Ultraviolet cross-linked low-smoke, halogen-free and flame-retardant polyolefin material and preparation method thereof

A technology of photocrosslinking and ultraviolet light, applied in the direction of plastic/resin/wax insulators, organic insulators, electrical components, etc., can solve the problems of low extrusion speed, insufficient crosslinking degree, volatilization and decomposition of photosensitizers and other materials, and achieve The effect of increasing the degree of cross-linking and improving the thermal elongation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

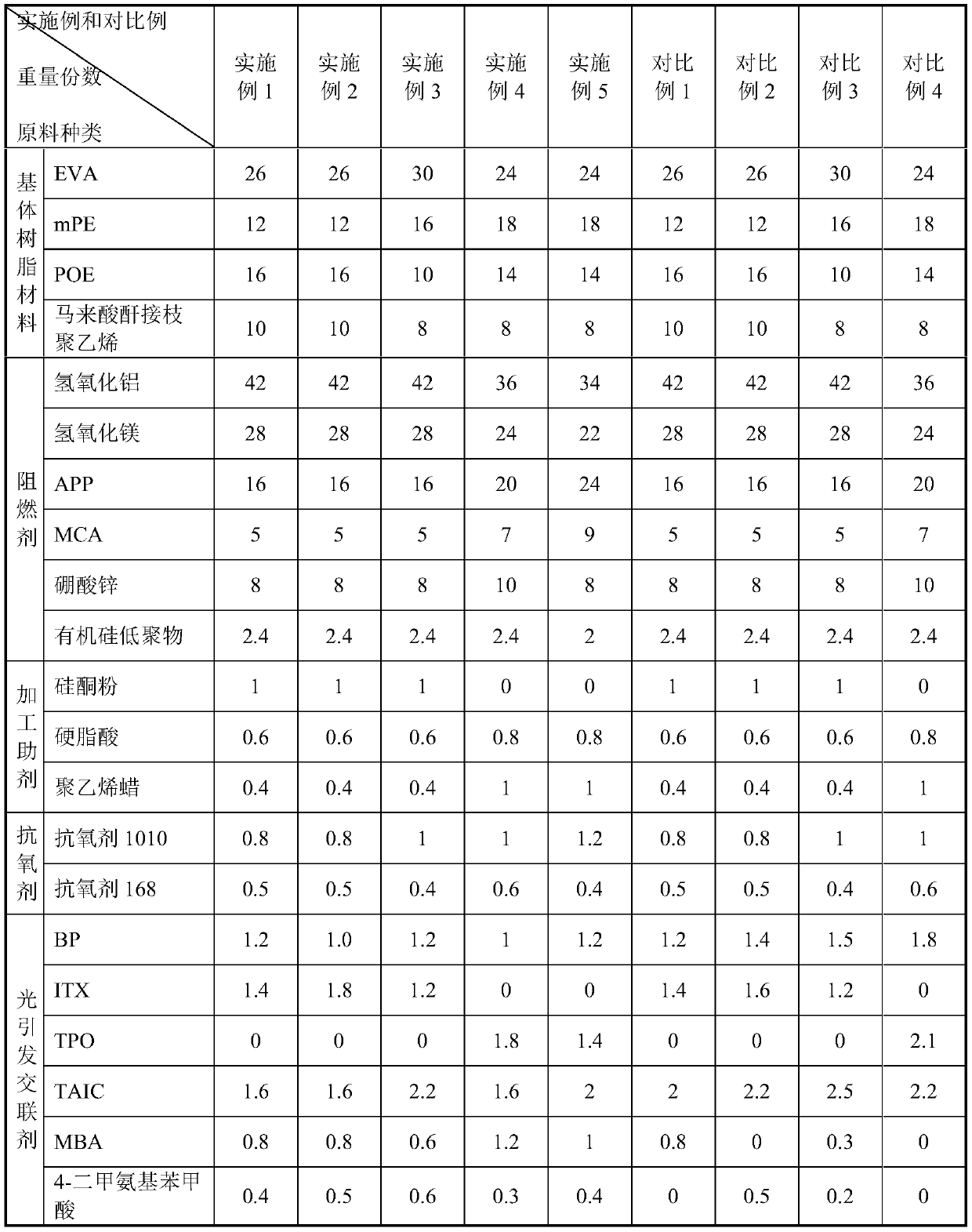

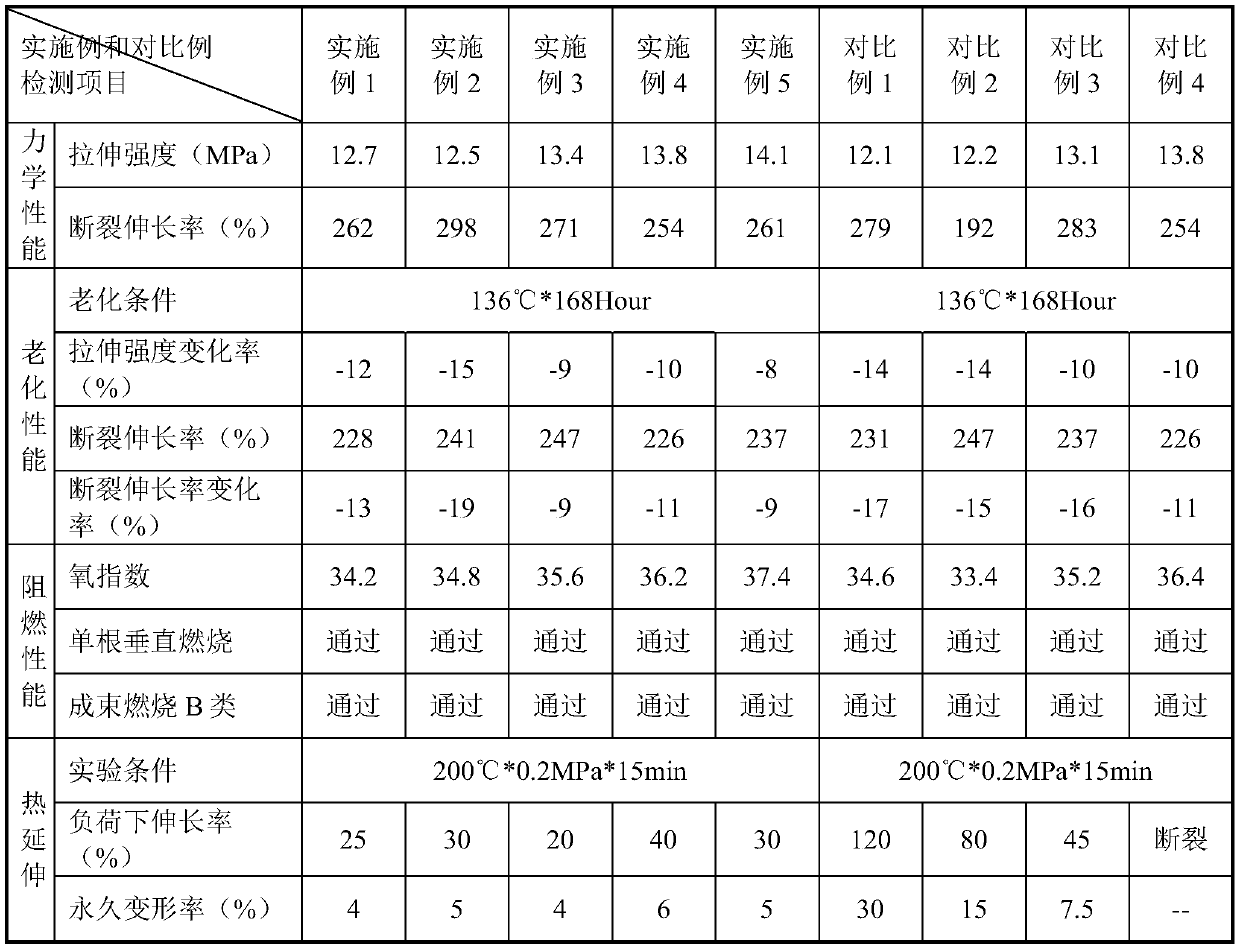

[0029] The concrete formula of embodiment 1-5 provided by the invention and comparative example 1-4 is as shown in table 1:

[0030] The preparation method of embodiment 1-5 provided by the invention is identical with comparative example 1-4, concrete preparation method:

[0031] Heat and stir the photo-initiated cross-linking agent in the mixer according to the metering ratio, the stirring temperature is 55°C, batching once every 2 hours, and send the photo-initiated cross-linking agent to the auxiliary feeding of the twin-screw extruder after metering by the metering pump Mouth injection, mixed with other raw materials o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com