Low-density liquid crystal polymer and preparation method thereof

A liquid crystal polymer, low-density technology, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of limited application, high density of liquid crystal polymers, etc., and achieve the effect of density reduction and good thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

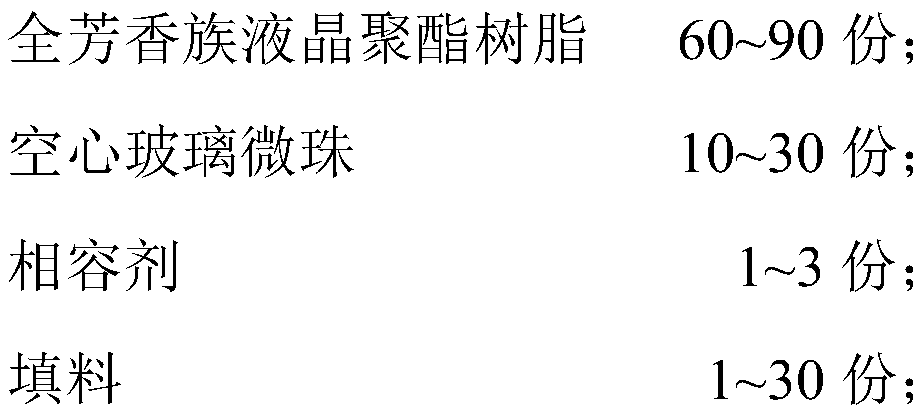

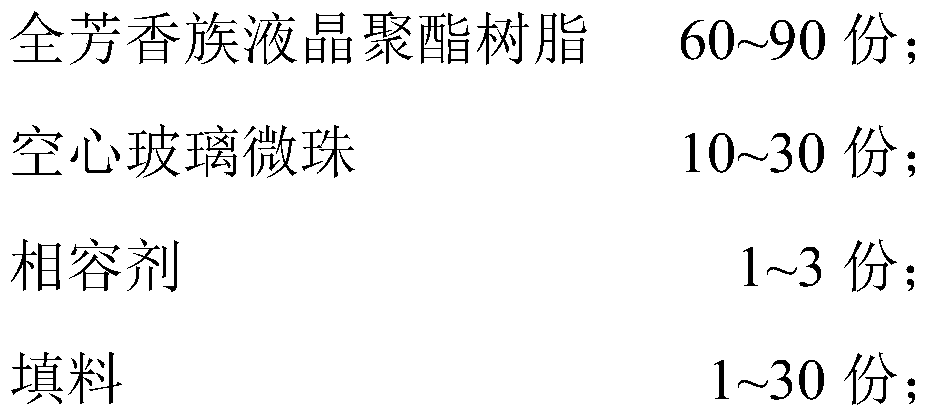

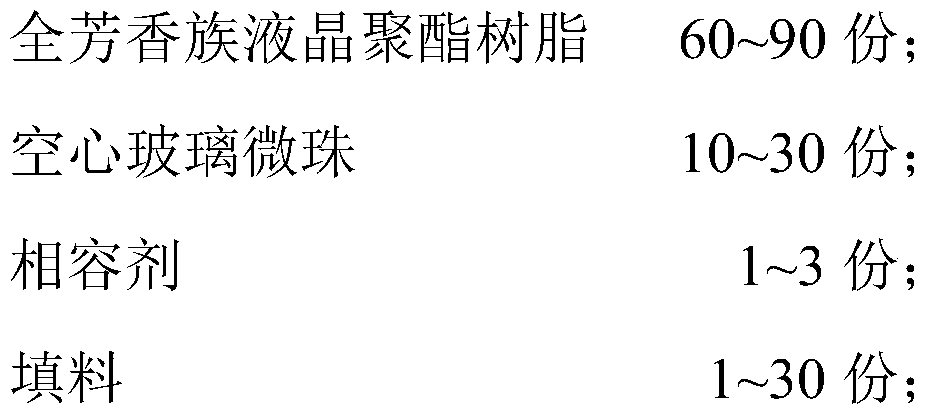

[0047] Correspondingly, the embodiment of the present invention also provides a method for preparing a low-density liquid crystal polymer. The method comprises the steps of:

[0048] S01. Weigh each component according to the low-density liquid crystal polymer;

[0049] S02. Drying the wholly aromatic liquid crystal polyester resin, the hollow glass microspheres, the compatibilizer and the filler;

[0050] S03. Mixing the dried wholly aromatic liquid crystal polyester resin, the hollow glass microspheres, the compatibilizer, and the filler to obtain a first mixture;

[0051] S04. Melt and knead the first mixture, then extrude, draw, cool, and granulate to obtain the low-density liquid crystal polymer.

[0052] The preparation method of the low-density liquid crystal polymer provided by the present invention is to dry and mix the wholly aromatic liquid crystal polyester resin, the hollow glass microspheres, the compatibilizer and the filler, and then The mixture is melted an...

Embodiment 1

[0067] A low-density liquid crystal polymer

[0068] The low-density liquid crystal polymer includes such as 73 parts of wholly aromatic liquid crystal polyester resin; 25 parts of hollow glass microspheres; 1 part of compatibilizer; 1 part of filler; wherein, the diameter of the hollow glass microspheres is 20 μm, model For 3M iM16K.

[0069] The preparation method of the low-density liquid crystal polymer, the preparation method includes the following steps: weighing each component according to the low-density liquid crystal polymer; The beads, the compatibilizer and the filler were dried at 120°C for 6 hours; the dried fully aromatic liquid crystal polyester resin, the hollow glass microspheres, the compatibilizer and the The filler is put into an automatic mixer and mixed evenly to obtain the first mixture; the first mixture is put into a twin-screw extruder for melting and kneading, and then extruded, drawn, cooled, and granulated to produce the low-density liquid crysta...

Embodiment 2

[0071] A low-density liquid crystal polymer

[0072] The low-density liquid crystal polymer includes such as 83 parts of wholly aromatic liquid crystal polyester resin; 15 parts of hollow glass microspheres; 1 part of compatibilizer; 1 part of filler; wherein, the diameter of the hollow glass microspheres is 20 μm, model For 3M iM16K.

[0073] The preparation method of the low-density liquid crystal polymer, the preparation method includes the following steps: weighing each component according to the low-density liquid crystal polymer; The beads, the compatibilizer and the filler were dried at 120°C for 6 hours; the dried fully aromatic liquid crystal polyester resin, the hollow glass microspheres, the compatibilizer and the The filler is put into an automatic mixer and mixed evenly to obtain the first mixture; the first mixture is put into a twin-screw extruder for melting and kneading, and then extruded, drawn, cooled, and granulated to produce the low-density liquid crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com