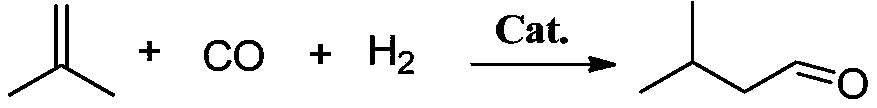

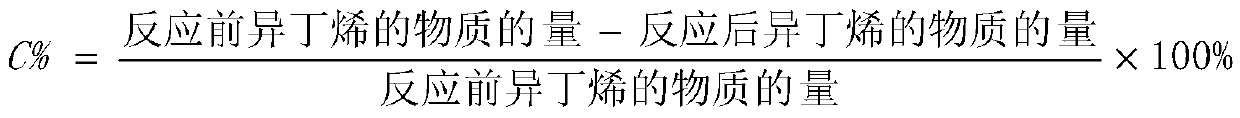

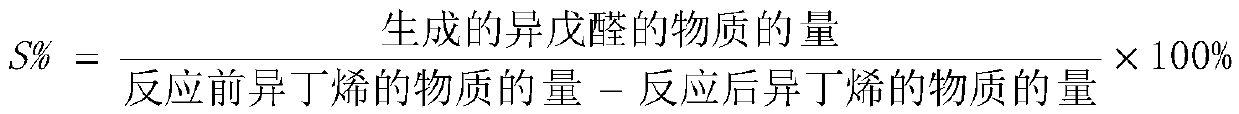

Hydroformylation catalyst as well as preparation method and application thereof

A hydroformylation catalyst and catalyst technology, applied in the direction of carbon monoxide reaction preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of easy loss of active components, affecting application prospects, Conversion rate and selectivity are not high, to achieve the effect of reducing separation cost, long service life and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Above-mentioned hydroformylation catalyst can be prepared by following method, and this preparation method comprises the following steps:

[0046] The first metal salt, the second metal salt and the third metal salt are prepared into a mixed salt solution as an immersion solution, the first metal salt is a metal salt of Rh, and the second metal salt is a metal of Ir, Ru, Os, Pt, and Pd One or more of the salts, the third metal salt is one or more of the metal salts of Mo, Zn, Mn, Fe, Co, V, Cu;

[0047] The carrier is immersed in the above impregnating solution, and the catalyst for isobutene hydroformylation is obtained through the steps of drying, calcining and reduction.

[0048] In some embodiments, the above-mentioned first metal salt, second metal salt and third metal salt may be nitrate, acetate, sulfate, chloride or oxalate of the corresponding metal. For example, the first metal salt may be rhodium nitrate, rhodium sulfate, rhodium acetate, rhodium chloride, o...

Embodiment 15

[0062] Example 1 5.0%Rh-0.1%Ir-1.0%Mo / Al 2 o 3 Catalyst preparation

[0063] Weigh 10g Al 2 o 3 Carrier, according to the mass percentage composition of carrier in catalyzer is 80.0% the quality of rhodium chloride, iridium chloride and molybdenum nitrate required for 5.0%Rh, 0.1%Ir, 1.0%Mo in the calculation catalyst, Each metal salt is weighed according to the calculated mass, and each metal salt is prepared into a mixed solution as an impregnating solution.

[0064] Will Al 2 o 3 The carrier was added to the impregnating solution at room temperature, stirred and adsorbed, dried at 80° C. for 12 hours after sufficient adsorption, and calcined at 500° C. for 4 hours to obtain a catalyst precursor.

[0065] The above catalyst precursor was placed in a hydrogen atmosphere at 200 ° C for 12 hours to obtain a 5.0% Rh-0.1% Ir-1.0% Mo / Al 2 o 3 Catalyst, denoted as catalyst A.

Embodiment 2

[0066] Example 2 10.0%Rh-0.05%Ru-0.05%Zn / ZrO 2 Catalyst preparation

[0067] Weigh 10g ZrO 2 Carrier, according to the mass percentage composition of carrier in catalyst is 80.0% the quality of the required rhodium nitrate, ruthenium chloride and zinc acetate in calculating catalyst load mass percentage composition 10.0%Rh, 0.05%Ru, 0.05%Zn, according to Calculate the mass obtained by weighing each metal salt, and prepare a mixed solution of each metal salt as an impregnating solution.

[0068] ZrO 2 The carrier was added into the impregnating solution at room temperature and stirred for adsorption. After fully adsorbed, it was dried at 120° C. for 4 hours, and calcined at 300° C. for 6 hours to obtain a catalyst precursor.

[0069] The above catalyst precursor was placed in a hydrogen atmosphere at 300°C for 2 hours to obtain a 10.0%Rh-0.05%Ru-0.05%Zn / ZrO 2 Catalyst, denoted as catalyst B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com