred and reacted at room temperature for 2.5 h, ultrasonic-assisted immersion in 30 mL of the mixed solution, dried at 50 °C and semi-dried, hot-pressed with an electric iron for 20 min to make the collagen surface secondary assembly;

[0053] Step 2: Cut two pieces of conductive leather of different sizes to make the first leather and the second leather respectively, and use polyurethane as the bonding layer to make a sandwich structure pressure sensor;

[0054] Step 3: Assemble the pressure sensors of a single unit array into a dense array pressure sensor in an irregular array, place the dense array pressure sensor on the sole of the shoe, and apply and release the current generated by the pressure deformation of the dense array pressure sensor The signal records th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com